Plate glass edging equipment and method

A technology for edging equipment and flat glass, applied in grinding/polishing equipment, metal processing equipment, machine tools suitable for grinding workpiece edges, etc. Operation, reducing the labor intensity of workers, reducing the effect of mechanical vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing, the content of the present utility model is further described.

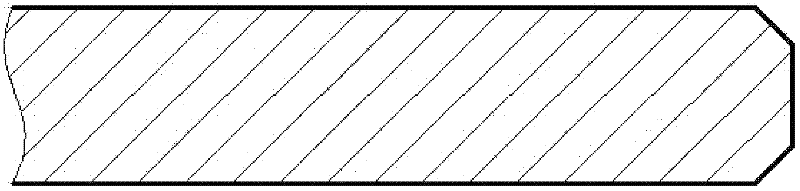

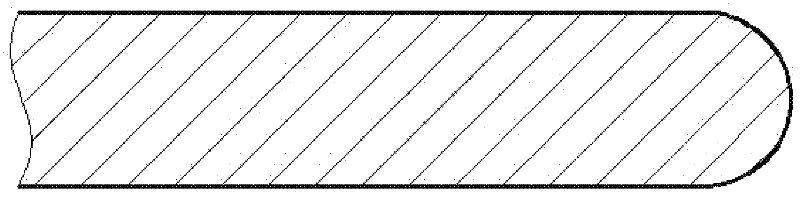

[0038] like figure 1 The schematic diagram of the glass edge after chamfering is shown and as figure 2 The schematic diagram of the glass edge after rounding is shown. In production and processing, the general processing is as follows figure 1 The chamfered edge shown requires a belt edging mechanism, while processing such as figure 2 The rounded edge shown requires a grinding wheel edging mechanism.

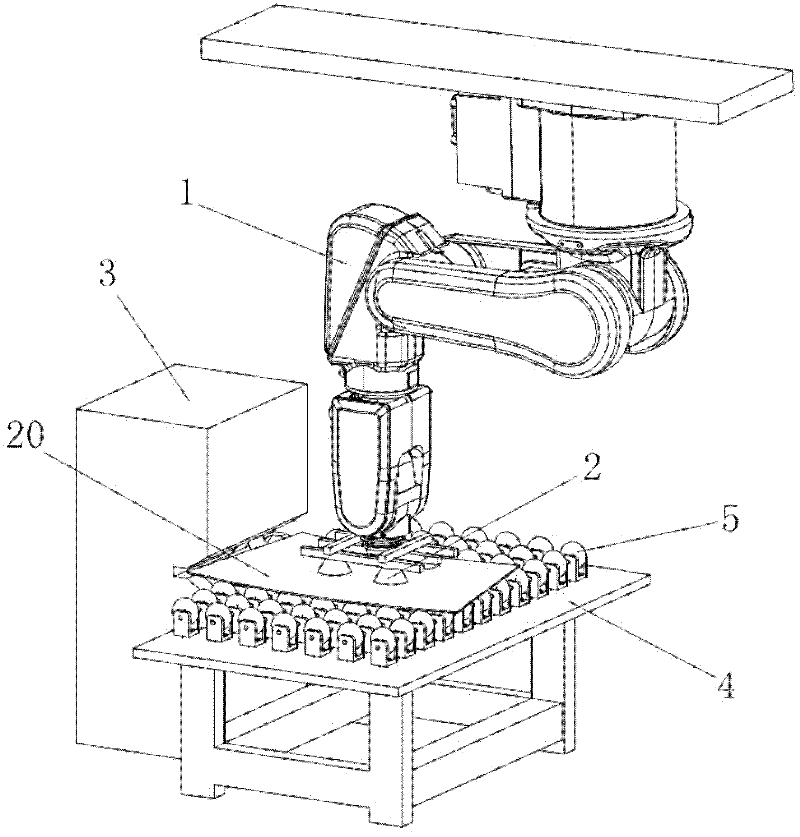

[0039] like image 3 The first embodiment of the present invention is shown. In this embodiment, the edging equipment of the present invention includes a robot arm 1, a glass adsorption device 2, an abrasive belt edging mechanism 3 and an edging workbench 4. The glass adsorption The device 2 is fixed on the end 1 of the robot arm, and is characterized in that: a plurality of universal rollers 5 are arranged on the upper surface of the edging workbench 4, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap