Microwave-assisted processing method for controlling quality deterioration of minced fillet products during refrigerating process

A technology of surimi products and surimi, which is applied in the field of microwave-assisted processing, can solve problems such as limited shelf life, microbial infection, and quality deterioration, and achieve the effect of reducing quality deterioration and reducing the number of initial microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

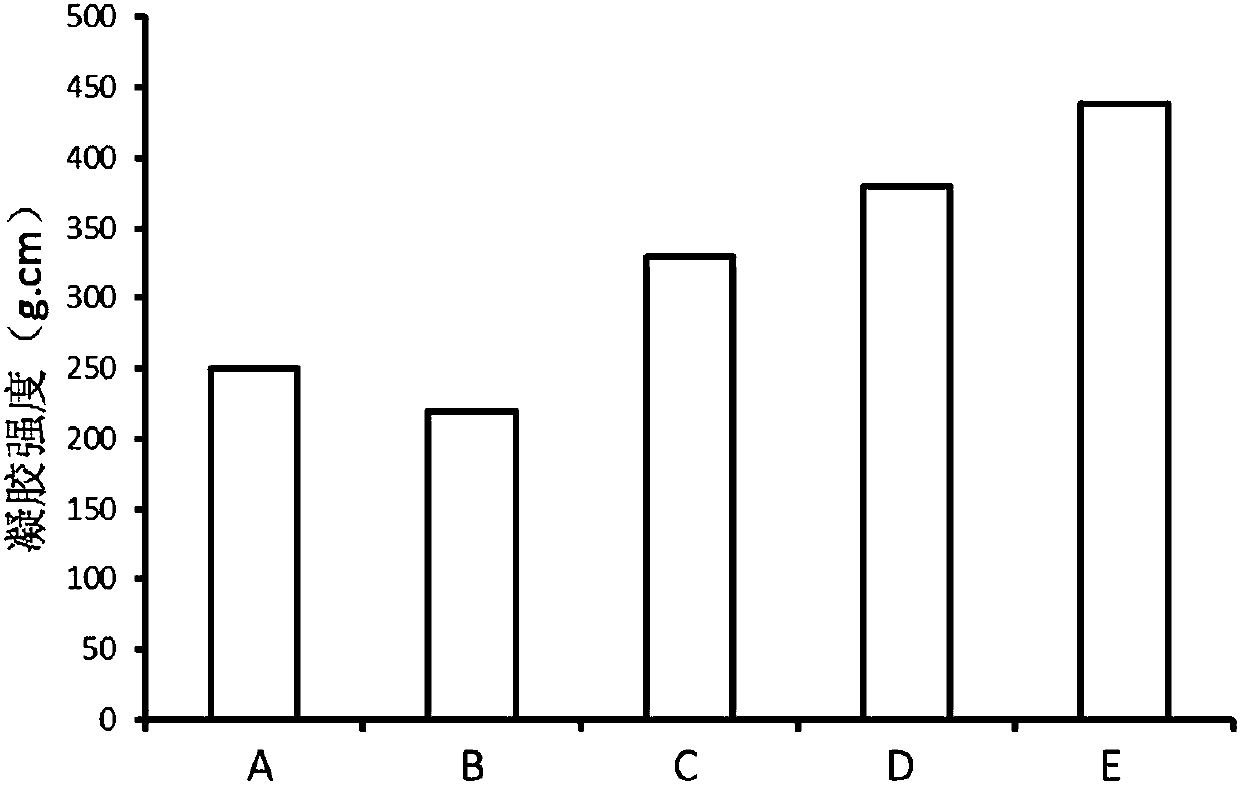

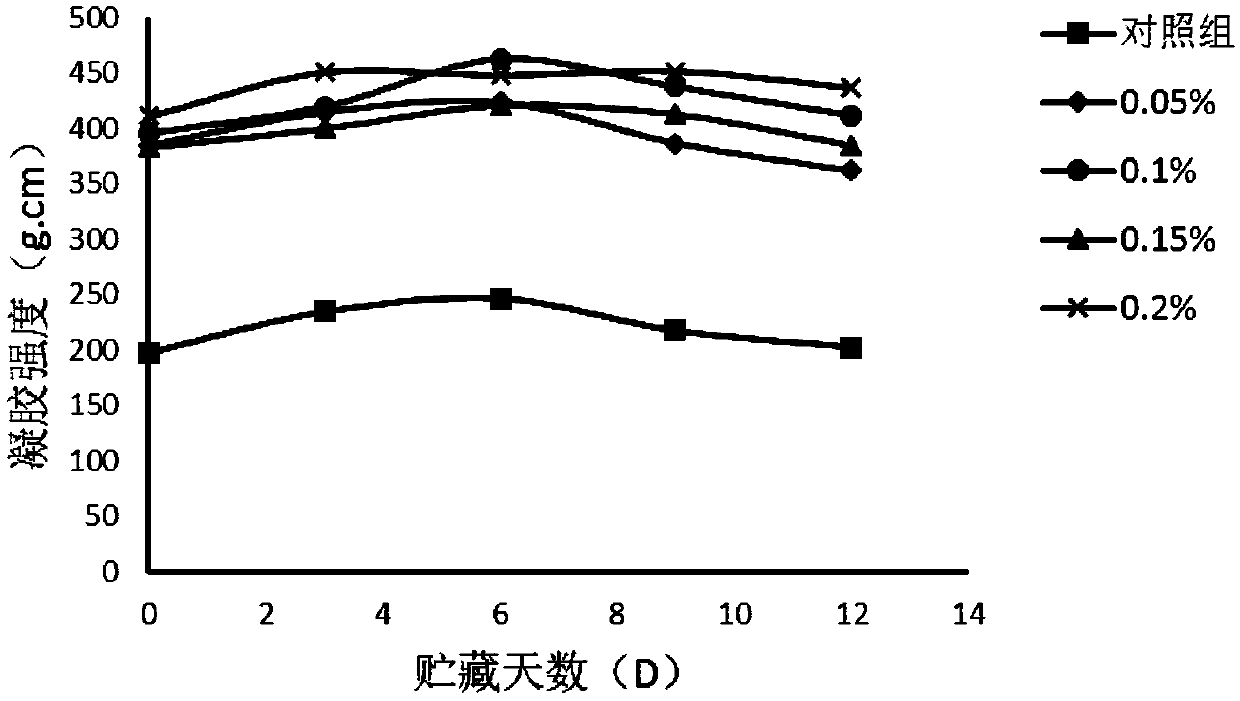

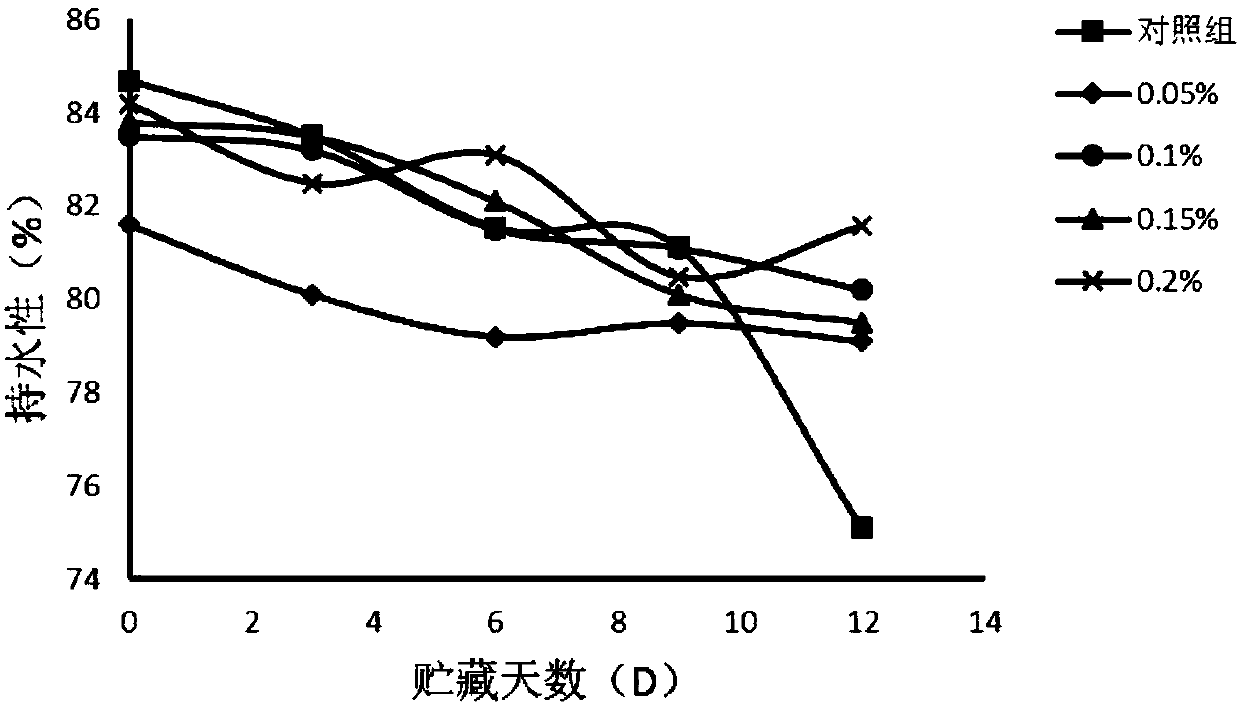

Examples

Embodiment 1

[0040] Take this example as a comparison.

[0041] 1) Preparation of fresh surimi: remove the head, scales, skin and viscera of fresh silver carp, then manually harvest the meat, grind the fish meat with a meat grinder and sieve the fish bones. Rinse the harvested fish twice with tap water below 5°C with a volume 5 times the mass of the fish meat, and then rinse once with tap water below 5°C containing 0.3% (w / v, g / 100mL) NaCl. After standing for 3 minutes, pour off the water and surface impurities. Squeeze and dehydrate with gauze until the moisture is 80%-85% (w / w).

