Smectic state liquid crystal dyeing color display device

A display and smectic technology, which is applied to instruments, nonlinear optics, optics, etc., can solve the problems of complex peripheral drive circuits of display devices, unsatisfactory display effects, and the impact of lightness of display devices, etc., to improve the display effect. , the effect of eliminating parallax defects, production process complexity and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

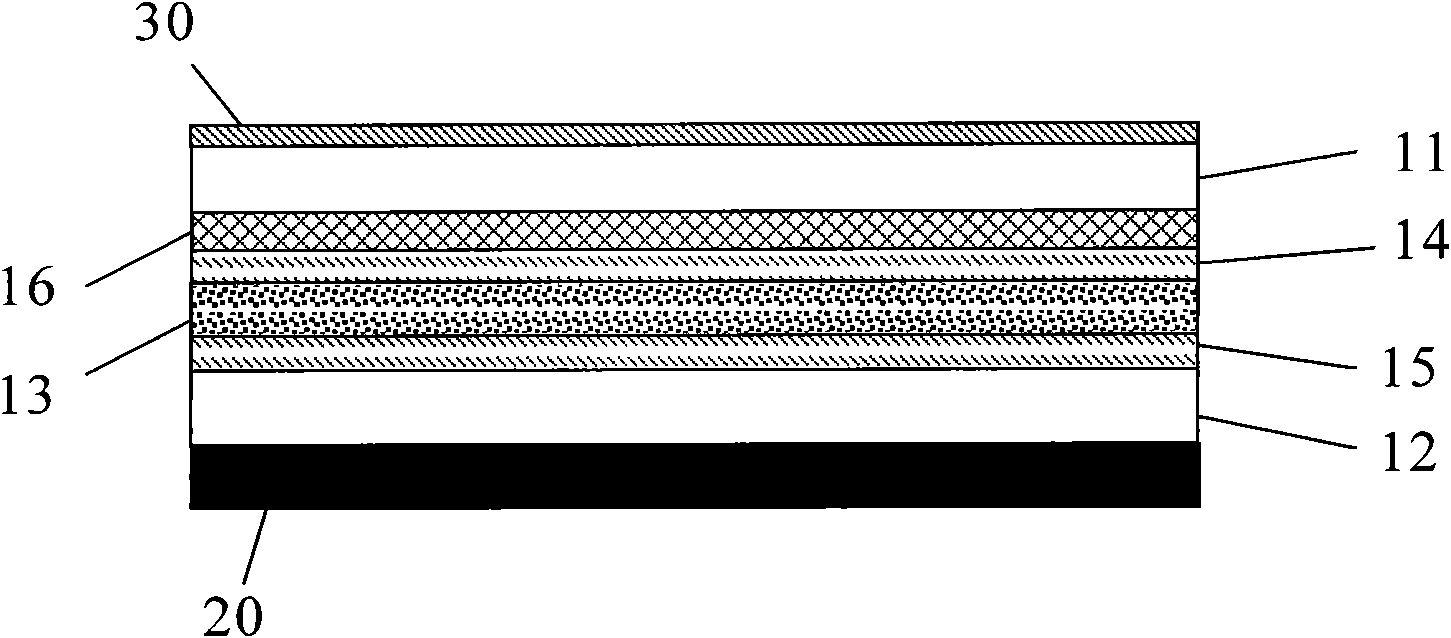

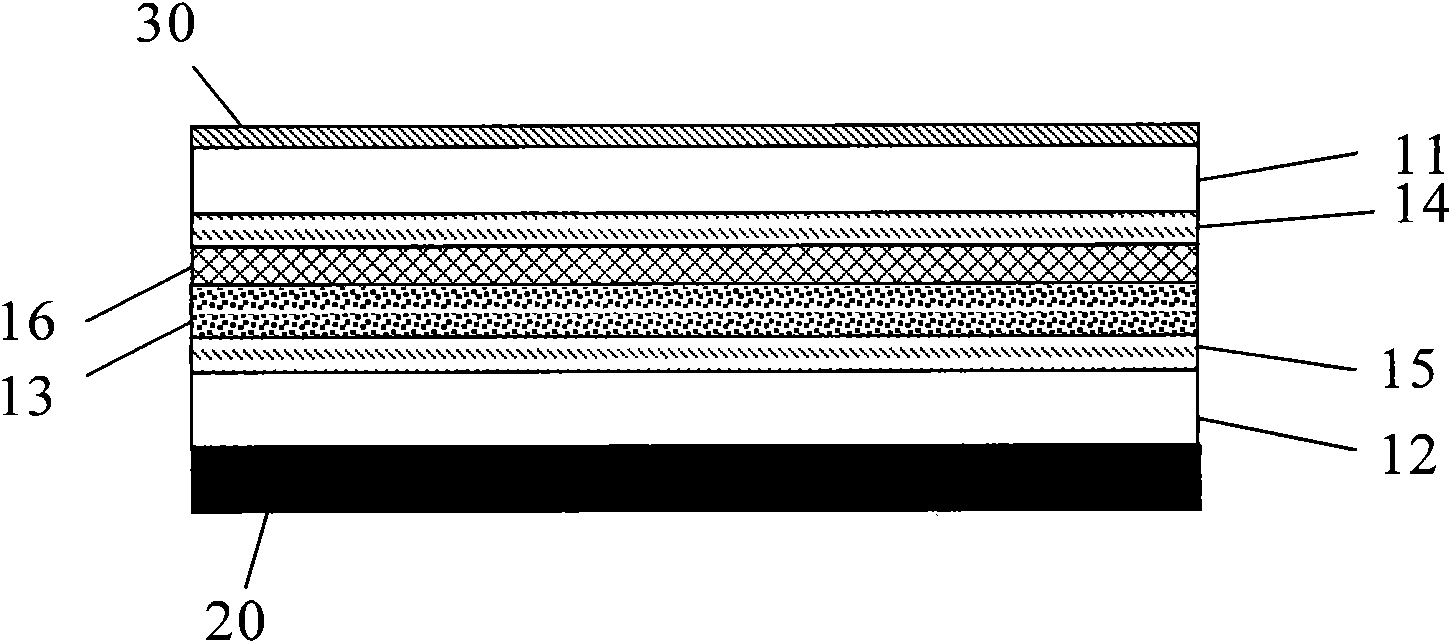

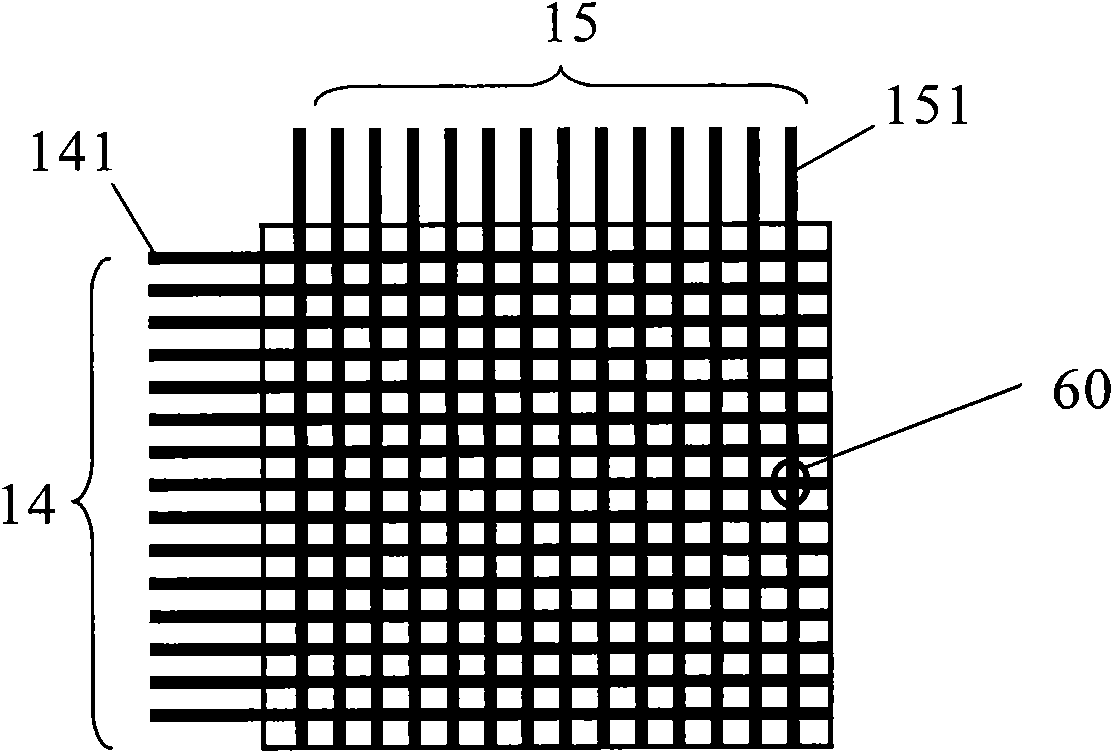

[0019] Such as Figure 1 to Figure 2 As shown, the smectic liquid crystal dyeing color display of the present invention includes a first base layer 11 and a second base layer 12, and the materials of the first base layer 11 and the second base layer 12 can be glass or plastic. Wherein, plastics can be transparent plastic film, also can be transparent hard plastic plate, be provided with mixed layer 13 between this first matrix layer 11 and this second matrix layer 12, this mixed layer 13 is made of smectic liquid crystal, additive , dichroic dyes, the first base layer 11 is provided with a first conductive electrode layer 14 on the side facing the mixed layer 13, and the second base layer 12 is provided with a second conductive electrode layer 12 facing the mixed layer 13. The conductive electrode layer 15, the first conductive electrode layer 14 and the second conductive electrode layer 15 are connected to an external drive control device (not shown in the figure), the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com