Automatic spraying device and spraying method

A technology of automatic spraying and powder trough, which is applied in the direction of spraying device, device for coating liquid on the surface, coating, etc. It can solve the problems of slow spraying speed, waste of paint, uneven coating, etc., and achieve fast spraying speed and structure Reasonable, easy-to-use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

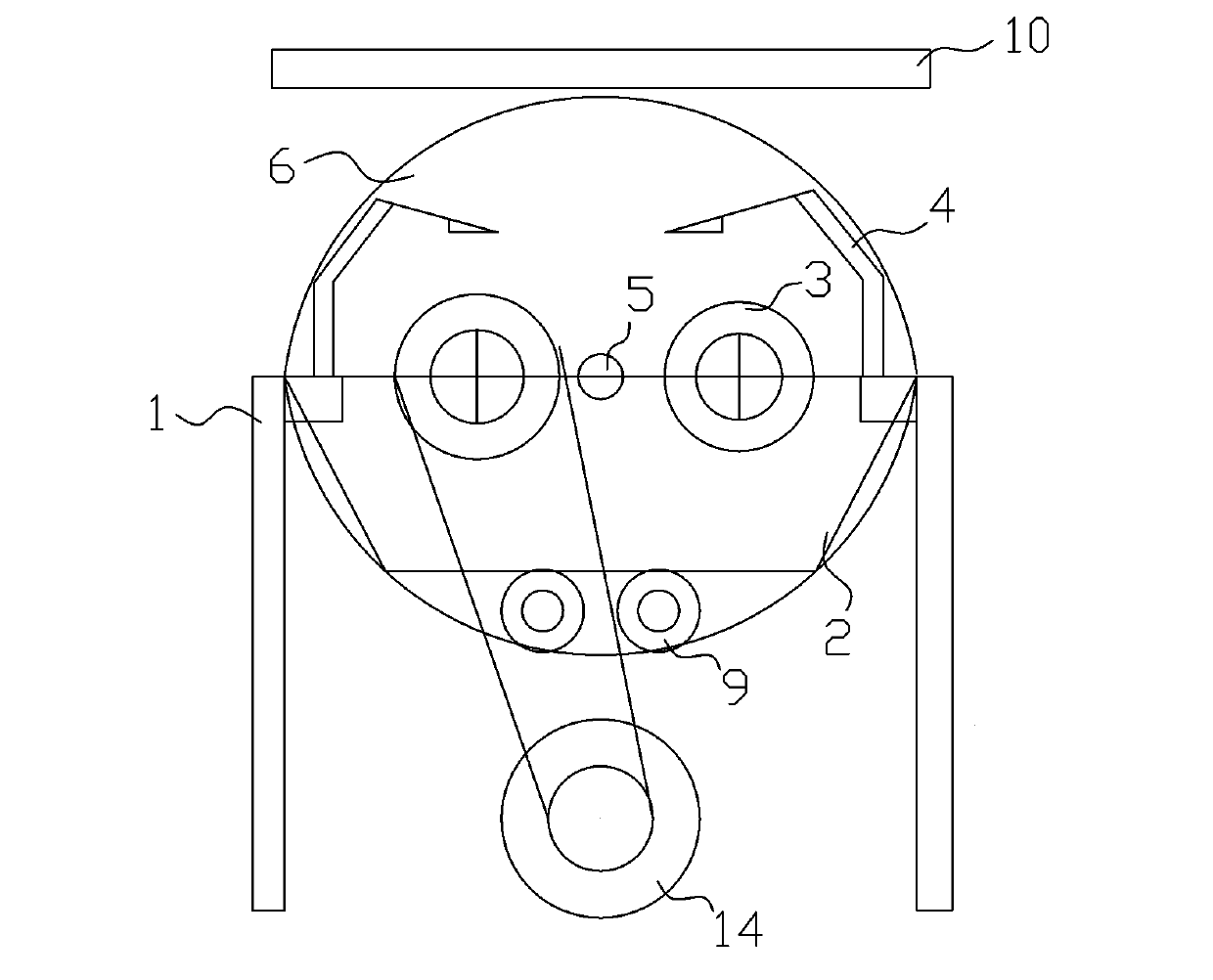

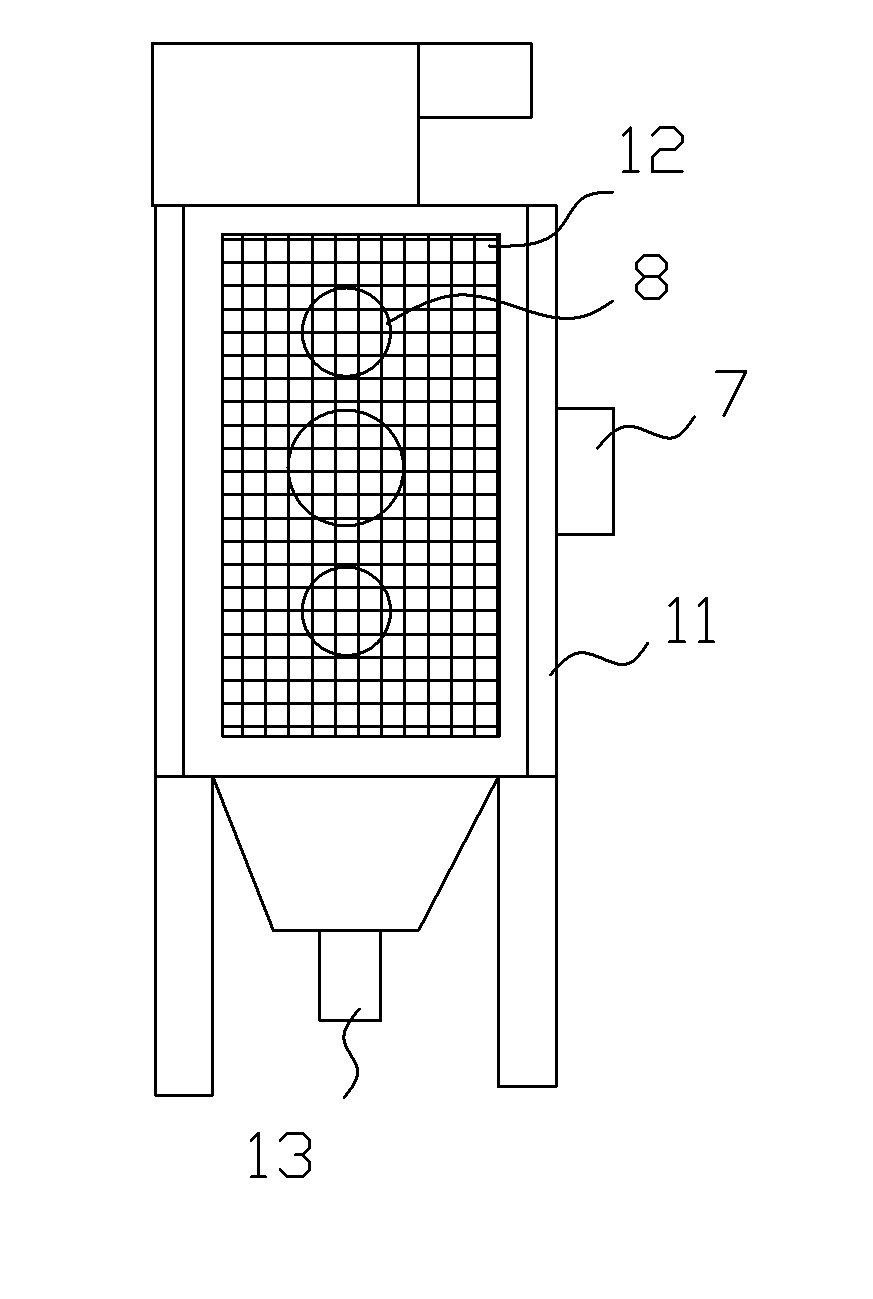

[0021] Example: The automatic spraying device of the present invention comprises a bracket 1, a powder tank 2 arranged on the bracket, two roller racks 3 placed horizontally above the powder tank to drive the steel pipe to be sprayed to rotate, and an external spray gun 4, which is arranged on The outer side of one end of the spraying device can extend into the inner spray gun 5 inside the steel pipe to be sprayed, and at least one outer spray gun is fixed on the supports on both sides of the roller frame; The cover 6 slides into the bottom of the powder tank 2. When closed, the tank cover 6 slides to the space above the powder tank 4 and seals the outer spray gun inside the tank cover; one side of the powder tank is provided with an air inlet 7, and the bottom is provided with a recycling powder inlet 8. Connect to the powder recovery device through the powder outlet 13 of the recovery pipeline 9; air curtain machines 10 are respectively installed above the two ends of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com