Magnetic stirring hatching barrel

A magnetic stirring and magnetic technology, applied in the fields of climate change adaptation, fish farming, application, etc., can solve the problems of easy egg proliferation, escape of seedlings, unbalanced water inlet and outlet, and easy clogging of yarn, so as to achieve egg density. The effect of uniformity, high production efficiency and high hatching density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

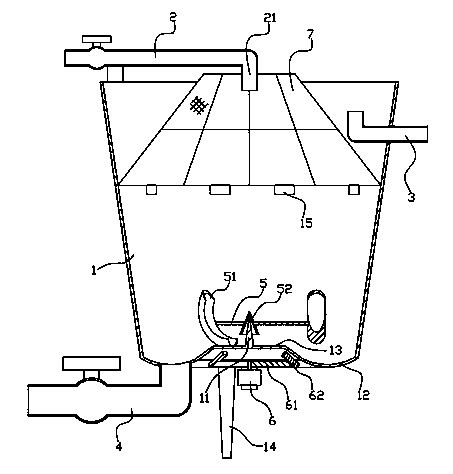

[0013] Example: refer to figure 1 , a magnetic stirring incubator, comprising a water tank 1 with support legs 14, wherein: the center of the bottom of the water tank 1 is formed with a raised boss 13, and the bottom between the boss 13 and the side of the water tank 1 has an annular groove 12; There is a thimble 11 near the center of the boss 13; the surface of the boss 13 located on the outside of the water tank 1 is connected with a magnetic rotating part; the thimble 11 is provided with a driven stirring mechanism 5 that can rotate with the magnetic rotating part; It has a matching cap 52, and the side circumference of the matching cap 52 is connected with a radially arranged boat-shaped stirring body 51; an inverted funnel-shaped screen tulle 7 is provided near the edge of the water tank 1; water pipe3. When the magnetic rotating part rotates, it drives the driven stirring mechanism 5. Under the action of the boat-shaped stirring body 51, the water body above the annular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com