Patterning device for generating a pattern in and/or on a layer

A technology of equipment and composition, applied in welding equipment, opto-mechanical equipment, laser welding equipment, etc., can solve the problem of pattern taking too long, and achieve the effect of reducing composition time, increasing cost and reducing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

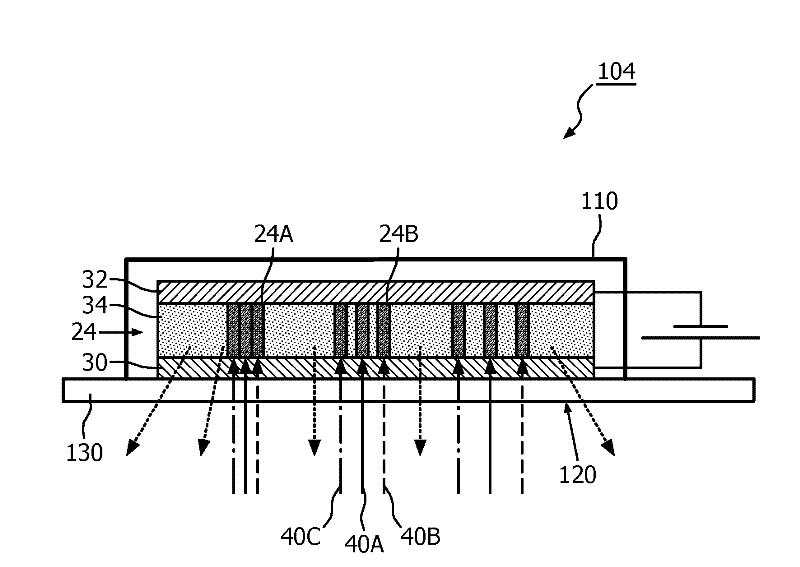

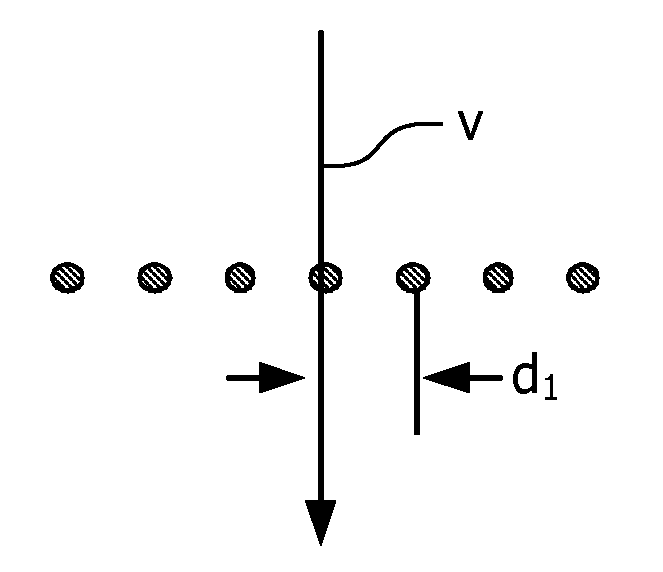

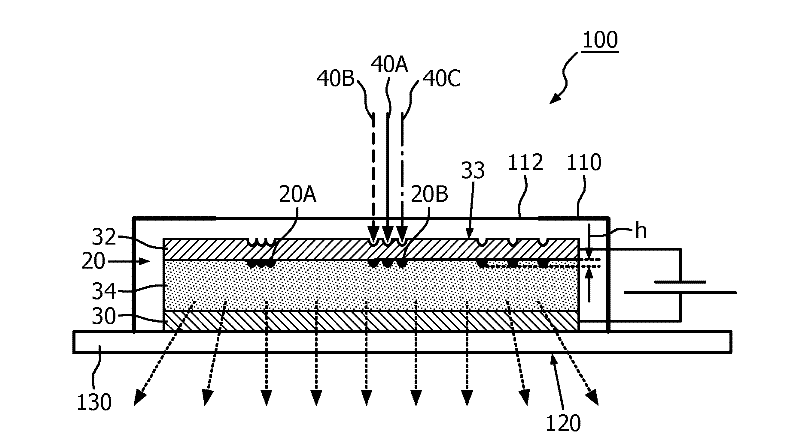

[0044] figure 1 A schematic cross-sectional view of a patterning device 10 according to the invention is shown for producing patterns 20 , 22 , 24 (see FIGS. 4 and 5 ) in and / or on layers 32 , 34 (see FIGS. 4 and 6 ). The patterning apparatus 10 comprises a light source 50 for generating a converging light beam 40 and comprises scanning means 70, eg a movable mirror 70 or a movable exposure chuck 72 on which a substrate comprising layers 32, 34 may be arranged. The patterning device 10 also comprises a diffractive optical element 60 for splitting the concentrated light beam 40 into a plurality of converging beamlets 40A, 40B, 40C. Via a diffractive optical element 60 , the single converging beam 40 is split into a plurality of converging beamlets 40A, 40B, 40C, so that the multiple converging beamlets can be used to generate the patterns 20 , 22 , 24 . In this way, especially when a relatively large area of the pattern 20, 22, 24 comprising areas of substantially equal gray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com