Resin molded sliding bearing and manufacturing method thereof, and tubing pump and manufacturing method thereof

A sliding bearing and resin forming technology, applied in sliding contact bearings, rotating bearings, bearings, etc., can solve problems such as quality deterioration, bearing scars, bearing deformation, etc., to reduce gear noise, eliminate high-range noise, and reduce noise. The effect of gear noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0065] refer to figure 1 A method of manufacturing the sliding bearing according to the first embodiment of the present invention will be described. Sliding bearings are bearings that receive the shaft on the sliding surface. Since the shaft is used in a state where the shaft floats on an oil film, an oil film must be formed during use.

[0066] As the existing method of providing a recess for oil storage, there are methods of providing an annular groove on the shaft and a method of providing an annular groove on the inner periphery of the bearing, etc., but in the above methods, secondary processing is required, so there are manufacturing The disadvantage of high cost. In addition, as a method that does not require secondary processing, there is a method of forming a recess for oil storage by using an overpress method, but there is a disadvantage that the quality deteriorates due to scratches or deformation on the inner diameter.

[0067] In the manufacturing method of the ...

Embodiment 1

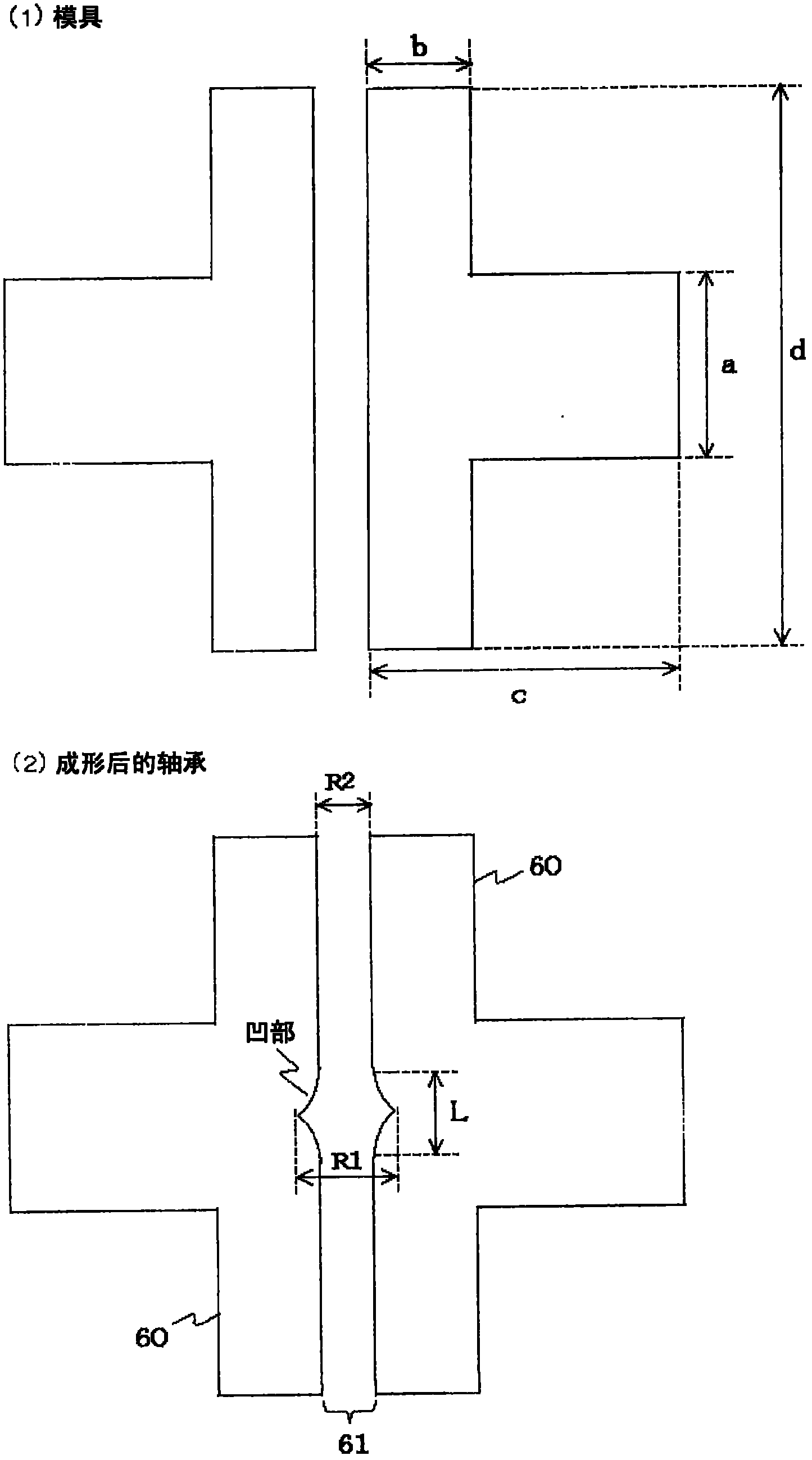

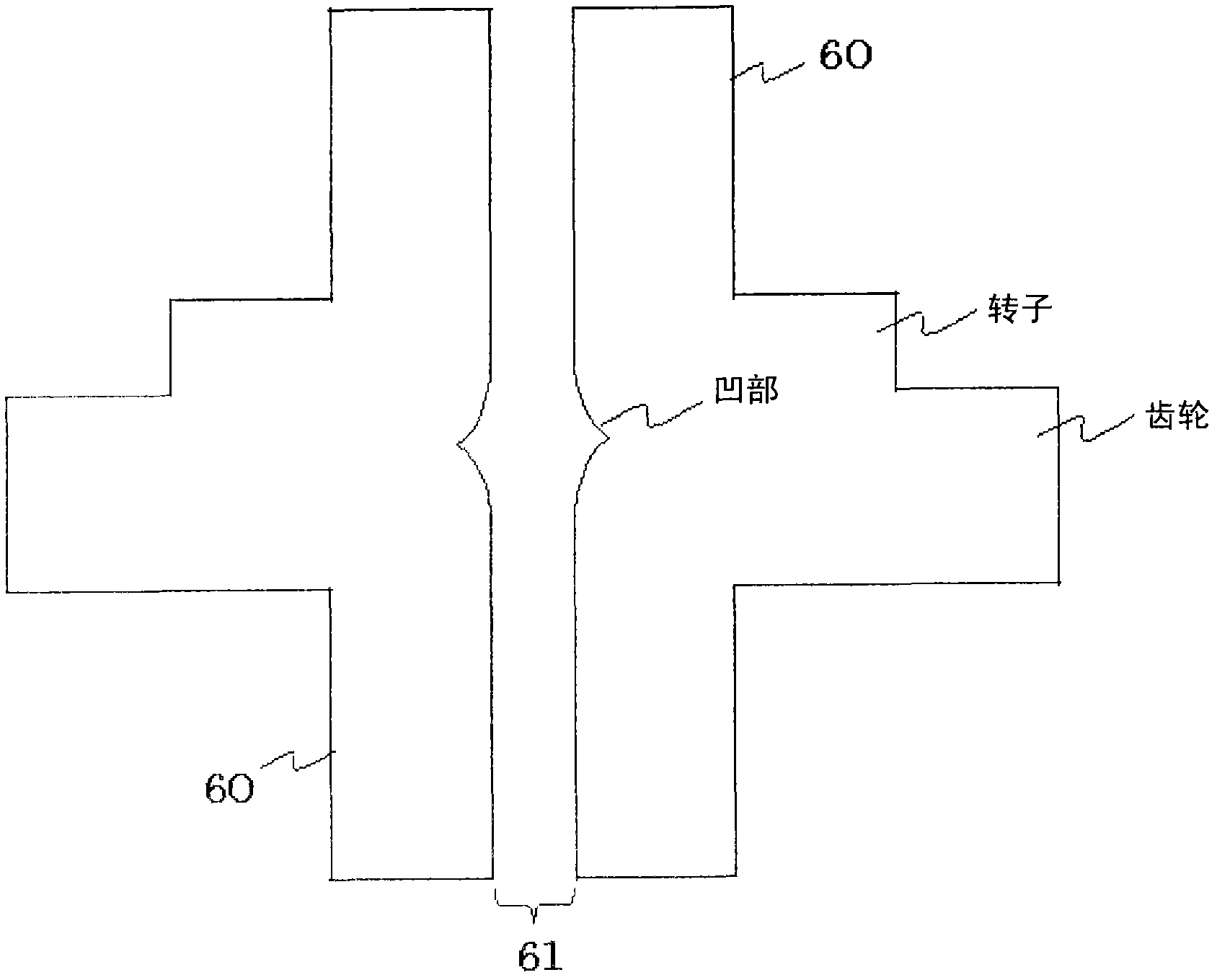

[0074] to use figure 1 The mold shown in (1) is manufactured with figure 1 An example of the resin-molded sliding bearing used for the oil-reserving recess shown in (2) will be described. here, in will figure 1 (1) The dimensions of the mold shown in (1) were set to a=8mm, b=5mm, c=15mm, and d=20mm, and when POM resin (polyacetal) was used as the resin, it was verified that R2≒4.03mm could Form R1≒4.13-4.33 mm, that is, a recessed portion having a groove depth ((R1-R2) / 2) of 50-150 μm and a length L of 5-6 mm. As can be seen from the above, as the conditions for forming a desired concave portion, it is preferable to set c≧3b and a≧2L, for example.

no. 2 approach

[0076] In a second embodiment of the present invention, a method of manufacturing a tube pump using the method of manufacturing a sliding bearing according to the first embodiment will be described.

