Target model-based device monitoring system

A device monitoring and object model technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of flat namespace, unpredictable application system, inability to connect into a built-in relationship and interdependence, etc. , to achieve the effect of high cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

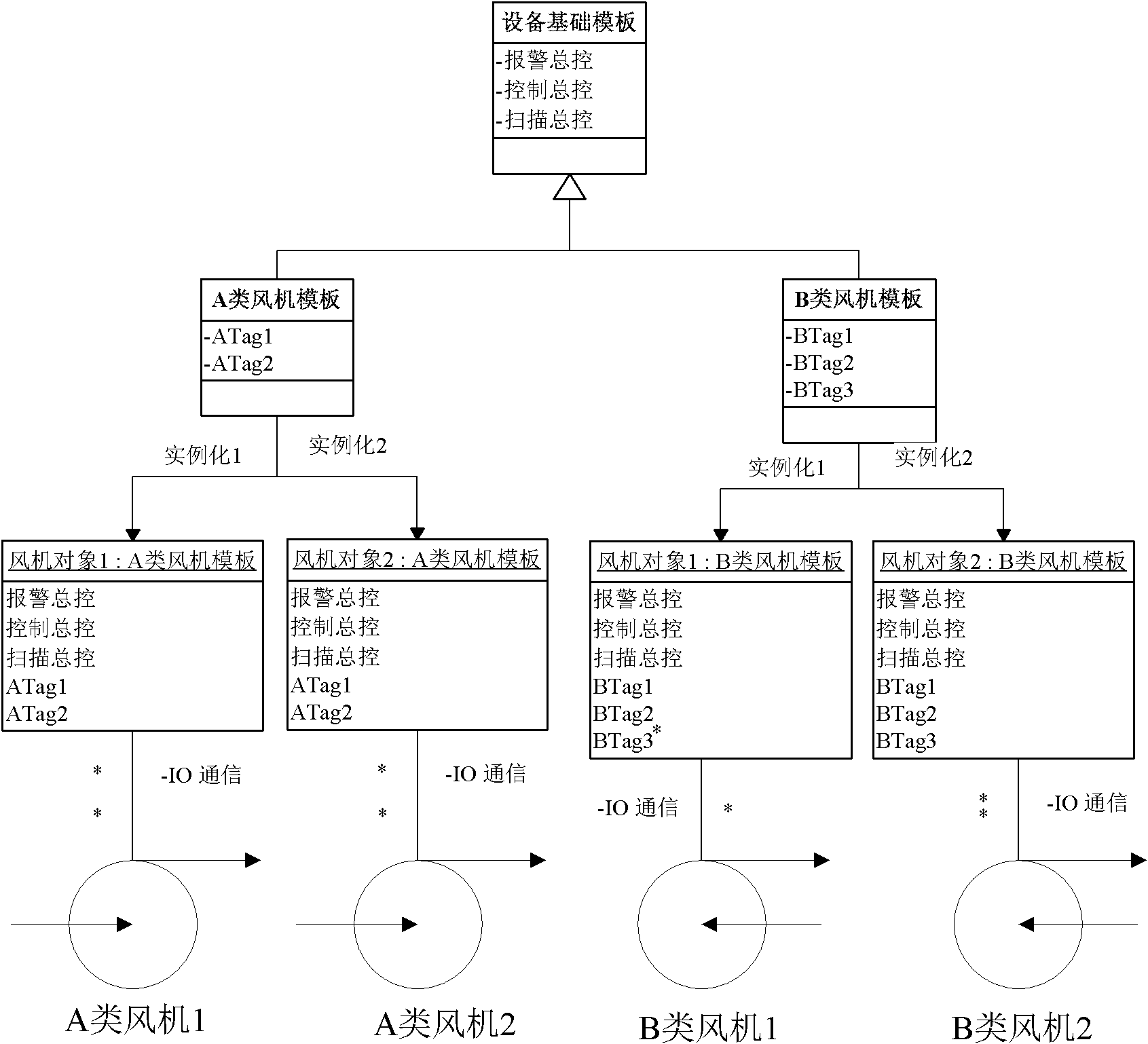

[0029] Embodiment one, such as figure 2 As shown, model the fan, instantiate multiple objects, and associate the objects with the actual equipment.

[0030] 1. Various logical master control switches are used as general attributes of the equipment basic class template;

[0031]2. According to the type of fan equipment, two types of fan templates are derived, and various physical I / O interfaces of related equipment types are used as the own attributes of the class template;

[0032] 3. There are four devices in total, A-type fans 1 and 2, and B-type fans 1 and 2. The two types of templates are instantiated respectively to obtain two objects, corresponding to A and B, a total of four fan devices;

[0033] 4. Finally, configure the I / O address on the corresponding physical device for the own attribute tag point of each object.

Embodiment 2

[0034] In the second embodiment, the power of the pump is calculated using calculation points.

