How to assemble the lateral control arm

A technology of assembly position and fastening device, which is applied in the direction of manufacturing tools, transportation and packaging, cantilevers mounted on pivots, etc., and can solve problems such as deformation of axle geometry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

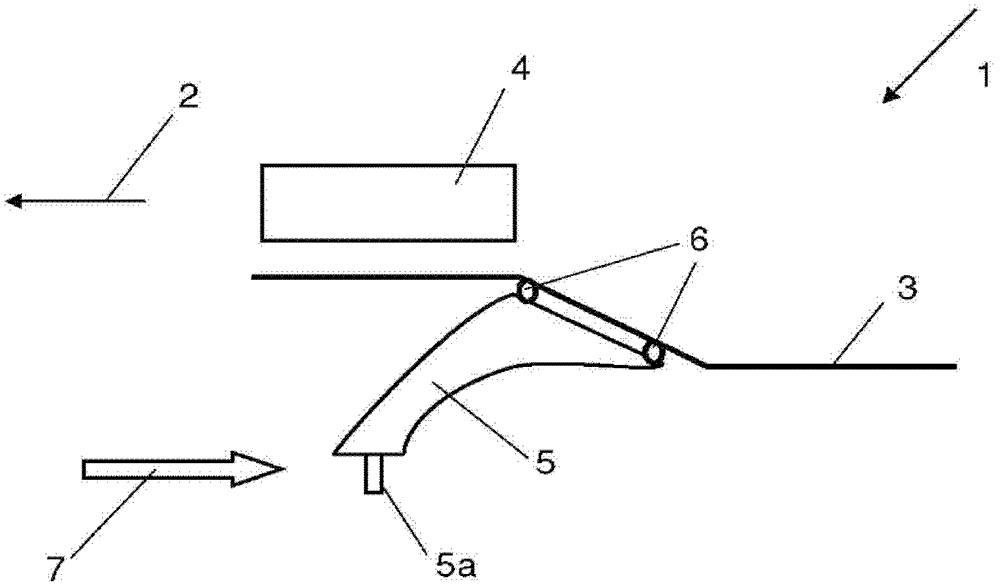

[0017] The sole figure shows a schematic diagram of a part of a motor vehicle. The figures show parts of a vehicle longitudinal part 3 and an engine 4 . The direction of travel of motor vehicle 1 is indicated by arrow 2 . The A-arm 5 and the wheel journal 5 a are connected to the longitudinal part 3 via two assembly points 6 . According to the invention, a force in the direction of the arrow 7 is exerted on the A arm 5 and the associated fastening element is moved into its rearmost position relative to the mounting point 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com