Preparation method for inhomogeneous dielectric substrate

A non-uniform medium and substrate technology, which is applied in the field of manufacturing and processing of metamaterial substrates, can solve problems such as difficulty in meeting the electromagnetic properties of dielectric substrates, and achieve the effect of satisfying the requirements of electromagnetic properties and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

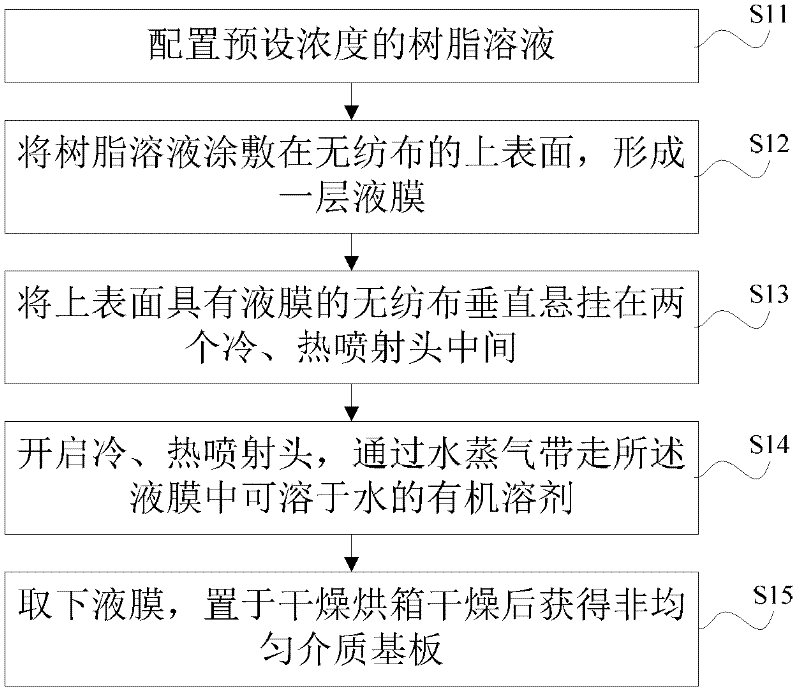

[0019] see figure 1 , is a flowchart of a method for preparing a heterogeneous dielectric substrate provided in Embodiment 1 of the present invention, and the method includes:

[0020] S11: configuring a resin solution with a preset concentration.

[0021] Wherein, the resin solution with the preset concentration is polysulfone (PSF / PSU) solution; or polyvinylidene fluoride (PVDF) solution. The concentration of the polysulfone solution is 15-20%; the concentration of the polyvinylidene fluoride solution is 20-25%.

[0022] S12: coating the resin solution on the upper surface of the non-woven fabric to form a layer of liquid film.

[0023] Wherein, the shape of the non-woven fabric is square or rectangular.

[0024] S13: Hang the non-woven fabric with the liquid film on the upper surface vertically between the two cold and hot spray heads.

[0025] S14: Turn on the cold and hot spray heads, and take away the water-soluble organic solvent in the liquid film through water vap...

