Tire tread color line ruling device

A tire tread and color line technology, which is applied in the field of tire manufacturing equipment, can solve the problems of uncontrollable glue flow and easy blockage of the marking needle tube, etc., and achieve the goals of saving glue consumption, smooth marking, and high marking quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

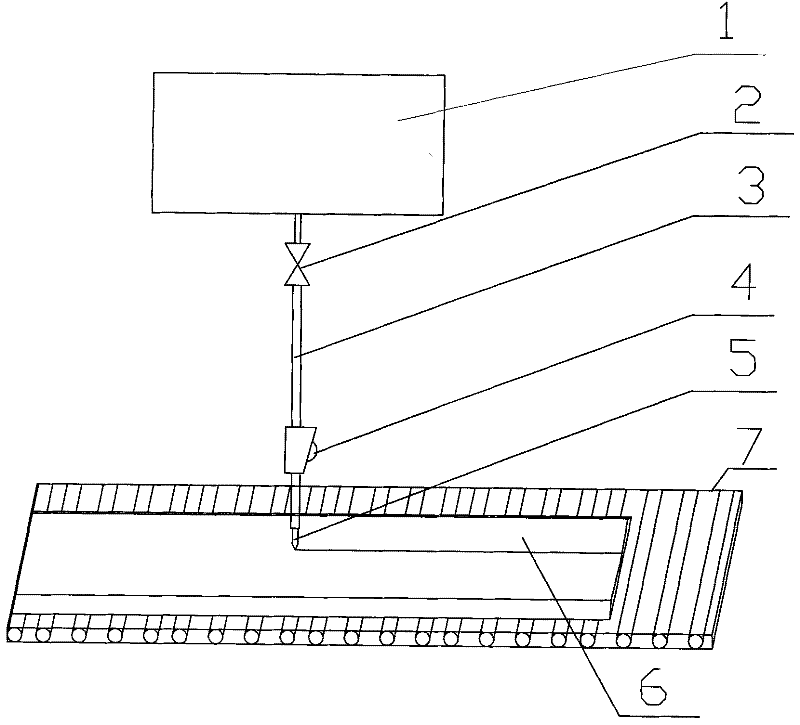

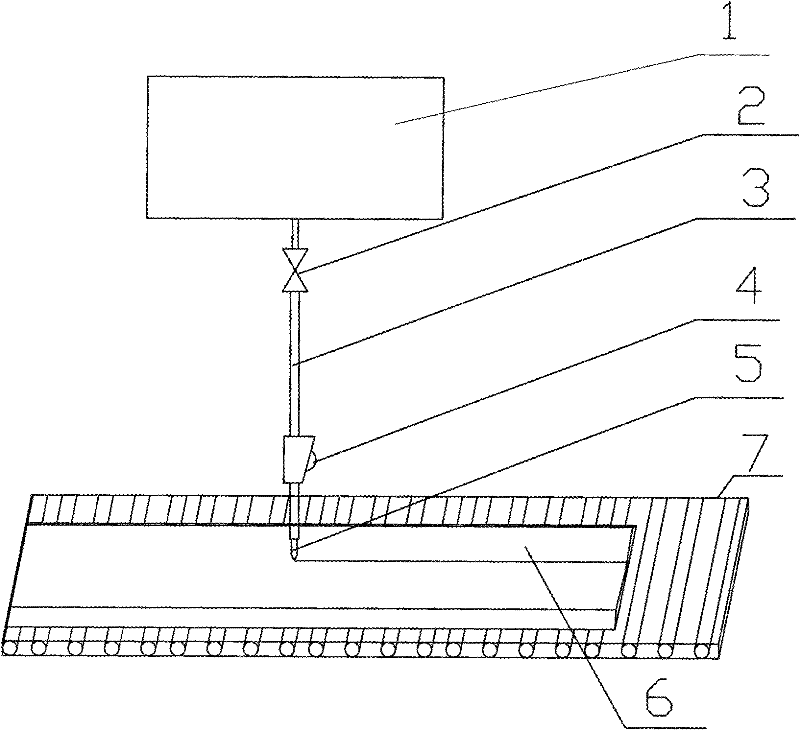

[0009] As shown in the figure, a tire tread color line marking device is mainly composed of a glue box 1, a glue tube 3 and a marking needle 5. The glue tube 3 is connected to the glue box for marking. The needle 5 is fitted to the end of the glue tube.

[0010] The glue pipe 3 is provided with a shut-off valve 2 for controlling the flow of glue. The stop valve 2 uses a conventional straight-through stop valve.

[0011] The glue pipe 3 is also provided with a flow control valve 4 for controlling the flow of glue. The wheel pressure type flow control valve adopted by the flow control valve 4 has the same structure as the flow control valve used on the infusion set.

[0012] The marking needle 5 adopts an air needle with an inner diameter of 1 mm. Because the inside of the tube head of the air needle is thin, the air return flow is small, the gasoline volatilization speed in the glue is slow, the glue is not easy to agglomerate, and the pipeline is not easy to block.

[0013] As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com