[0035] 1. Configure the self-owned attributes tagI and tagU in the class template of the pump equipment, which respectively represent the input current intensity and voltage of the equipment;

[0036] 2. Configure the calculation point tagP, whose calculation formula is tagP=tagI*tagU;

[0037] 3. Instantiate the pump template and associate the object with the actual device, and collect the input current intensity and voltage value of the pump device in real time through the drive;

[0038] 4. Observe the input power of the equipment in real time through the calculation point tagP.

Embodiment 3

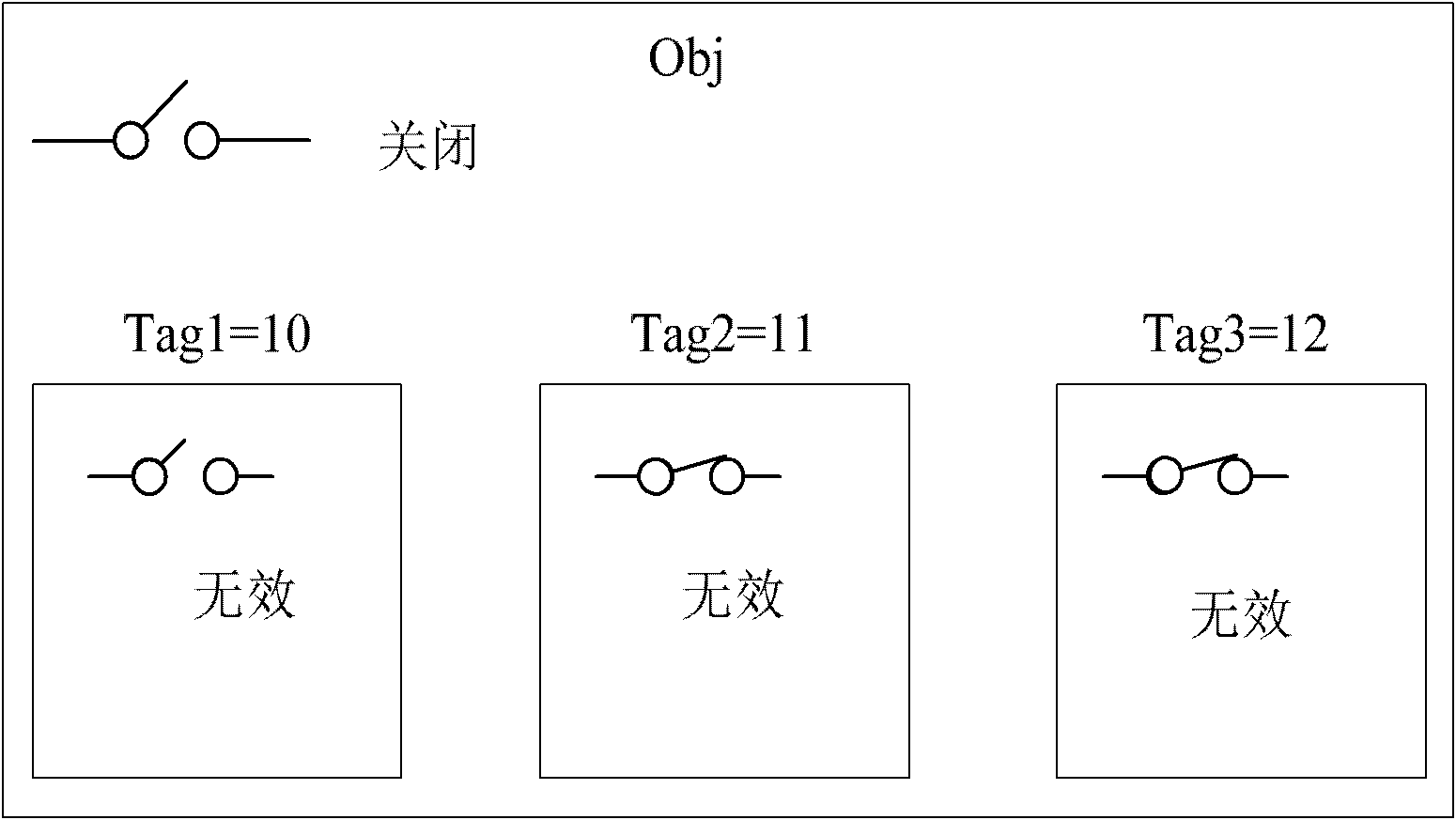

[0039] Embodiment 3, equipment data quality statistics.

[0040] 1. Add 100 own attributes in the class template of the fan equipment, named tag1, tag2, ..., tag100;

[0041] 2. Instantiate the claimed object FunObj, which is the subordinate variables tag1, tag3, tag5, ... of FunObj are respectively associated with valid device I / O addresses, and tag2, tag4, tag6, ... are associated with invalid addresses;

[0042] 3. Run the monitoring system and collect data from the fan equipment in real time;

[0043] 4. Observe the data quality statistics of FunObj. If everything is normal, the statistics should be 50, indicating that 50 tag points cannot collect data normally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com