Bottle cap washing and disinfecting machine

A technology for cleaning and disinfecting bottle caps, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as wasting resources, affecting the cleaning effect of bottle caps, and hygienic dead ends, so as to ensure filling Quality, improve disinfection effect, avoid the effect of hygienic dead ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

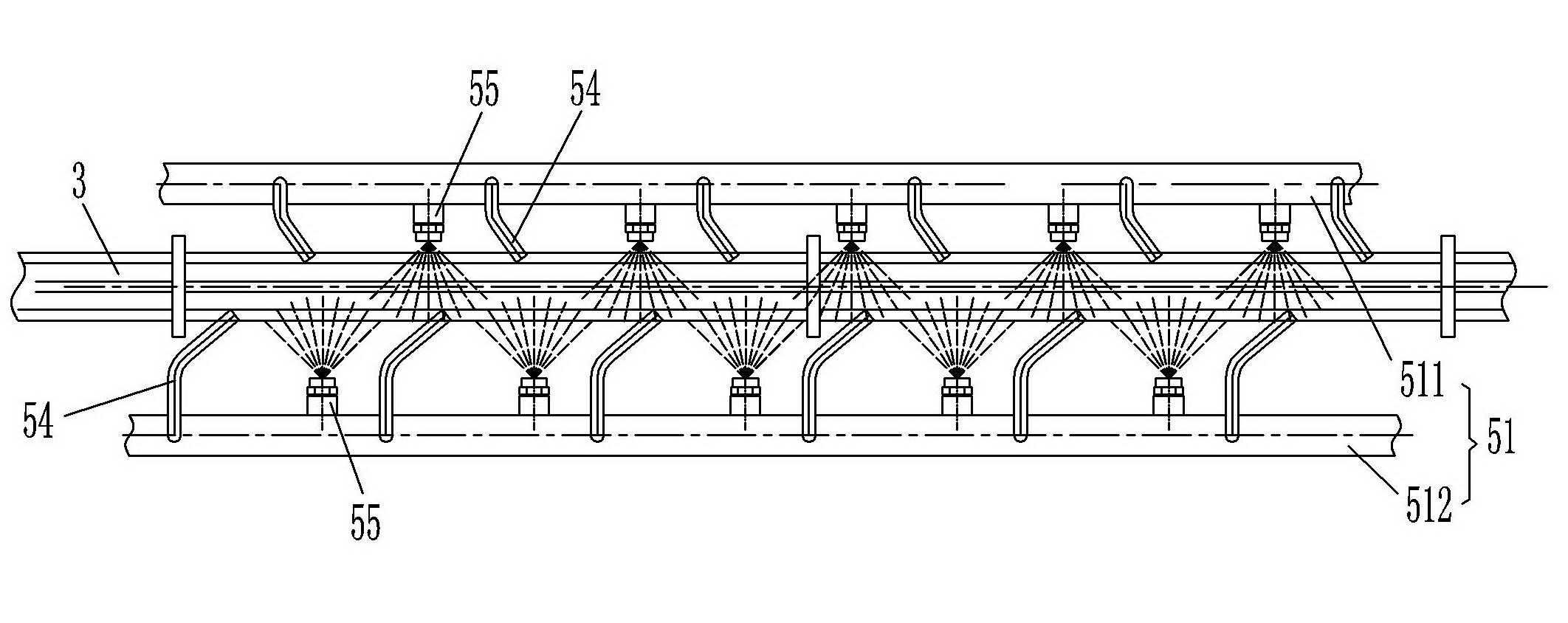

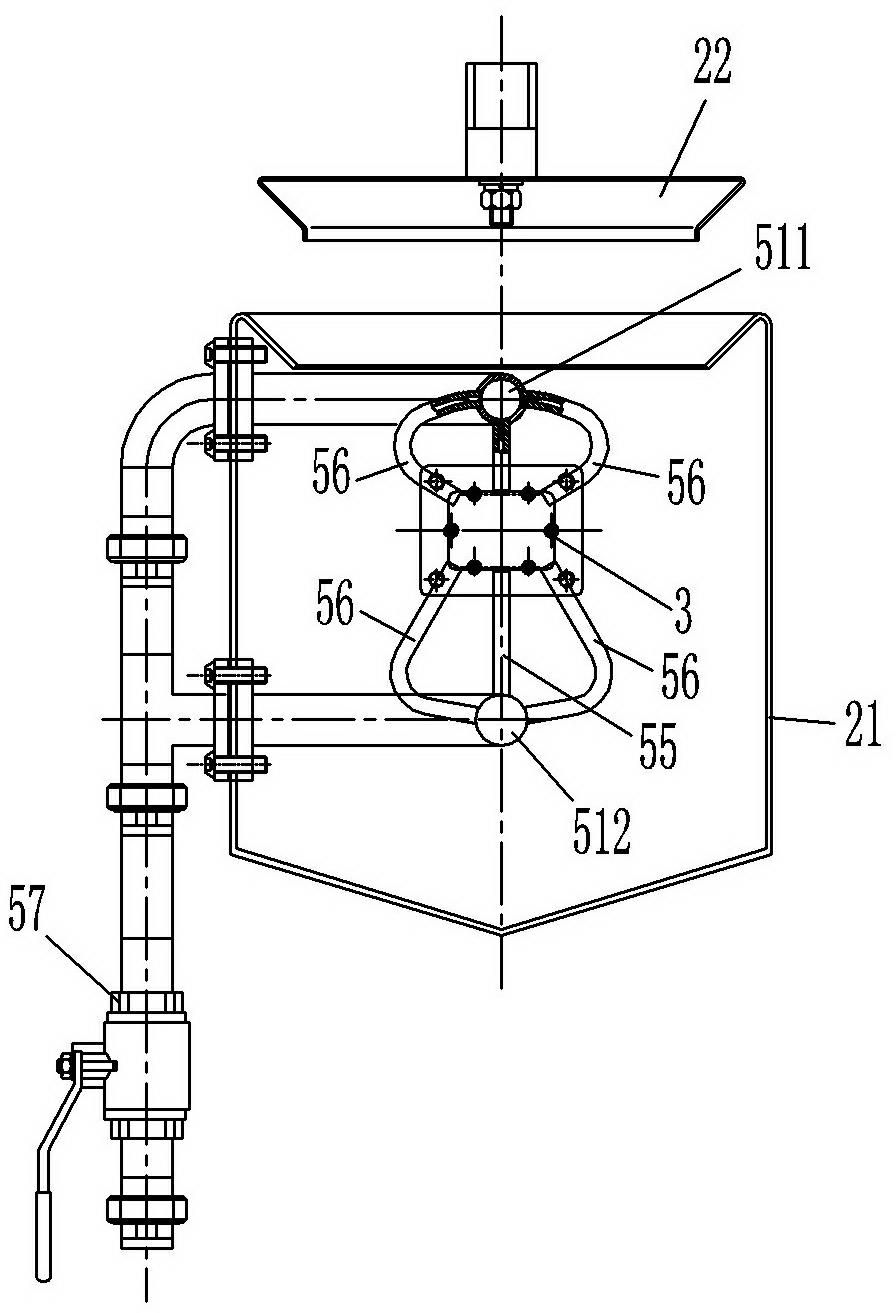

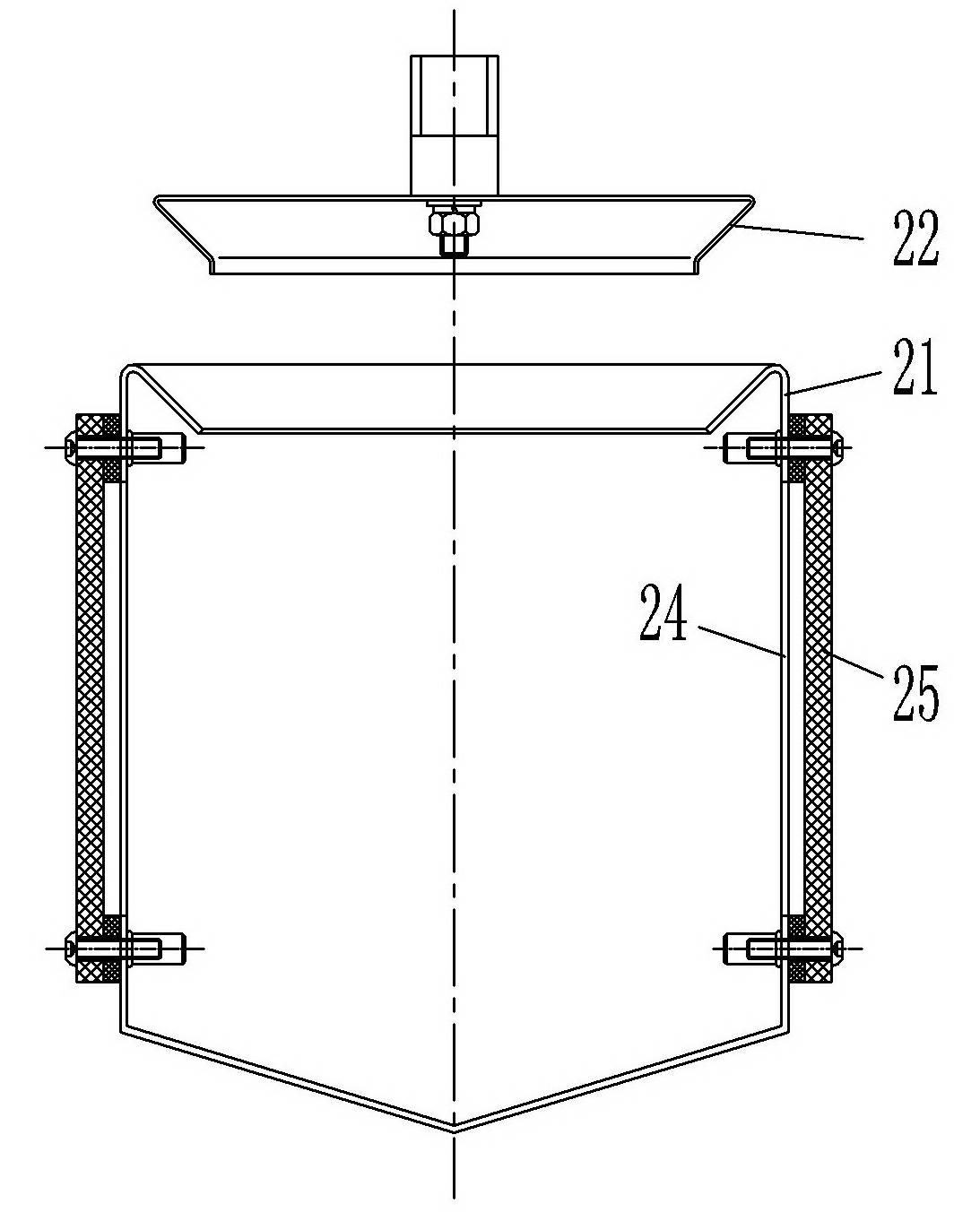

[0013] Such as Figures 1 to 3 As shown, the bottle cap cleaning and disinfecting machine of the present invention includes a bracket 1 and a cleaning tunnel 2 installed on the bracket 1. The cleaning tunnel 2 includes a housing 21 and a top plate 22. The cleaning tunnel 2 is provided with a cap delivery chute 3. The bottle cap inlet of the cap feeding chute 3 is connected to the bottle cap outlet of the cap unscrambler 4, and the inside of the cleaning tunnel 2 is provided with a medicine spray flushing device 5, a clean water spray flushing device 6, and a sterile Drying device 7, clear water spraying device 6 is connected with pure water supply equipment (not shown in the figure) through pipeline 63, aseptic blowing device 6 is then connected with sterile air filter (not shown in the figure), when working The cap unscrambler 4 provides orderly and continuous bottle caps for the cap delivery chute 3, and the bottle caps entering the cleaning tunnel 2 are cleaned and disinfec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com