Hybrid power system for hydraulic system and engineering machine

A technology of hybrid power system and hydraulic system, which is applied in the field of power system, can solve the problems of complex hydraulic system pipeline and oil circuit control, inability to realize frequency conversion speed regulation and energy saving, and too simple design of electrical parts, so as to improve safety and Energy-saving efficiency, high work efficiency, and convenient operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to understand the above-mentioned purpose, features and advantages of the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] In the following description, many specific details are set forth in order to fully understand the present invention, but the present invention can also be implemented in other ways different from those described here, therefore, the present invention is not limited to the specific embodiments disclosed below limit.

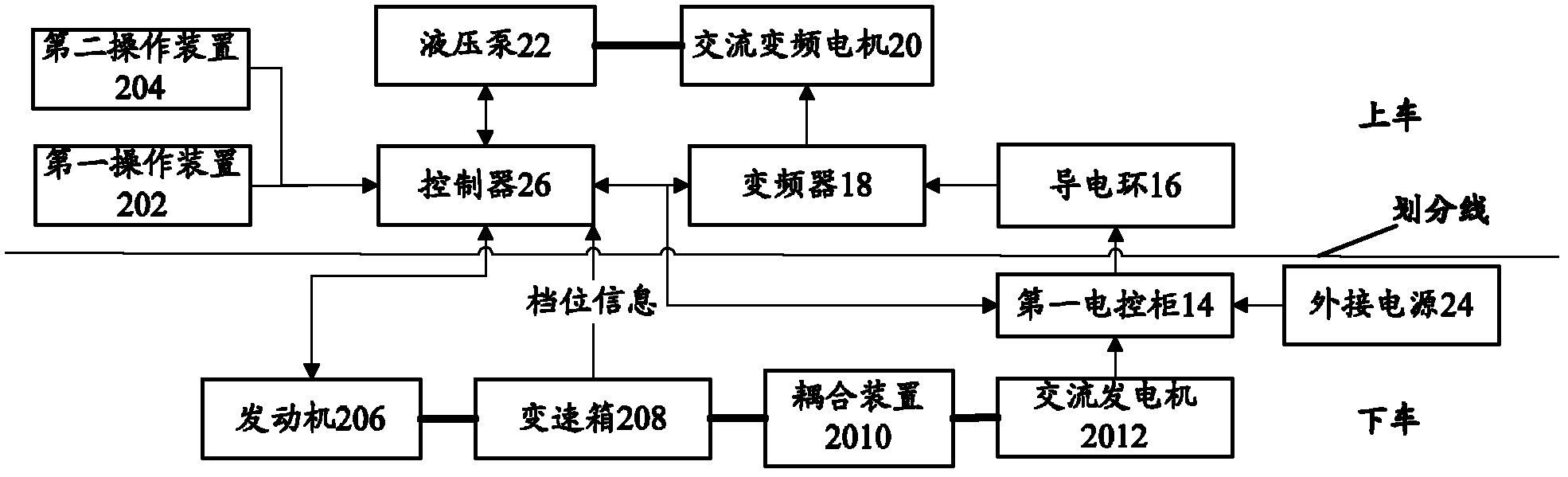

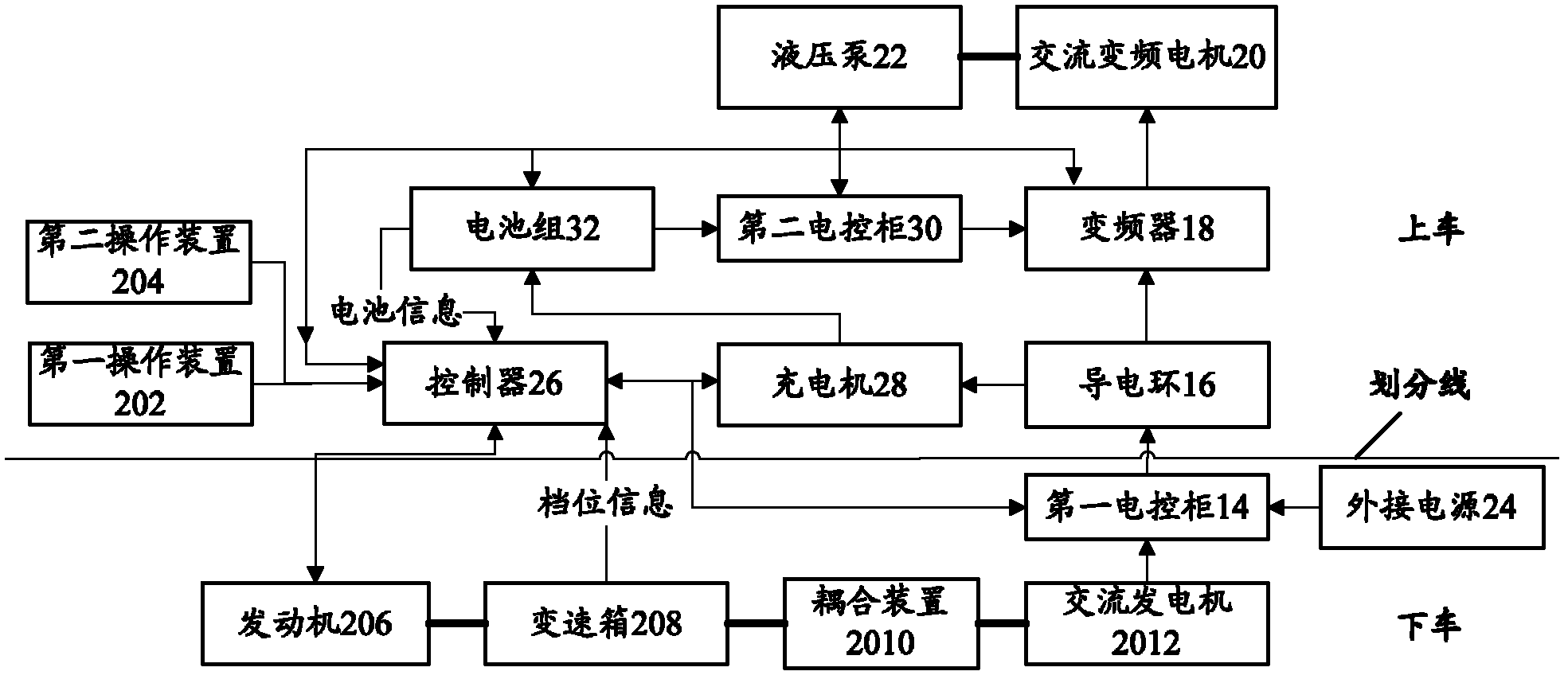

[0034] figure 2 A schematic diagram of a hybrid system for a hydraulic system according to an embodiment of the present invention is shown.

[0035] Such as figure 2As shown, in the hybrid power system for the hydraulic system according to the embodiment of the present invention, the engine 206, the gearbox 208, the coupling device 2010, the alternator 2012, the frequency converter 18, the AC vari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com