Down fabric

A down fabric and down technology, applied in the field of down fabrics, can solve the problems of uneven thickness of inner liner down, decreased thermal insulation effect, and easy drilling of down, and achieve the effect of saving down consumption, low production cost and uniform thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

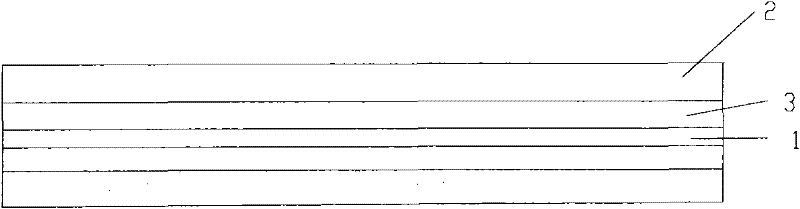

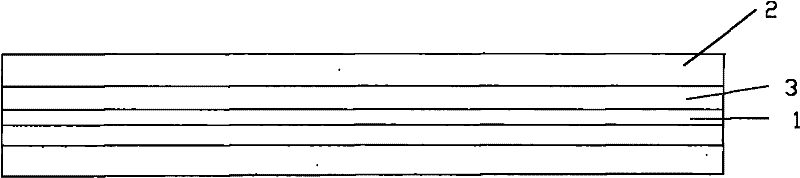

[0014] The present invention will now be described in further detail in conjunction with the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0015] see figure 1 , a down fabric, comprising a fabric layer 1 and a down layer 2, the fabric layer 1 adopts cotton, hemp, wool and chemical fiber woven or knitted fabrics. The upper and lower sides of the fabric layer 1 are respectively glued with polyurethane film glue 3, and the thickness is 0.05-0.3 centimeters. On the polyurethane film glue, a down layer 2 is set, and the down layer 2 contains the following components by weight percentage: down 60- 80%, chemical fiber 20-40%, down refers to one or more of goose down, duck down, velvet, chicken or bird down, chemical fiber is synthetic fiber, nylon, polyester, acrylic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com