System for control of a gearbox

一种变速箱、控制单元的技术,应用在传动装置控制、带有齿的元件、皮带/链条/齿轮等方向,能够解决少利驱动状况、校准程序费时间、费用高昂等问题,达到改良操纵灵活性感觉的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

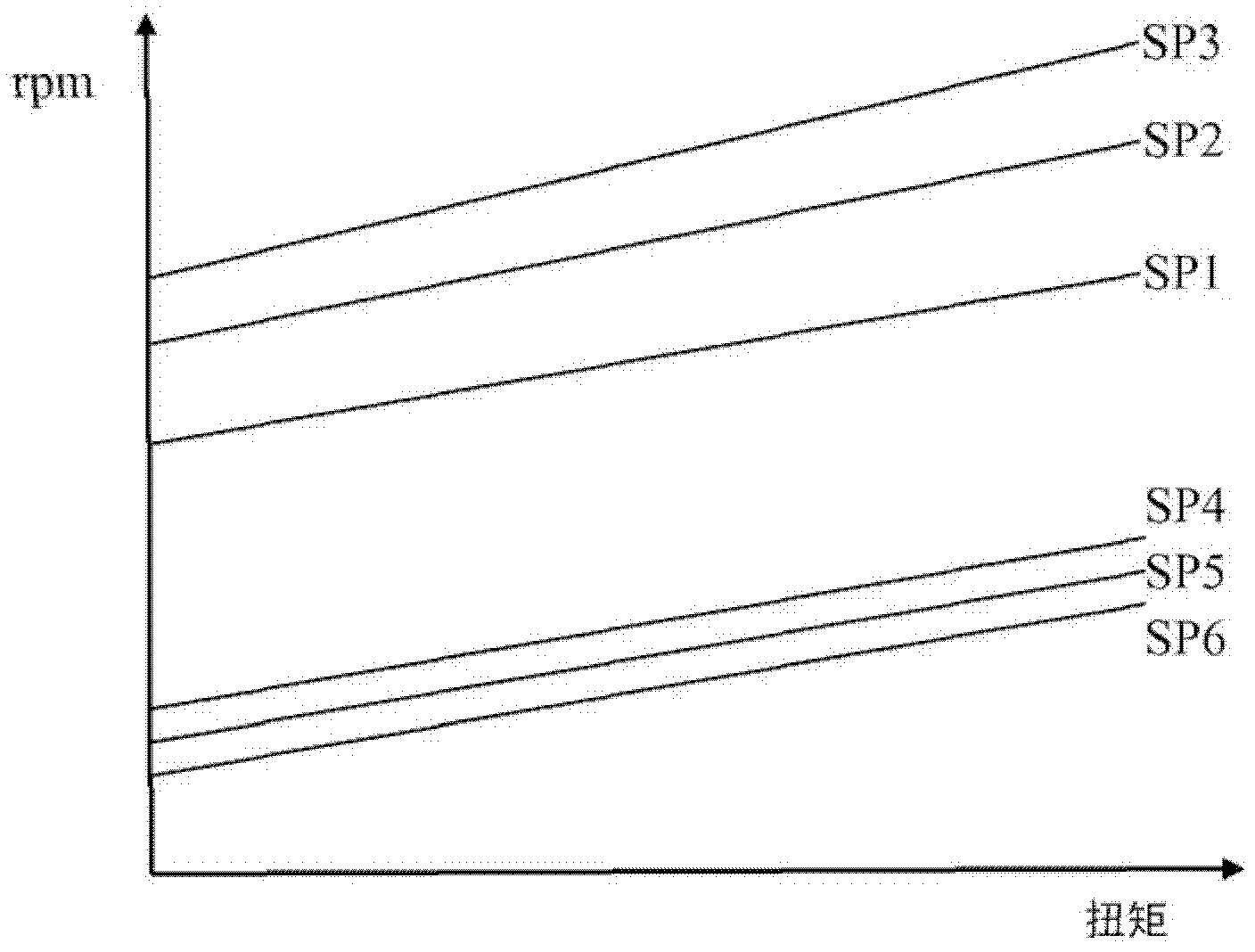

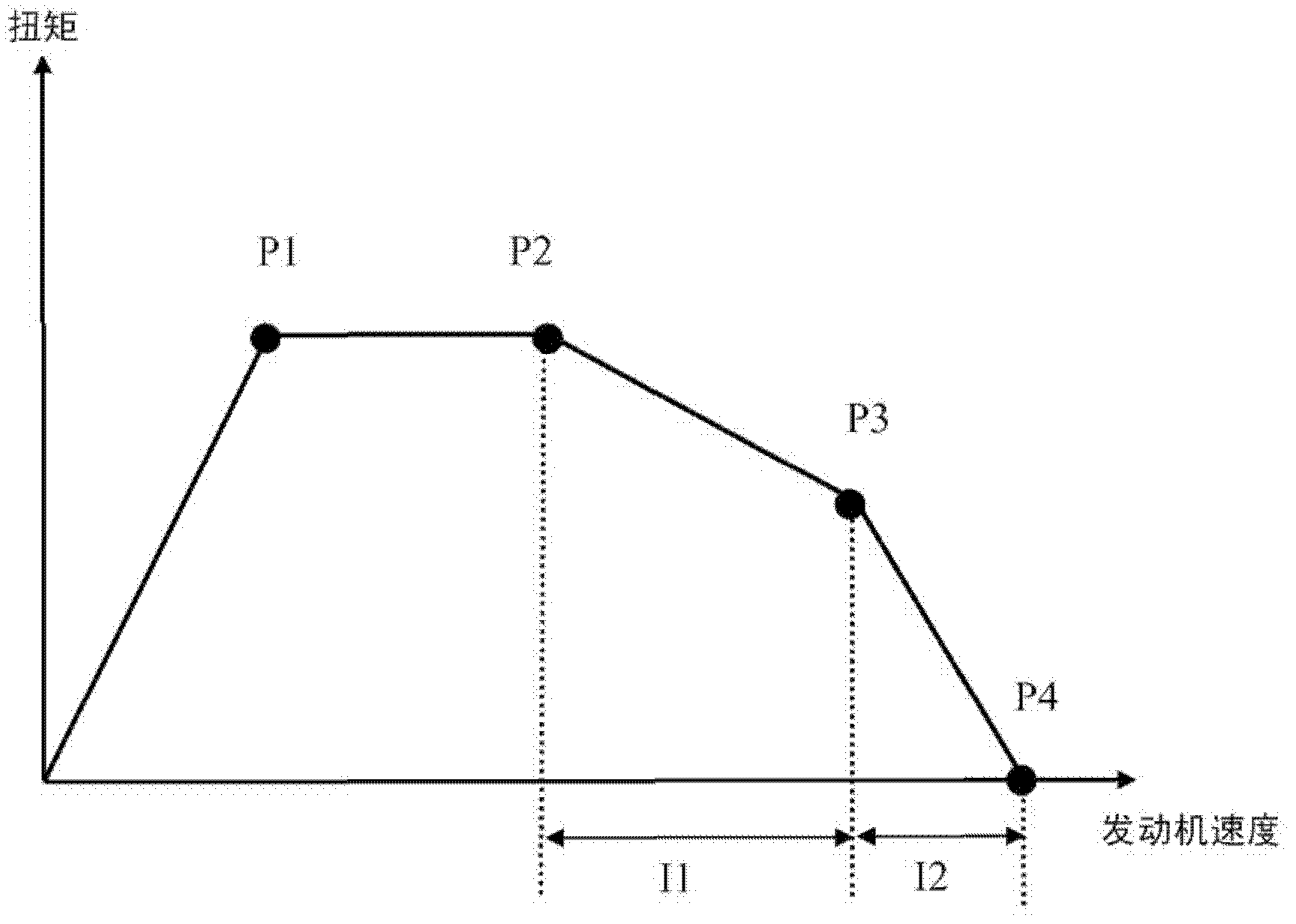

[0030] As noted above, conventional systems use tabulated shift points. Although these shift points are carefully calibrated by the vehicle manufacturer, driving conditions may vary and these calibrated shift points are not satisfactory in terms of handling flexibility. The full power output of the engine 10 also does not apply these calibrated shift points.

[0031] For example, when the vehicle 1 goes uphill, the state may rise, causing a shift point for an upshift, such as a single-stage acceleration, at a high engine speed where the vehicle 1 cannot accelerate to that engine speed. This situation means that although the motor vehicle 1 can accelerate in the next higher gear and thus reach a higher driving speed in that higher gear, an upshift cannot take place. To prevent this from happening, calibration often includes maintaining the upshift point at a low engine speed to enable an upshift. However, the result of this calibration is that the motor vehicle 1 appears to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com