Copper foil composite

A composite, copper foil technology, used in the manufacture of printed circuit precursors, electronic equipment, printed circuits, etc., can solve problems such as poor electromagnetic wave shielding, and achieve the effect of improving processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

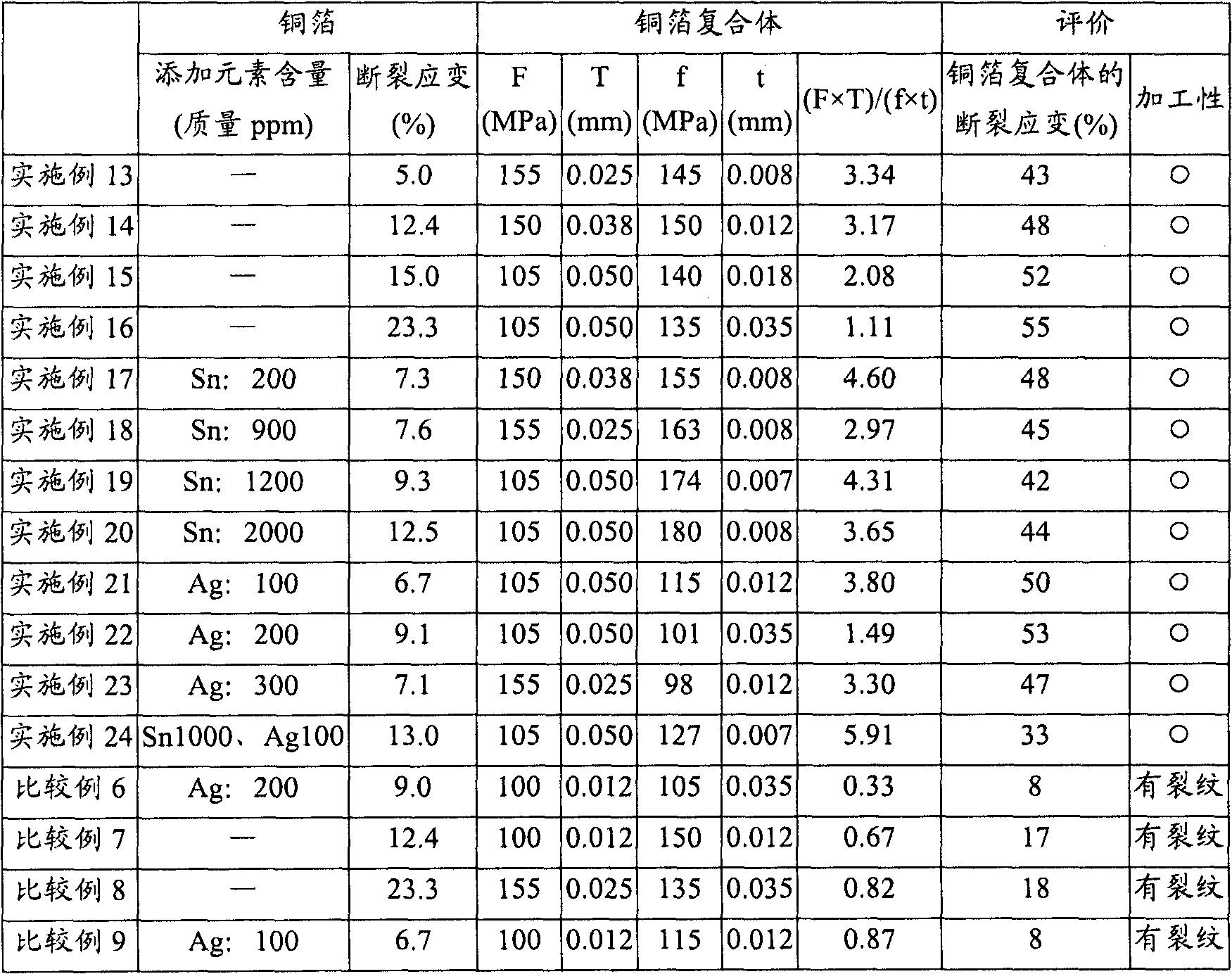

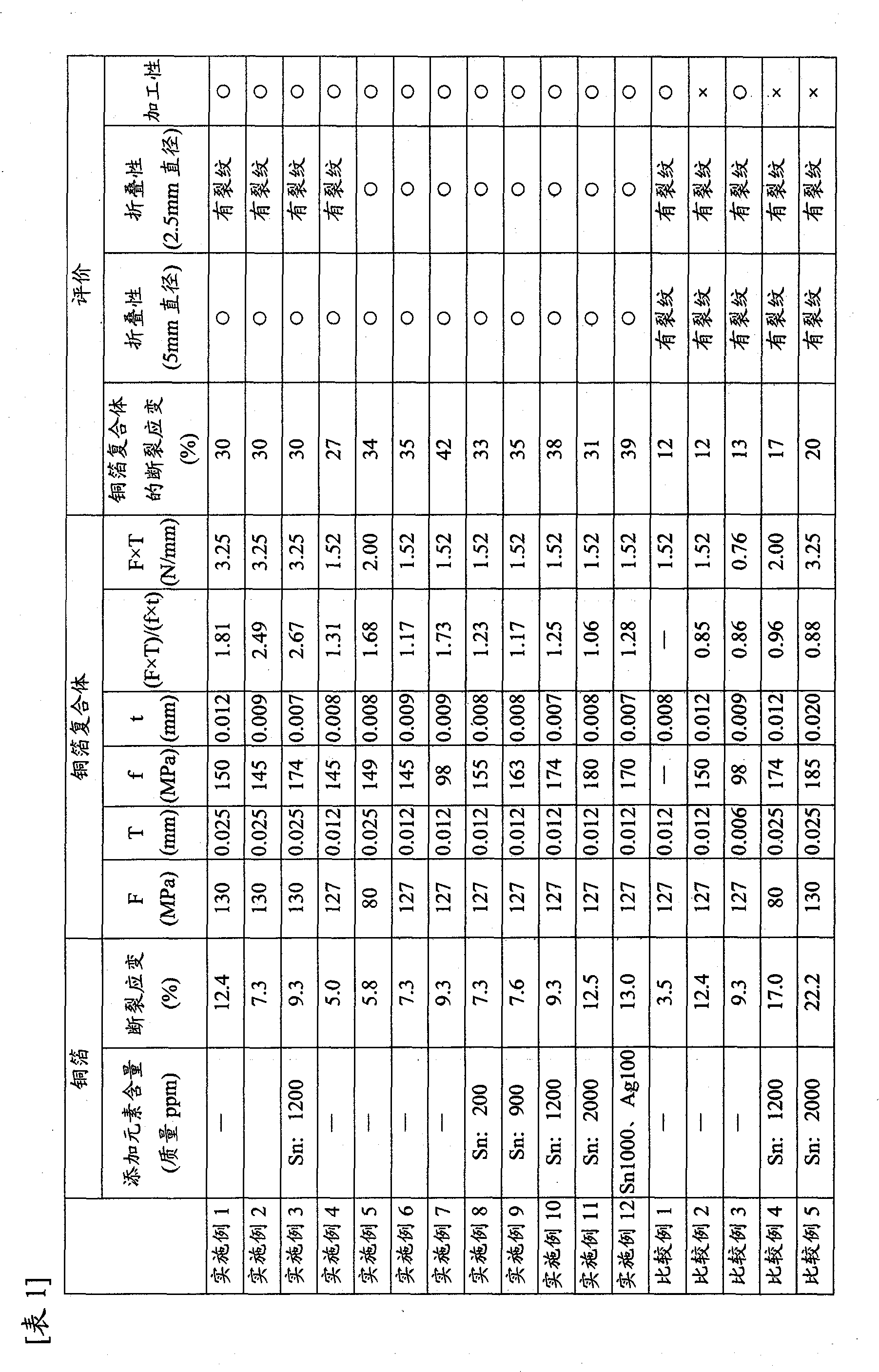

Examples

Embodiment

[0048] 1. Electromagnetic wave shielding material

[0049]

[0050] Tough copper ingots are hot-rolled, and after surface cutting to remove oxides, cold-rolling, annealing and pickling are repeated to make it thinner to a specified thickness, and finally annealing is performed to obtain workability-guaranteed copper foil. The tension during cold rolling and the rolling conditions (reduction conditions) in the width direction of the rolled material are kept uniform so that the copper foil has a uniform structure in the width direction. In the subsequent annealing, the temperature was controlled using a plurality of heaters, and the temperature of copper was measured and controlled so as to form a uniform temperature distribution in the width direction. Copper foil is produced by adding a predetermined amount of Sn or Ag to several copper ingots.

[0051] A commercially available biaxially stretched PET film of a predetermined thickness was bonded to the above-mentioned copp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com