Overcurrent or continuous current-carrying self-protection tab and manufacturing method thereof

A protection type, tab technology, applied in the field of lithium-ion batteries, can solve problems such as high current overcharge and discharge, thermal runaway, short circuit, etc., to prevent thermal runaway, prevent fire or explosion, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0044] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

Embodiment 1

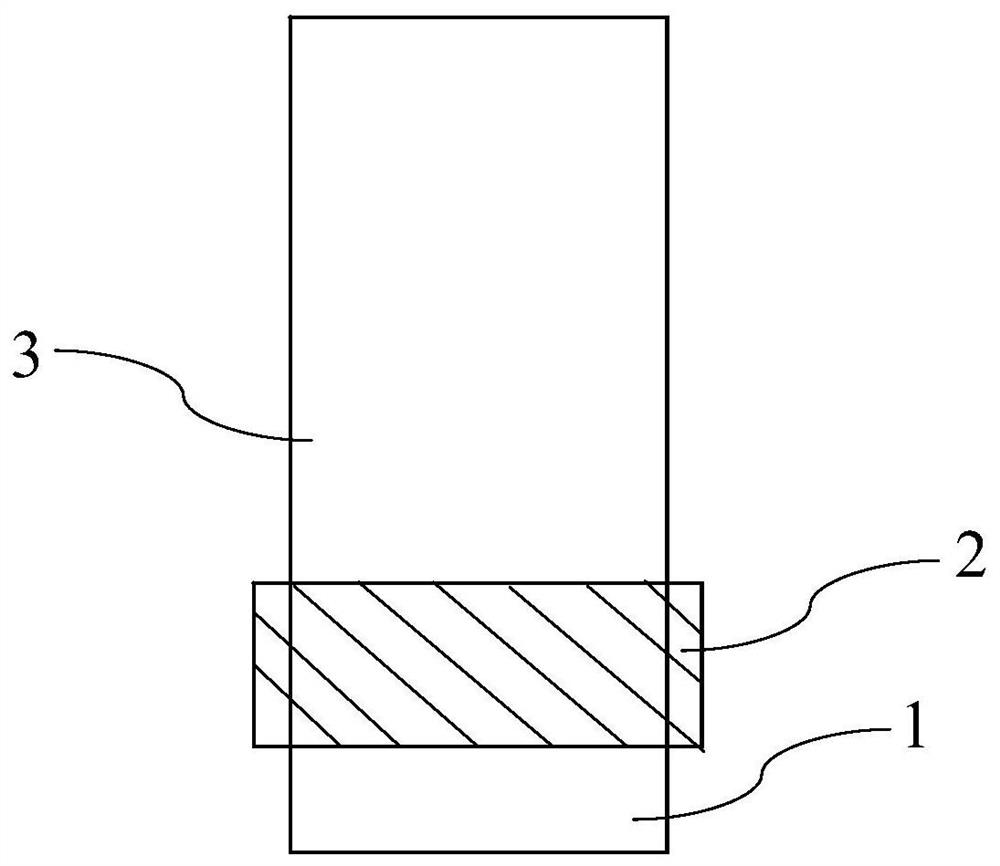

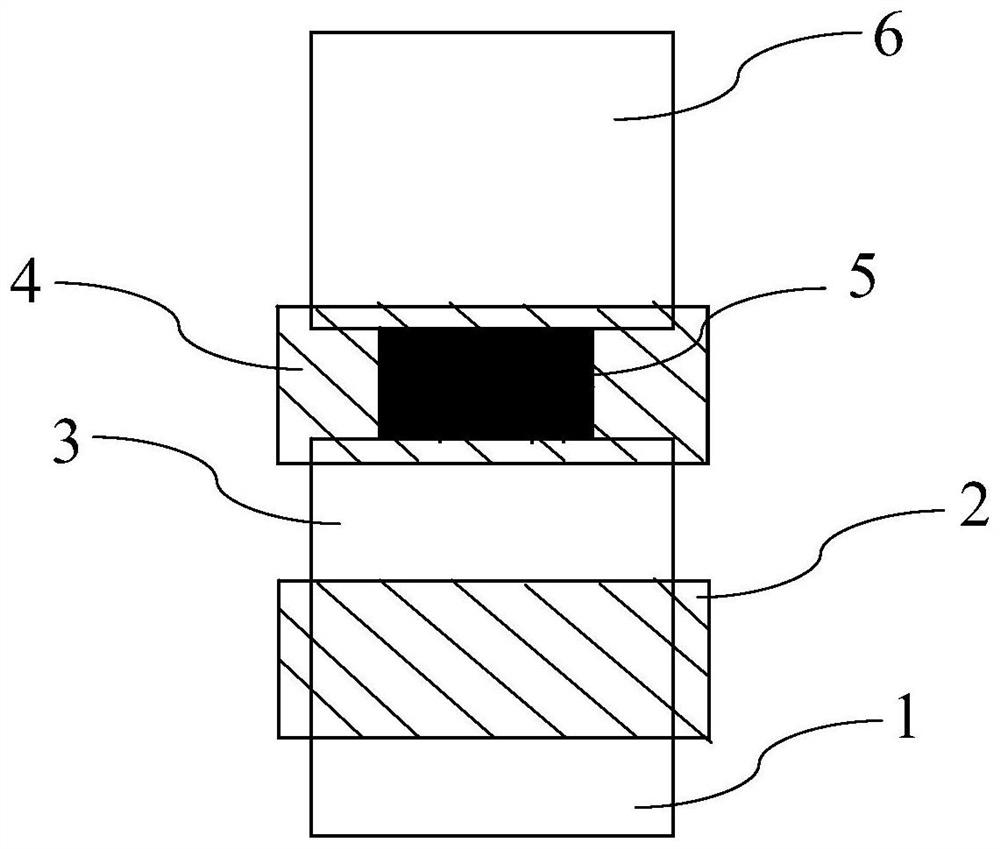

[0046] Such as image 3 Shown in this example is an overcurrent self-protective tab for a lithium-ion battery. The upper and lower sides of the negative nickel tab sheet with a size of 0.1 mm thick and 6 mm wide are heat-sealed and bonded to polypropylene by high-frequency welding. Ear glue, the total thickness of the ear glue is 0.16mm, the width is 3.5mm, and the length is 10mm. The ear glue divides the negative nickel tab sheet into a protruding end and a welding end; The PTC thermistor (0.08mm thick*3mm wide*4mm long) is welded by ultrasonic welding between the output end and the PACK assembly end (the material is nickel sheet, the size is 0.1mm thick*6mm wide), and the temperature trigger point: 65 ℃); heat-seal and bond a layer of polypropylene protective