Automatic detaching machine for abandoned electronic circuit board element

A technology for electronic circuit boards and components, which is applied in the field of automatic dissociation machines for waste electronic circuit board components, can solve the problems of cumbersome operation, small processing capacity, and quick scraper damage, and achieve good working environment, strong adaptability, and low labor costs. low intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

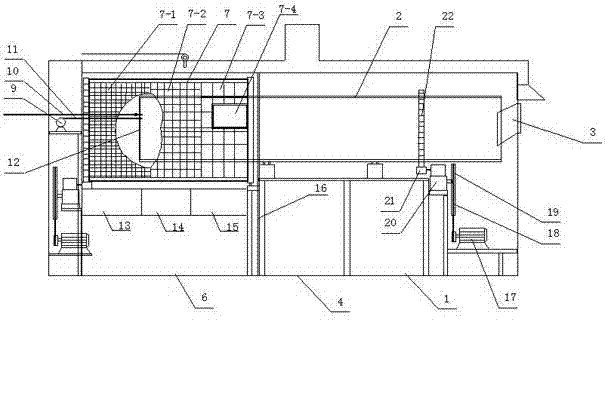

[0020] Such as figure 1 As shown, it is an automatic dissociation machine for waste electronic circuit board components, which includes a horizontal rectangular shell 4 composed of a steel frame lined with thermal insulation cotton. The shell is divided into a feed area 1 and a thermal dissociation area 6 by a partition 16 , the front end of the housing 4 is provided with a feeding port 3, and the rotary furnace 2 and the rotary screen 7 are respectively arranged in the horizontal direction in the housing 4 according to the front and rear order. The front end of the rotary furnace 2 is higher than the rear end, and the inclination angle is 3°. The rear end is higher than the front end with an inclination of 5°. The rotary furnace 2 is arranged on the rear side of the feeding port 3, the rotary screen 7 is set outside the rotary furnace 2, the front end of the rotary furnace 2 is arranged on the front side of the rotary screen 7, and the rear end of the rotary furnace 2 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com