Automatic cutting separator for waste CRT (cathode ray tube) display

A CRT display and automatic cutting technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of low efficiency, long operation time, high cost of wastewater treatment, etc., and achieve simple and flexible operation, low labor intensity, and easy treatment fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

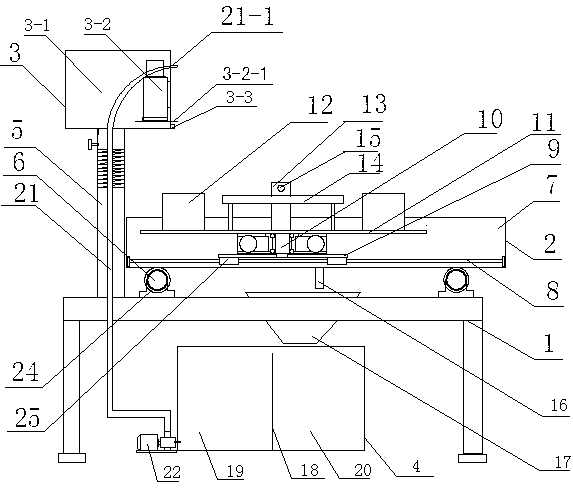

[0022] Such as figure 1 As shown, the present invention comprises support 1, cutting table 2, cutting machine 3, circulating water tank 4, and cutting table 2 is arranged on support 1 top, and cutting machine 3 is connected to the side of cutting table 2 by screw rod 5 and support 1, and circulating water tank 4 is arranged below the support 1.

[0023] Two long slides 6 parallel to each other are fixedly connected above the support 1; the cutting table 2 includes a water tank 7, and the water tank 7 is arranged above the two long slides 6 through the first sliding sleeve 24 fixed below the water tank 7.

[0024] Two short slides 8 parallel to each other are arranged in the water tank 7 and fixed on the bottom of the water tank 7; the two short slides 8 are perpendicular to the two long slides 6 respectively.

[0025] On the two short slideways 8, the second sliding sleeve 25 is connected with the cutting table base 9, and the rotating table 11 is connected with the bearing 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com