New Metamaterials and Their Fabrication Process

A manufacturing process and metamaterial technology, applied in the field of metamaterials, can solve the problems of high dielectric constant, signal attenuation, and the inability to use brittle dielectric substrates, etc., and achieve the effect of simple manufacturing process and firm combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

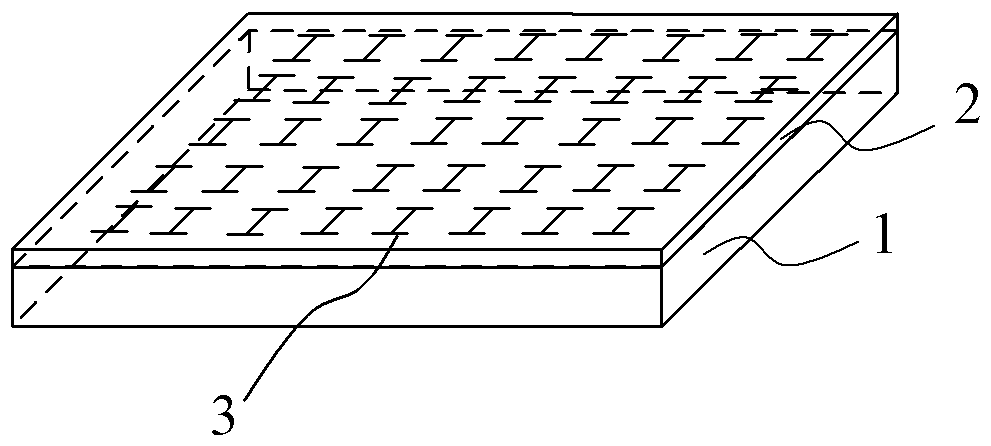

[0022] see figure 1 , the present invention relates to a novel metamaterial, which includes a material sheet, the material sheet includes a dielectric substrate 1, a photosensitive composite layer 2 and a metal layer, and the dielectric substrate 1 can be made of a high molecular polymer material, Made of ceramic material, polytetrafluoroethylene material, ferroelectric material, ferrite material, or ferromagnetic material. In this embodiment, the dielectric substrate 1 is made of materials other than glass fiber epoxy resin, such as polytetrafluoroethylene, so that a lower dielectric constant (ε) and dielectric loss tangent (Tanδ) can be obtained , so as not to cause the problem of signal attenuation when the electromagnetic wave passes through the metamaterial made of the dielectric substrate.

[0023] The photosensitive composite layer 2 is located between the dielectric substrate 1 and the metal layer, and the metal layer is fixed on the dielectric substrate 1 through the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com