[0077] (1) Structure of tube pump

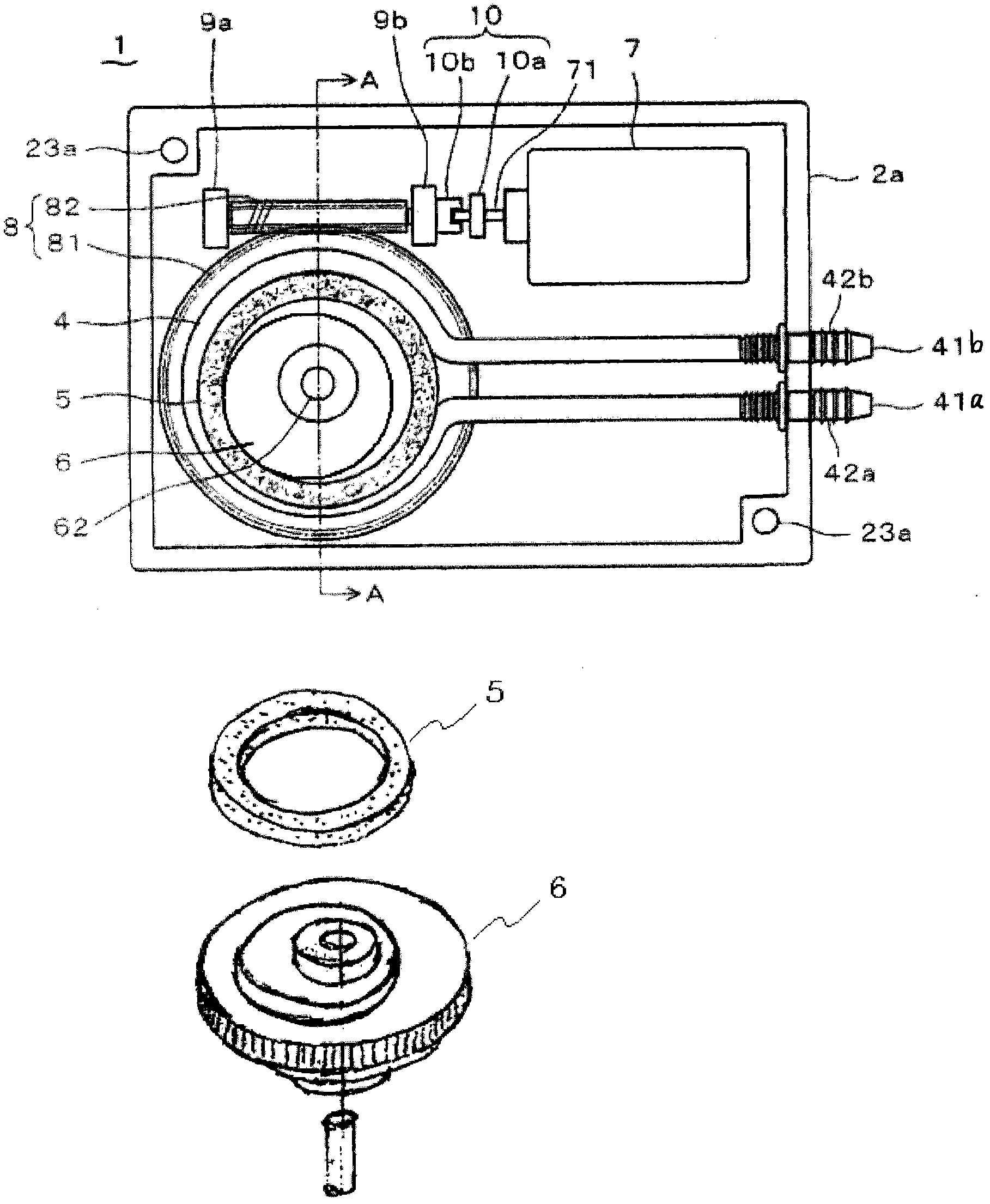

[0078] use Figure 3 ~ Figure 5 The structure of the tube pump will be described. Such as Figure 3 ~ Figure 5 As shown, the tube pump 1 is housed in a frame 2 serving as a pump casing. The frame body 2 includes a bottomed box-shaped frame body body 2 a having an opening, and a frame body cover 2 b covering the opening of the frame body body 2 a.

[0079] The tube pump 1 includes a pump housing 3 in which a cylindrical chamber 31 is formed, a pipe member 4 , an annular pressing member 5 , an eccentric rotor 6 , and a motor 7 . The pump casing 3 also serves as the frame cover 2b. The pipe 4 is arranged in a ring shape along the inner peripheral surface 32 of the cylindrical chamber 31 , has a fluid inlet 41 a at one end, and has a fluid out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com