Synchronous encoding control device of periphery drive concentrator

A technology of synchronous control and peripheral transmission, applied in chemical instruments and methods, separation methods, precipitation separation, etc., can solve the problems of easy failure, thickener failure, high failure rate of thickener, etc., to achieve easy operation, simple positioning, The effect of reducing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

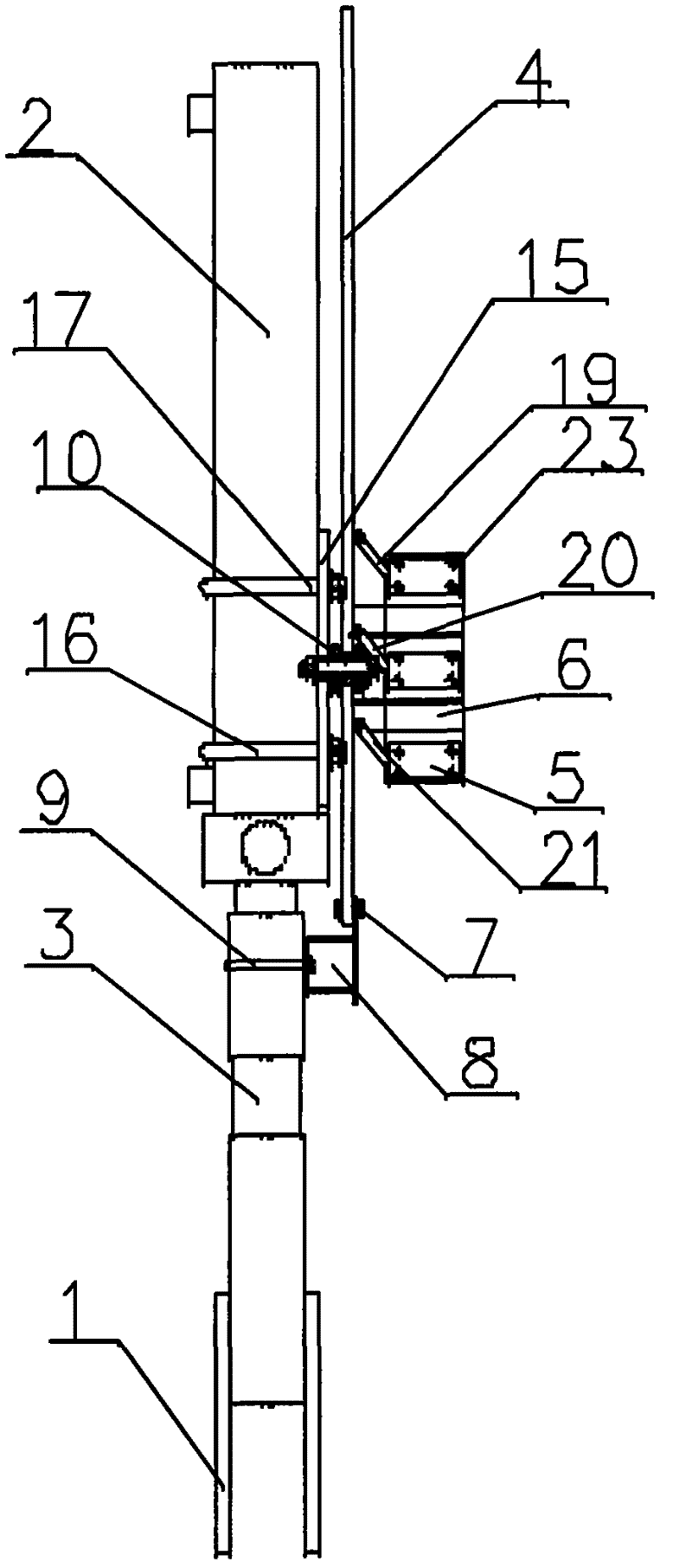

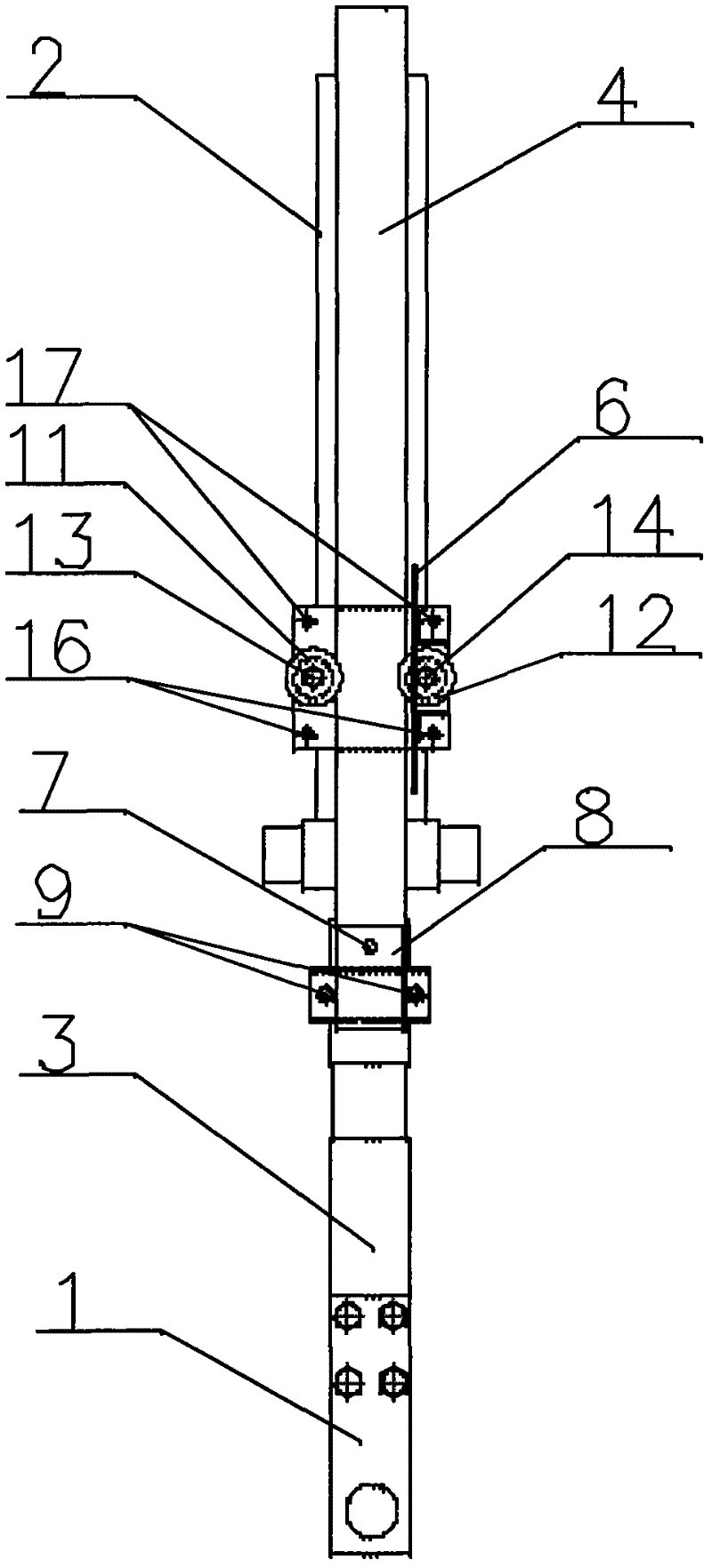

[0016] Example as figure 1 , figure 2 As shown, the scraping device of the peripheral transmission concentrator is composed of a rake frame 1, an oil cylinder 2, and a coding synchronization control device. The telescopic action independently adjusts the working height of the rake frame 1. The encoding synchronization control device includes an encoding moving scale 4, a travel switch 5 and a travel switch fixing bracket 6. The lower end of the coded mobile scale 4 is fixed on the fixed splint 8 through the bolt 1, and the fixed splint 8 is fixed on the cylinder rod 3 through the U-shaped bolt 9; In the groove of the guide wheel 10, the guide wheel 10 on the oil cylinder 2 is provided with a guide wheel 11 and a guide wheel 2 12, and the guide wheel 11 and the guide wheel 12 are respectively fixed on the guide wheel plate by the bolt 2 13 and the bolt 3 14 On both sides of 15, guide wheel plate 15 is fixed on the oil cylinder 2 by U-shaped bolt two 16 and U-shaped bolt thr...

Embodiment 2

[0019] Example two such as Figure 4 As shown, the travel switch one 19, the travel switch two 20, the travel switch three 21 and the travel switch four 22 on the travel switch fixed bracket 6 of the present embodiment are used in conjunction with the coded mobile scale 4, then according to the principle of binary coding, four strokes The switch 5 has just formed sixteen working states, showing eight height states of the rake frame 1 in the thickening tank, and other settings of the present embodiment are the same as the embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com