[0042]2) Chop and mix: prepare the prepared surimi in portions of 600 g, and place them in an ice-water bath below 10°C for use. The surimi was chopped in a high-speed chopping machine of Shanghai Shenfa Machinery Co., Ltd. at a low temperature of 2-6°C for 2 minutes at a low speed, and the chopping was stopped every 30s for 10s during the process of chopping. Add 18g of edible salt to it after the air chopp...

Embodiment 2

[0046] 1) Preparation of fresh surimi: remove the head, scales, skin and viscera of fresh silver carp, then manually harvest the meat, grind the fish meat with a meat grinder and sieve the fish bones. Rinse the harvested fish twice with tap water below 5°C with a volume 5 times the mass of the fish meat, and then rinse once with tap water below 5°C containing 0.3% (w / v) NaCl for 5 minutes each time, and let it stand After 3 minutes, pour off the water and surface impurities. Squeeze and dehydrate with gauze until the moisture is 80%-85% (w / w).

[0047] 2) Air chopping: 600g of surimi was chopped in a high-speed chopping machine of Shanghai Shenfa Machinery Co., Ltd. at a low temperature of about 4°C for 2 minutes, and the chopping was stopped every 30s for 10s until the fish Mi Bao group sticky wall and no hard particles.

[0048] 3) Salt chopping: Weigh 3% edible salt of surimi mass, about 18g, and evenly add it to the surimi that has been empty-cut, and chop it with salt f...

Embodiment 3

[0052] 1) Preparation of fresh surimi: remove the head, scales, skin and viscera of fresh silver carp, then manually harvest the meat, grind the fish meat with a meat grinder and sieve the fish bones. Rinse the harvested fish twice with tap water below 5°C with a volume 5 times the mass of the fish meat, and then rinse once with tap water below 5°C containing 0.3% (w / v, g / 100mL) NaCl. After standing for 3 minutes, pour off the water and surface impurities. Squeeze and dehydrate with gauze until the moisture is 80%-85% (w / w).

[0053] 2) Chop and mix: prepare the prepared surimi in portions of 600 g, and place them in an ice-water bath below 10°C for use. The surimi was chopped in a high-speed chopping machine of Shanghai Shenfa Machinery Co., Ltd. at a low temperature of 2-6°C for 2 minutes at a low speed, and the chopping was stopped every 30s for 10s during the process of chopping. Add 18g of edible salt to it after the air chopping is completed, and chop the salt in the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com