Method for in situ synthesis of Y/beta composite molecular sieve

A composite molecular sieve, in-situ synthesis technology, applied in molecular sieve catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of weak acidity, single pore size, low activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

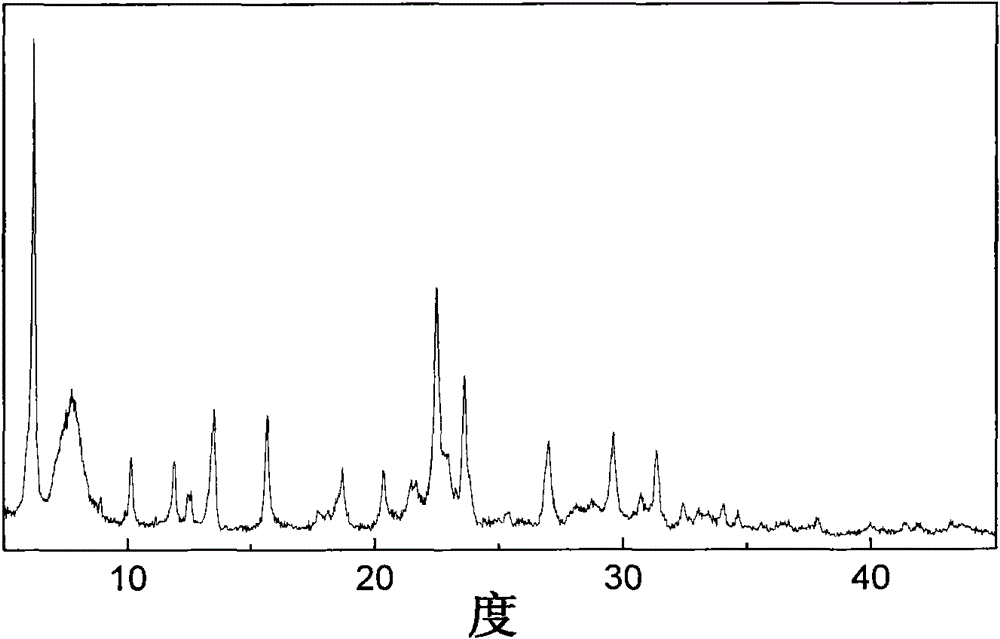

Image

Examples

Embodiment 1

[0020] First, dissolve 4.0g of sodium hydroxide and 1.7g of sodium aluminate in 35g of deionized water, and slowly add 14g of silica sol into the above solution after completely dissolving, stir well, and age at room temperature for 10 hours to obtain gel A; Next, dissolve 0.1g of sodium aluminate and 0.3g of sodium hydroxide in 10g of 25% tetraethylammonium bromide solution. After the solution is completely dissolved, slowly add 4g of coarse-pore silica gel into the above solution, and stir to obtain a condensate. Gel B; Finally, slowly add gel B to gel A, stir evenly at room temperature, put the above-mentioned final mixed gel into an autoclave, and crystallize at 100°C for 24h and at 140°C for 20h under autogenous pressure , taking out the crystallized product, washing with deionized water, filtering, drying and roasting to obtain a compound molecular sieve containing Y molecular sieve and β molecular sieve structure.

Embodiment 2

[0022] First, dissolve 4.3g of sodium hydroxide and 1.6g of sodium aluminate in 35g of deionized water, and slowly add 14g of silica sol into the above solution after completely dissolving, stir well, and age at room temperature for 6 hours to obtain gel A; Next, dissolve 0.25g of aluminum isopropoxide and 0.3g of sodium hydroxide in 16g of 15% tetraethylammonium bromide solution, after completely dissolving, slowly add 4g of white carbon black into the above solution, stir evenly to obtain Gel B; Finally, slowly add gel B to gel A, stir evenly at room temperature, put the above-mentioned final mixed gel into an autoclave, and crystallize at 100°C for 24h under autogenous pressure, and crystallize at 130°C After 24 hours, the crystallized product was taken out, washed with deionized water, filtered, dried and calcined to obtain a composite molecular sieve containing Y molecular sieve and β molecular sieve structures.

Embodiment 3

[0024] First, dissolve 3.1g of sodium hydroxide and 1.7g of sodium aluminate in 35g of deionized water, and slowly add 14g of water glass into the above solution after completely dissolving, stir well, and age at room temperature for 4 hours to obtain gel A; Next, dissolve 0.25g of aluminum isopropoxide and 0.3g of sodium hydroxide in 10g of 25% tetraethylammonium bromide solution, after completely dissolving, slowly add 4g of coarse-pore silica gel into the above solution, and stir evenly to obtain Gel B; Finally, slowly add gel B to gel A, stir evenly at room temperature, put the above-mentioned final mixed gel into an autoclave, and crystallize at 100°C for 24h under autogenous pressure, and crystallize at 120°C After 30 hours, the crystallized product was taken out, washed with deionized water, filtered, dried and calcined to obtain a composite molecular sieve containing Y molecular sieve and β molecular sieve structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com