Electric mountain orchard single-rail transporting machine

A single-track, transporter technology, applied in transportation and packaging, motor vehicles, rack railways, etc., can solve the problems of high noise of diesel or gasoline engines, affecting the ecological balance of the surrounding environment, and high cost of ropeway freight engines, and achieve long service life. , Improve work efficiency and economic benefits, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

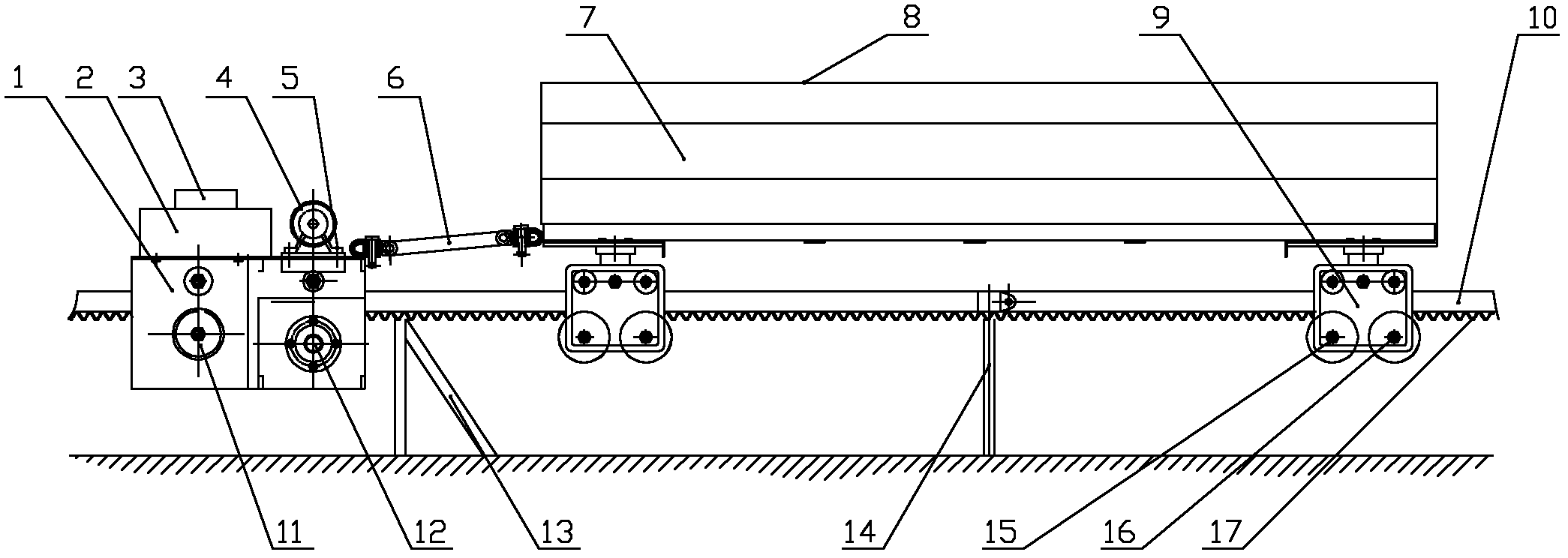

[0042] An electric mountain orchard single-track conveyor of the present invention includes a tractor and a transport trailer 7, and the tractor and the transport trailer 7 ride on an erected track 10 with a rack 17 below.

[0043] figure 1 As shown, the tractor includes: a main frame 1, a storage battery 2, a control device 3, a braking device, a motor and a planetary reducer 4, a motor base 5, a guide clamping wheel set 11, a transmission device 12 and a driving device. The main frame 1 is cut and welded by No. 45 steel plates with a thickness of 10 mm.

