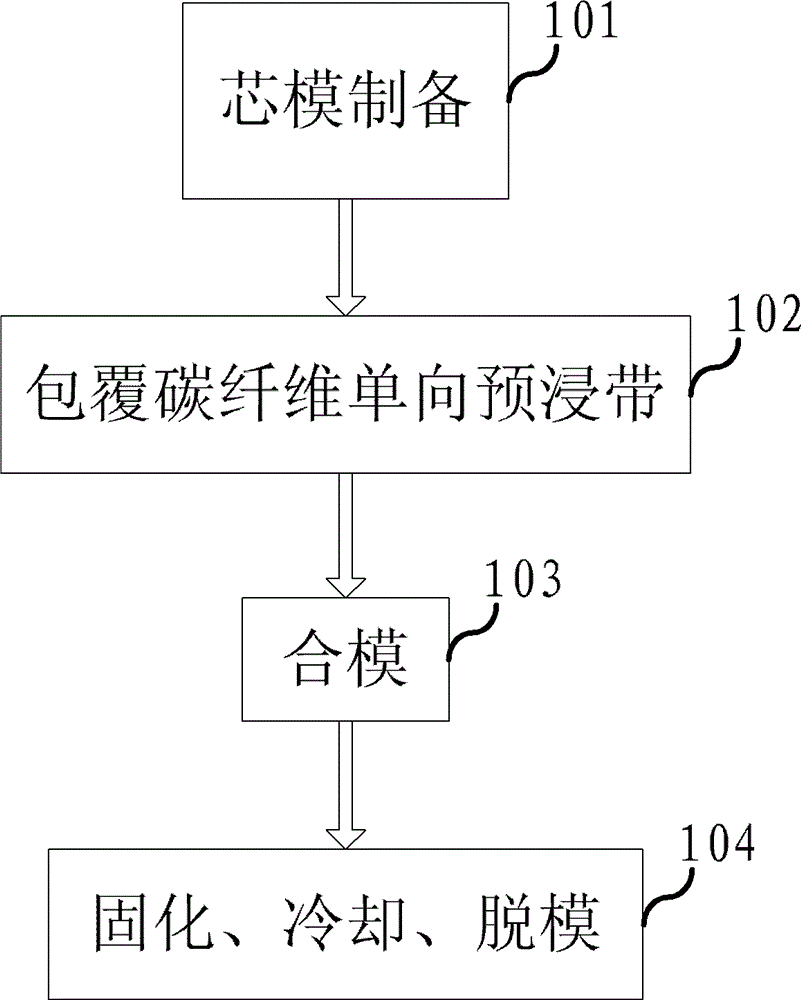

Method for forming carbon fiber pipe and die thereof

A molding method and carbon fiber technology, which are applied to the molding method of carbon fiber pipes and the field of molds, can solve the problems of layering, difficulty in mold clamping, low production efficiency, etc., and achieve good quality stability, uniform product wall thickness, and low manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

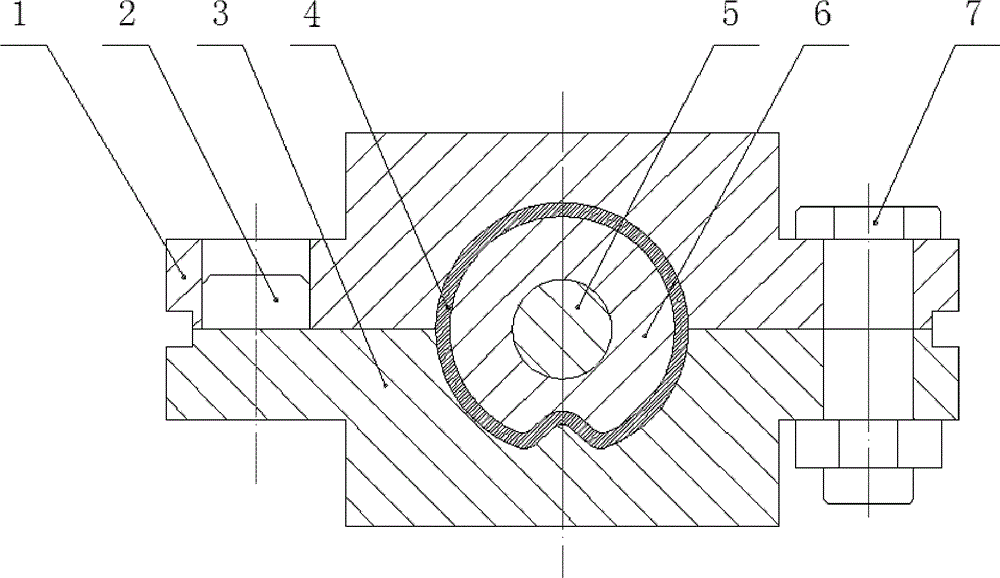

Embodiment 1

[0067] Adopting the above-mentioned carbon fiber pipe forming method to manufacture an outer diameter of φ28mm, a wall thickness of 1.5mm, and a length of 280mm is a grooved carbon fiber foot tube of a photographic tripod. Make a mandrel with a metal mandrel diameter of φ11 and a rubber material thickness of 7mm. The metal mandrel and the rubber are firmly bonded with a special adhesive based on silicone rubber material. Cut 8 layers of T7000SC-12K carbon fiber unidirectional prepreg tape, and the fiber angles from the first layer to the eighth layer are 0°, 45°, -45°, 0°, 15°, -15°, 5°, - 5°, each layer of the cut carbon fiber unidirectional prepreg tape is manually wrapped on the mandrel according to the angle. Align the core mold with the female mold and fasten it with bolts. Put the mold into the oven, after the carbon fiber unidirectional prepreg tape is cured, it is cooled to below 60°C with the furnace, and the mold is demoulded to form the required carbon fiber legs ...

Embodiment 2

[0070] The above-mentioned carbon fiber pipe forming method is used to manufacture the carbon fiber foot pipe of the photography tripod. The main difference from the above-mentioned Example 1 is that the diameter of the metal mandrel is increased to φ11.5, and the thickness of the rubber material is still 7mm; the carbon fiber unidirectional prepreg tape is paved with a 6-layer structure, and each fiber from the first layer to the sixth layer The cladding angles are 0°, 45°, -45°, 0°, 5°, -5°, and other materials, processes and parameters remain unchanged, and the carbon fiber legs of the photography tripod are made. After testing, the surface and internal quality of the workpiece are the same as in Example 1, that is, the surface is smooth, free of air bubbles, and there is no crispness or delamination inside; meanwhile, the longitudinal strength of the workpiece is basically equal, but the transverse strength is slightly reduced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com