Completely degradable kraft paper buffer air cushion and preparation method thereof

A technology of kraft paper and air cushion, which is applied in the direction of sustainable manufacturing/processing, packaging paper, climate sustainability, etc. It can solve the problems of inflated saturation and compression resistance, poor folding and curling performance, and low inflating efficiency, etc., to achieve Improve the cushioning effect of the package, reduce the difficulty of inflation, and improve the production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The second aspect of the present application provides the preparation method of the fully degradable kraft paper cushion air cushion as described above, which includes the following steps:

[0043] (1) The POE material containing 30% 1500 mesh calcium carbonate is used to flush the screw;

[0044] (2) Place the kraft paper roll on the machine frame, pull it to the casting die of the laminating machine through the traction wheel, and heat the traction roller, casting die and screw;

[0045] (3) Add the raw materials for the preparation of the inner layer into the coating machine, and coat the surface of the kraft paper on the frame of the machine, then press the cooling roller, cut and roll to obtain the air cushion film;

[0046] (4) Place two layers of the air-cushion film on the unwinding rack in such a way that the coated surfaces of the air-cushion film face each other, and heat the mold of the machine, and then heat-seal the interlayer air-cushion film.

[0047] D...

Embodiment 1

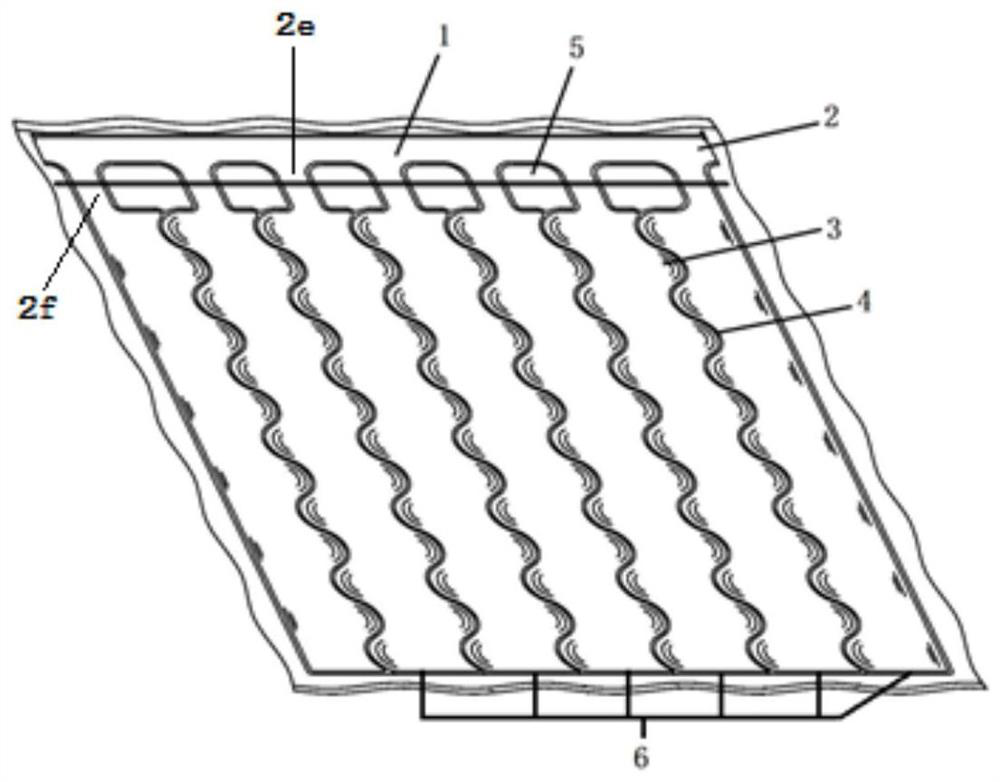

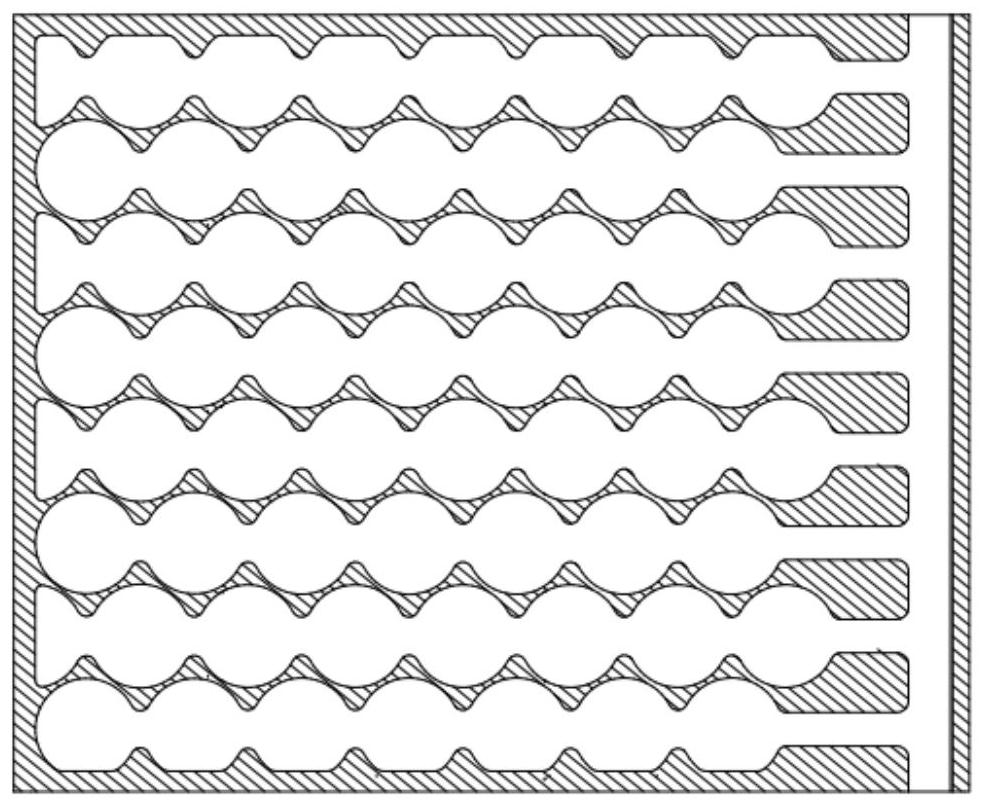

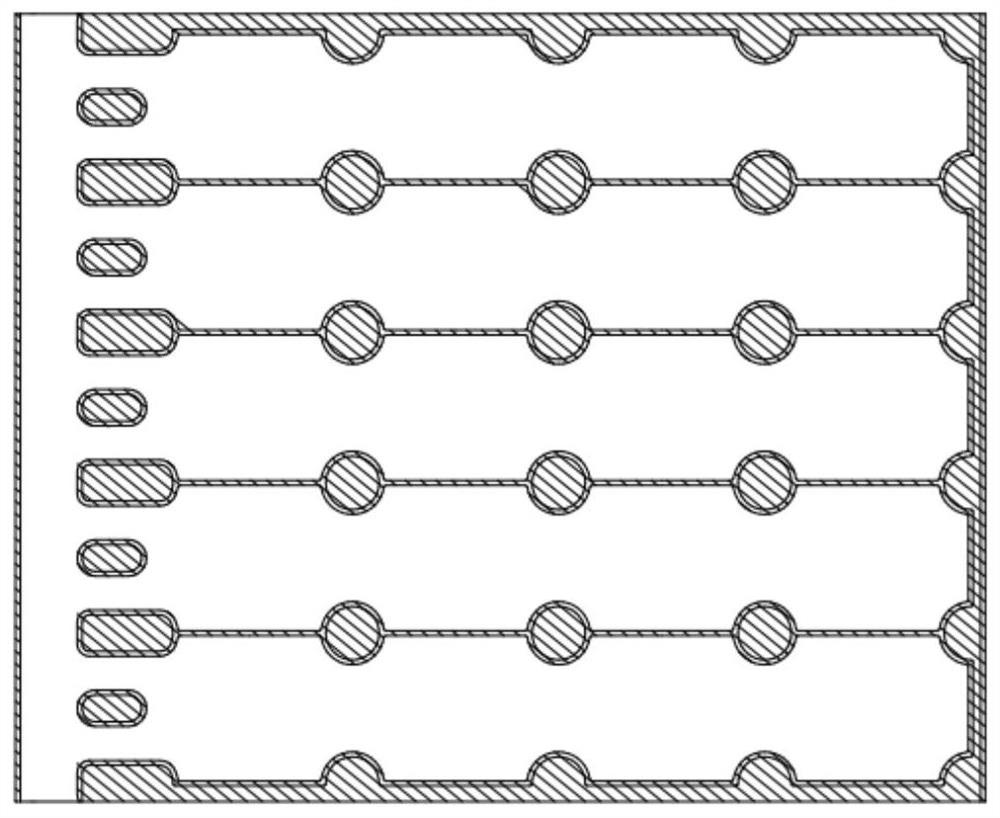