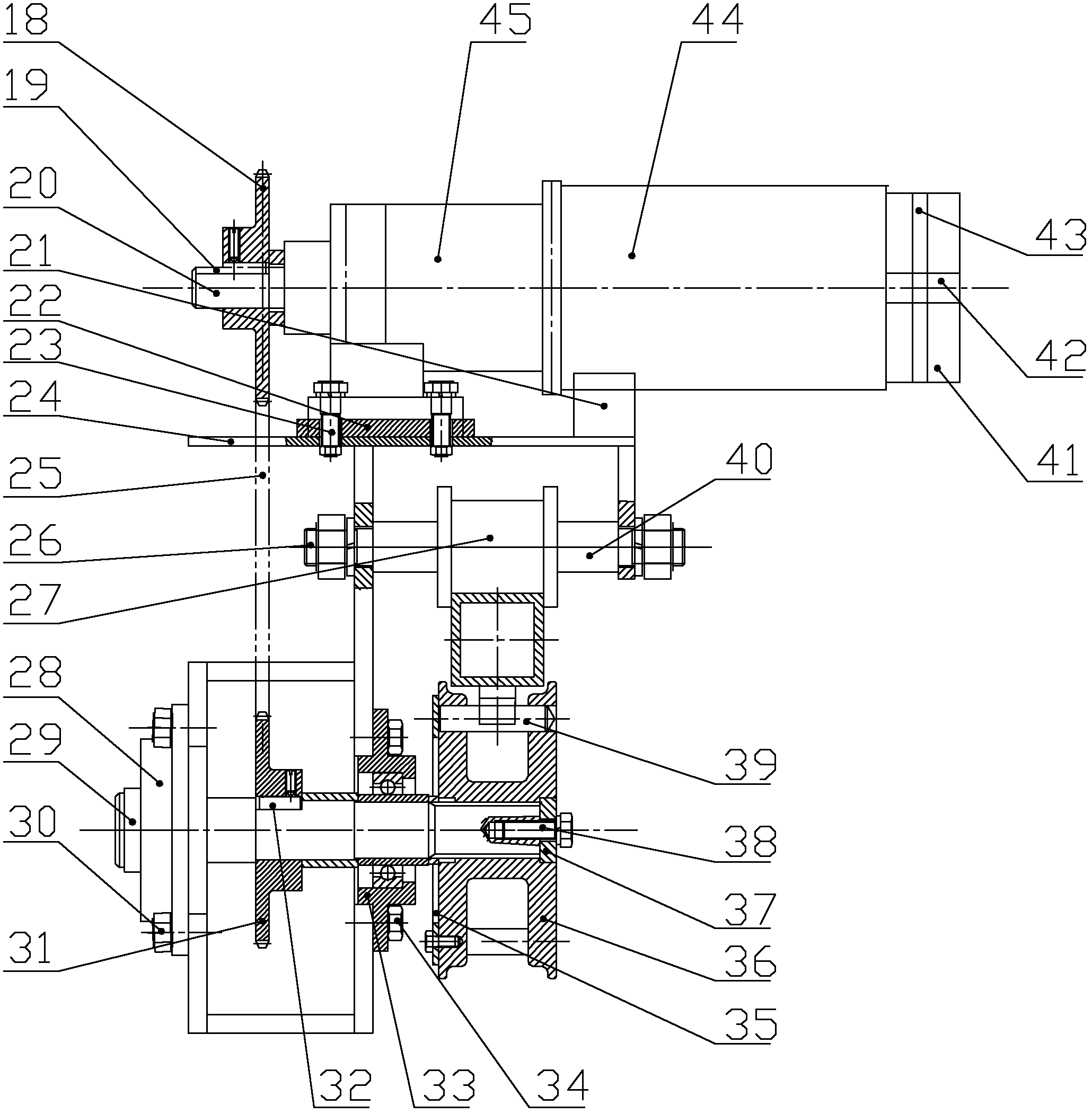

[0044] Among them, such as figure 2 As shown, the motor 44 is installed above the main frame 1 , and a motor spacer 21 is placed between the main frame 1 . The left end of the motor 44 is connected to the planetary reducer 45 , and the planetary reducer 45 is connected to the power o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com