Embodiment 2

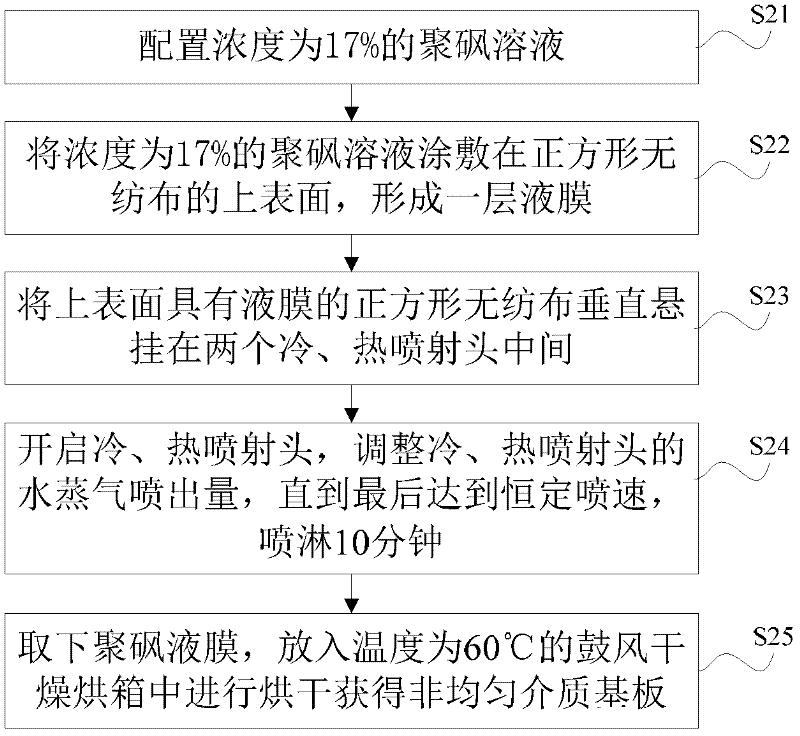

[0031] see figure 2 , is a flowchart of a method for preparing a heterogeneous dielectric substrate provided in Embodiment 2 of the present invention, and the method includes:

[0032] S21: Prepare a polysulfone solution with a concentration of 17%.

[0033] S22: Coating a polysulfone solution with a concentration of 17% on the upper surface of the square non-woven fabric to form a layer of liquid film.

[0034] S23: Hang the square non-woven fabric with the liquid film on the upper surface vertically between the two cold and hot spray heads.

[0035] S24: Turn on the cold and hot spray heads, adjust the water vapor ejection volumes of the cold and hot spray heads until a constant spray speed is finally reached, and spray for 10 minutes.

[0036] Wherein, the water vapor ejection amount of the cold spray head is greater than the water vapor ejection amount of the hot spray head.

[0037] S25: remove the polysulfone liquid film, put it into a forced air drying oven at a tem...

Embodiment 3

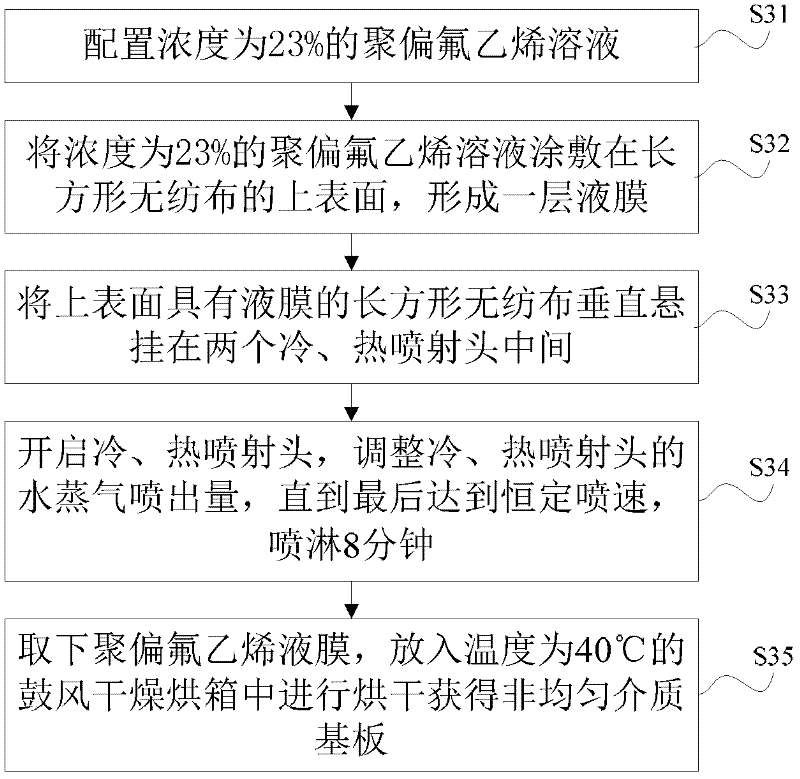

[0040] see image 3 , is a flow chart of a method for preparing a heterogeneous dielectric substrate provided in Embodiment 3 of the present invention, and the method includes:

[0041] S31: Prepare a polyvinylidene fluoride solution with a concentration of 23%.

[0042] S32: Coating a polyvinylidene fluoride solution with a concentration of 23% on the upper surface of the rectangular non-woven fabric to form a layer of liquid film.

[0043] S33: vertically hang the rectangular non-woven fabric with the liquid film on the upper surface between the two cold and hot spray heads.

[0044] S34: Turn on the cold and hot spray heads, adjust the water vapor spraying volume of the cold and hot spray heads until a constant spray speed is finally reached, and spray for 8 minutes. During this process, the water vapor carried away the water-soluble organic solvent in the liquid film.

[0045] Wherein, the water vapor ejection amount of the cold spray head is greater than the water vapo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com