glue on the surface of the PTC thermistor by hot-pressing. The size of the protective glue is 0.1mm thick*6mm wide*10mm long. Conventional aluminum lugs in the prior art (dimensions: 0.1mm thick*6mm wide).

[0047] The ...

Embodiment 2

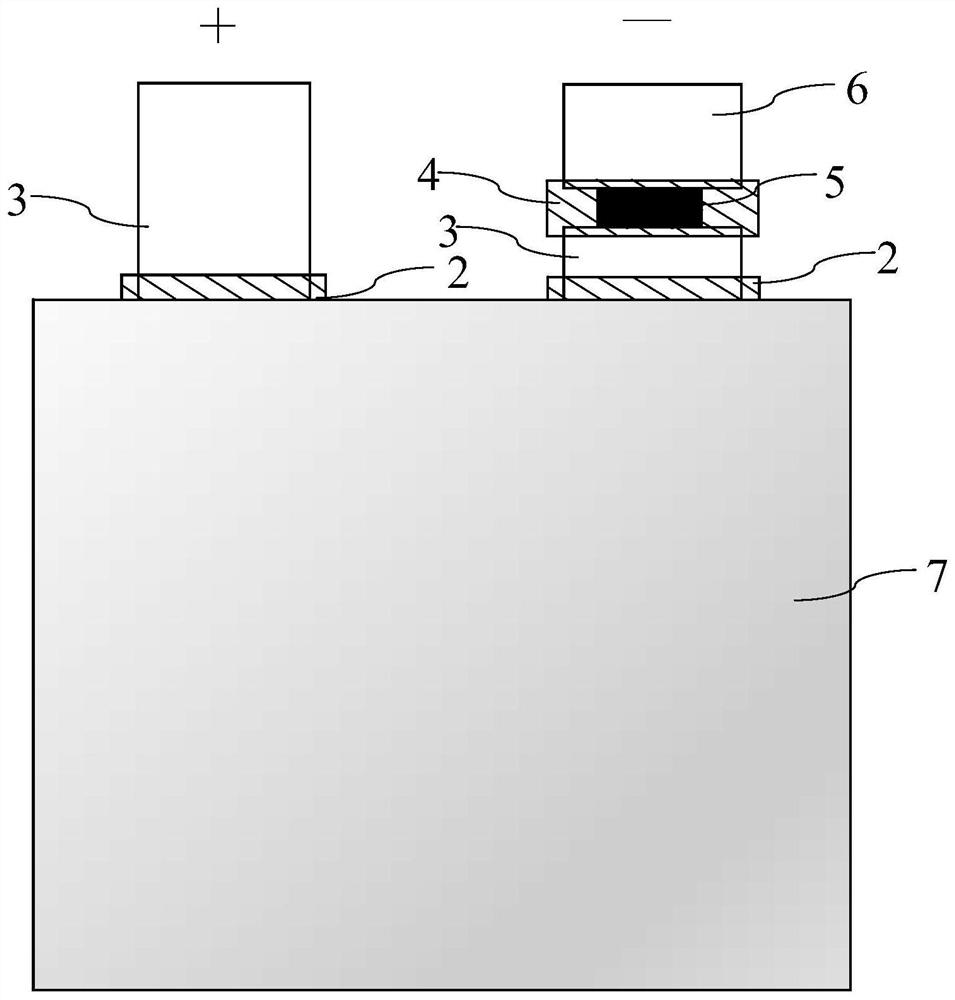

[0050] Such as Figure 4 Shown is another implementation diagram of the lithium-ion battery overcurrent self-protection tab of the present invention. The positive electrode is an aluminum tab sheet (size: 0.15mm thick*5mm wide), which is bonded to the polypropylene pole by hot pressing. Ear glue, the aluminum tab sheet is divided into a welding end and a protruding end, wherein the protruding end is connected to the PTC thermistor by laser welding (the size of the PTC thermistor is: 0.15mm thick*3mm wide*3mm long, temperature Trigger point: 90°C), the other end of the PTC thermistor is connected by laser welding and PACK assembly end (size: 0.12mm thick * 5mm wide), and the upper and lower surfaces of the PTC thermistor are bonded by hot pressing Covered with polyethylene protective glue (size: 0.2mm total thickness*7mm width*10mm length), the negative electrode of this embodiment uses a nickel-plated copper tab with a thickness of 0.15mm*5mm width.

[0051] The overcurrent s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com