Fabrication Process of Metamaterials

A preparation process and metamaterial technology, applied in the field of metamaterial preparation technology, can solve the problems of reducing the selectivity of metamaterial substrates, unable to use brittle substrates, high dielectric constant, etc., and achieve mass production and waste products. The effect of low rate, easy operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

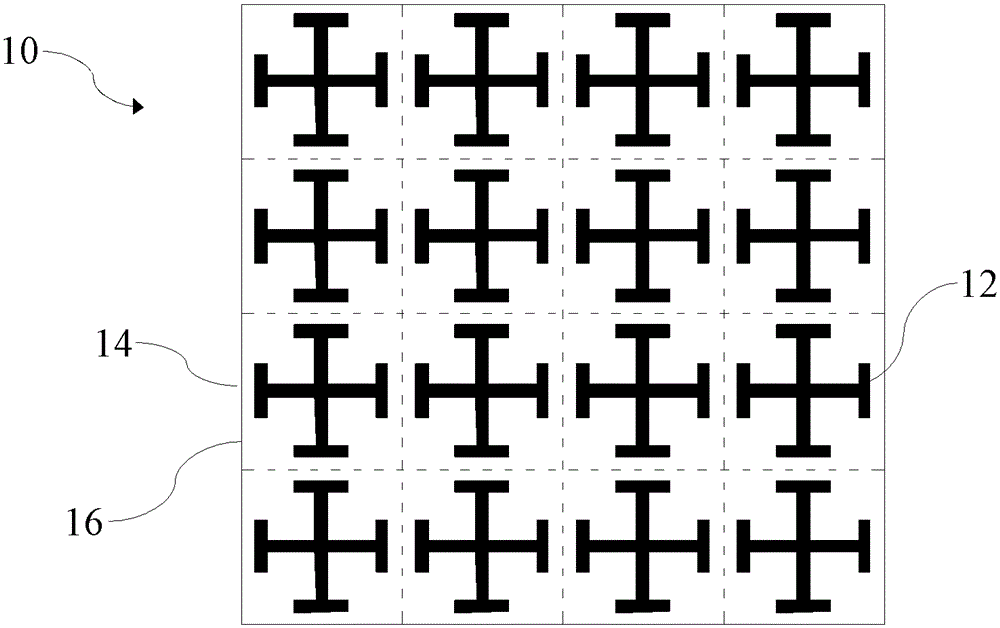

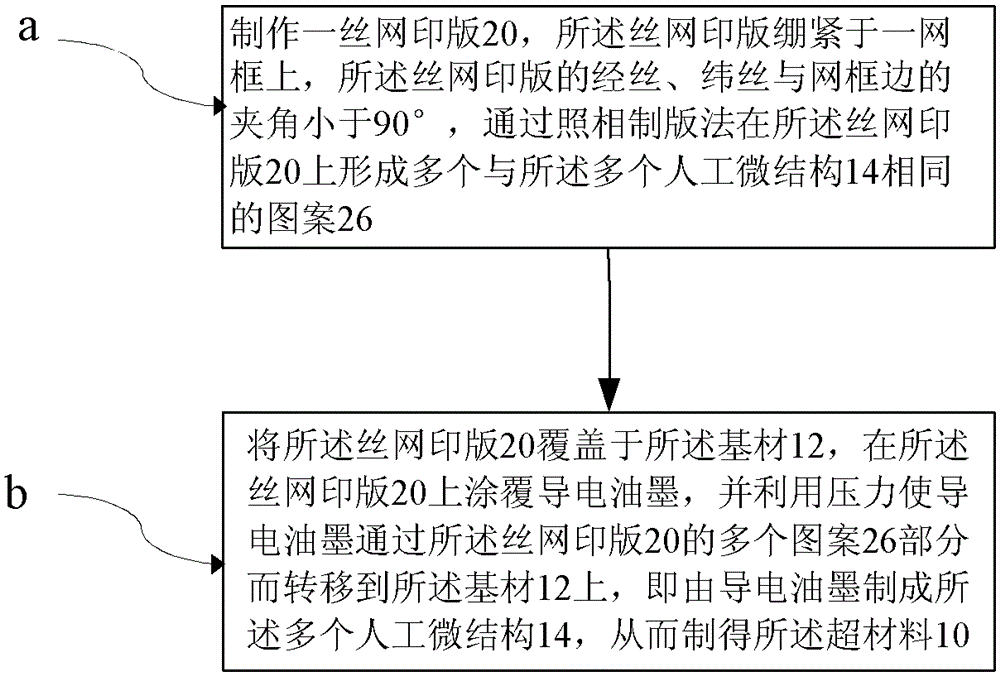

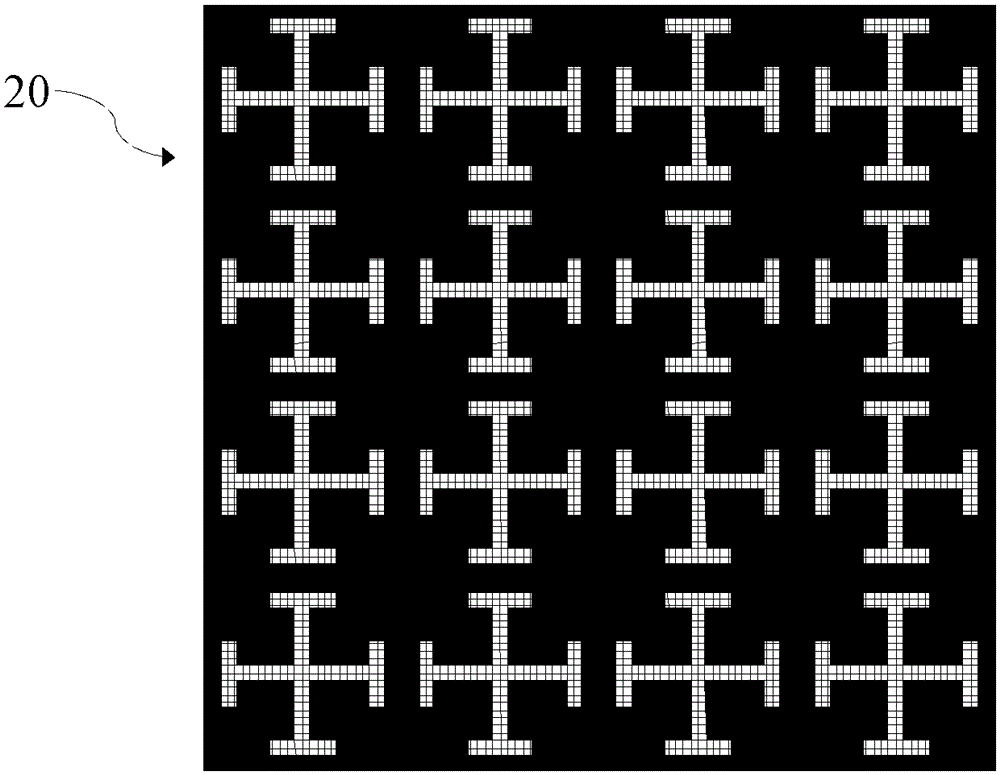

[0027] Such as figure 1 As shown, the fabrication process of the metamaterial of the present invention is used to form a plurality of artificial microstructures 14 on a substrate 12 to produce the metamaterial 10 . The substrate 12 is made of materials such as ceramics or polymers, and each artificial microstructure 14 is a planar or three-dimensional structure with a certain geometric shape composed of metal wires such as copper wires or silver wires. If each artificial microstructure 14 and the part of the substrate 12 where it is located is artificially defined as a metamaterial unit 16, then the metamaterial 10 can be regarded as being formed by an array of these metamaterial units 16, and these artificial The microstructures 14 are periodically arranged on the substrate 12 . That is, the metamaterial 10 includes the substrate 12 and a plurality of artificial microstructures 14 periodically arranged on the substrate 12 . Generally, the geometric size of each metamaterial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com