[0054] Example 1 : see figure 1 , this embodiment provides a fully degradable kraft paper cushioning air cushion, which includes several air storage units 6 and air supply channels 1 formed by heat sealing two layers of air cushion films; the air supply channels 1 are provided with inflation ports 2; The top of the gas storage unit is provided with a heat seal ring 5, and an air inlet 2e is formed between two adjacent heat seal rings 5, and the air supply channel 1 and the gas storage unit 6 are connected through the air inlet 2e. connection; the gas storage unit 6 is composed of several gas storage chambers 3, and the several gas storage chambers 3 are connected by an air neck 4; the gas storage chamber 3 has an S-shaped structure; the size of the air neck 4 50mm; the heat seal ring 5 extends in the longitudinal direction to form a gas channel 2f; the width of the gas channel inlet 2e is 2cm.

[0055]The above-mentioned fully degradable kraft paper cushion air cushion is ...

Embodiment 2

[0078] This comparative example provides a cushioning air cushion, which includes several air storage units 6 and air supply channels 1 formed by heat sealing two layers of air cushion films; the air supply channel 1 is provided with an inflation port 2; A heat seal ring 5 is arranged on the top, and an air inlet 2e is formed between two adjacent heat seal rings 5, and the air supply channel 1 and the air storage unit 6 are connected through the air inlet 2e; The air unit 6 is composed of several air storage chambers 3, which are connected by air necks 4; the air storage chambers 3 have an S-shaped structure; the size of the air necks 4 is 50mm; The heat seal ring 5 extends in the longitudinal direction to form a gas channel 2f; the width of the gas channel inlet 2e is 2 cm.

[0079] The above-mentioned fully degradable kraft paper cushion air cushion is made by laminating the fully degradable plastic and kraft paper material, including the outer layer and the inner layer; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com