Rotary trimming shears of which lateral clearances and overlapping quantities of cutterheads can be subjected to closed-loop regulation and control

A closed-loop adjustment and overlap technology, applied in shearing devices, shearing machines, manufacturing tools, etc., can solve problems such as unreliability and low adjustment accuracy, and achieve the effect of improving adjustment accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

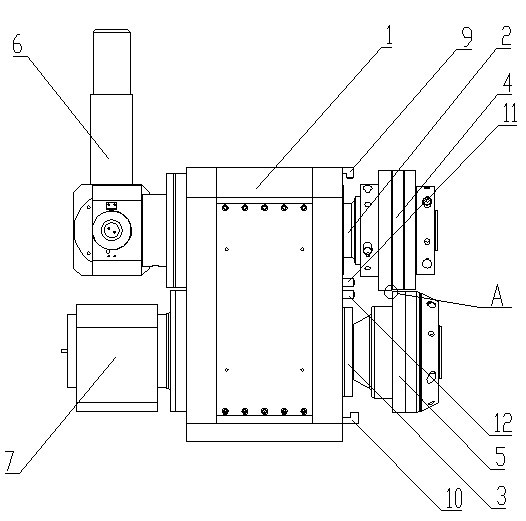

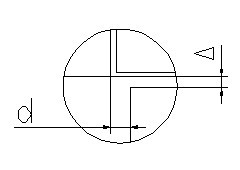

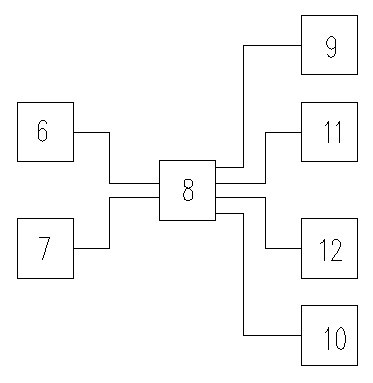

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings: the disc trimming shears with closed-loop adjustment and control of the side clearance of the cutter head and the overlapping amount of the present embodiment include a trimming shear device and an adjustment control system, and the trimming shear device includes Tool holder 1, upper cutter shaft 2 and lower cutter shaft 3 arranged on the tool holder 1, upper cutter head 4 and lower cutter head 5 respectively fixed on one end of upper cutter shaft 2 and lower cutter shaft 3 to form a shearing structure 1. A side gap adjustment motor 6 and an overlap adjustment motor 7 for adjusting the side gap d and the overlap amount Δ of the upper and lower cutter heads respectively. The adjustment control system includes a controller 8, an upper cutter shaft position detection sensor 9, a lower cutter Shaft position detection sensor 10, upper cutter head position detection sensor 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com