Release material and preparation method thereof

A release material and substrate layer technology, which is applied in the field of release film materials and its preparation, can solve problems such as unstable product performance, strong randomness of cracks, and differences in the release force of cracked parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

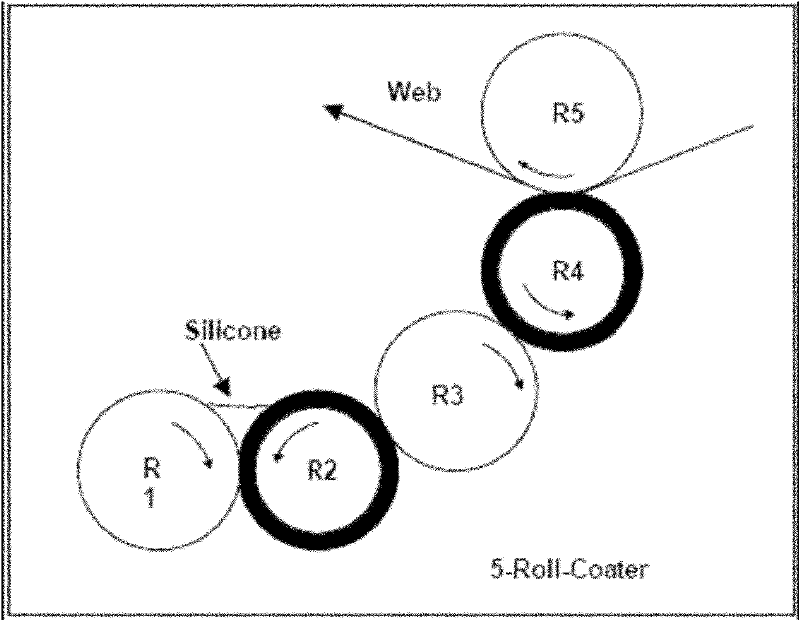

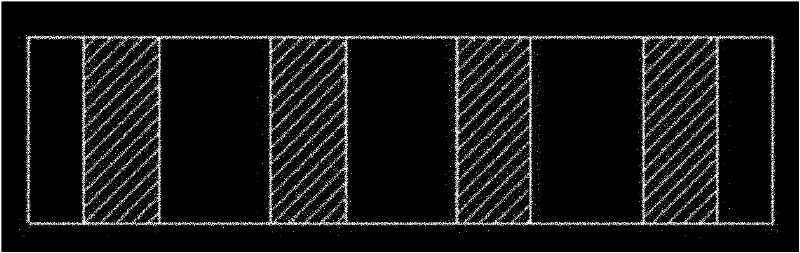

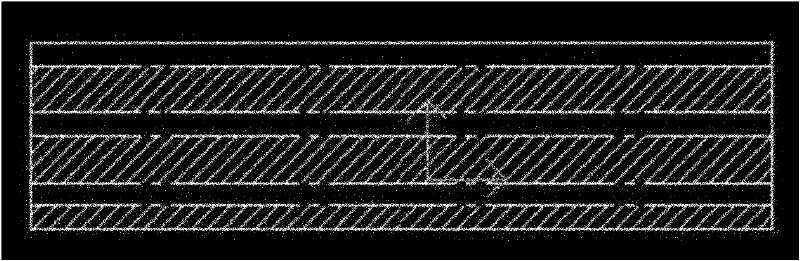

[0097] After unwinding the PE film, it will be corona coated by a five-roll coater. The specific parameters: the surface density of the PE film is 25g / m 2 , The unwinding speed is 80m / min, the surface tension after corona is 45mN / m (dyne), the interval coating width is 40mm, and the coating weight per square meter is 0.4g / m 2 , Under the condition of UV light intensity of 1300m / min, the release material is formed, the peeling force at the place where the silicone oil is coated in the release material can reach 12 g / 25mm, and the residual adhesion rate can reach 84%.

Embodiment 2

[0099] After the PE film is unrolled, it will be corona coated by a five-roll coater. The specific parameters: the surface density of the PE film is 30g / m 2 , The unwinding speed is 120m / min, the surface tension after corona is 40mN / m (dyne), the interval coating width is 35mm, and the coating weight per square meter is 0.28g / m 2 , Under the condition of UV light intensity of 1500m / min, the release material is formed, the peeling force of the release material where the silicone oil is coated can reach 15 g / 25mm, and the residual adhesion rate can reach 90%.

Embodiment 3

[0101] After unwinding the BOPP film, it will be corona coated by a five-roll coater. The specific parameters: BOPP film surface density is 25g / m 2 , The unwinding speed is 150m / min, the surface tension after corona is 40mN / m (dyne), the interval coating width is 60mm, and the coating weight per square meter is 0.35g / m 2 , Uv light intensity is 2000m / min into the release material, the release material is coated with silicone oil, the peeling force can reach 24 g / 25mm, and the residual adhesion rate can reach 87%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com