Nondestructive testing method for compaction quality of rock-soil filled foundation

A technology for compaction quality and non-destructive testing. It is applied in the field of foundation soil survey, infrastructure engineering, construction, etc. It can solve the problems of difficulty in formulating compaction standards, large influence of softness, and restricted development, so as to avoid measuring points. The effect of poor representativeness, high detection accuracy and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The non-destructive testing method for testing the compaction quality of soil-rock mixed filling foundation provided by the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

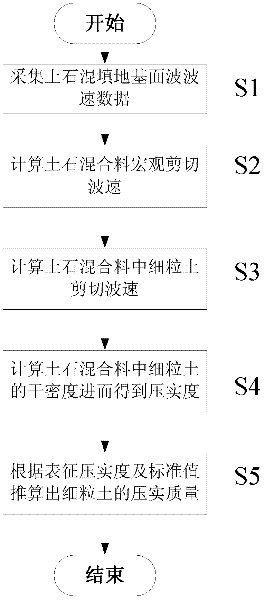

[0015] Such as figure 1 As shown, the non-destructive testing method for detecting the compaction quality of earth-rock mixed filling foundation provided by the present invention includes the following steps carried out in order:

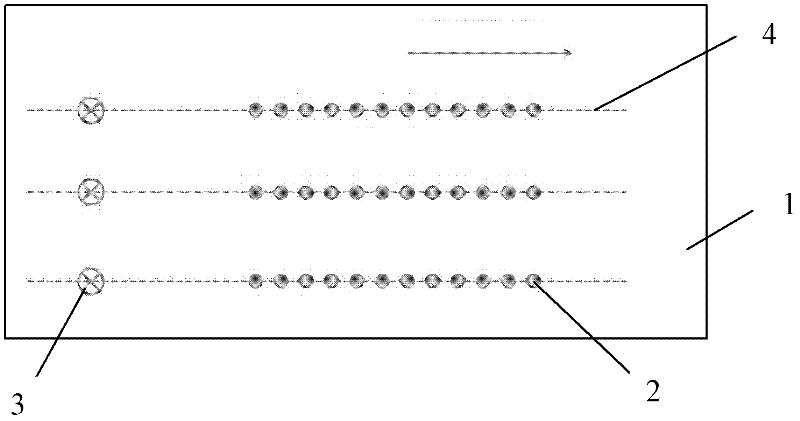

[0016] 1) The S1 stage of collecting soil-rock mixed filling foundation surface wave velocity data: in this stage, if figure 2 As shown, multiple rows of surface wave detectors 2 arranged at intervals are arranged in parallel in the middle of the surface of the soil-rock mixed foundation 1, and multiple rows of surface wave detectors 2 are selected on the surface side of the soil-rock mixed foundation 1 respectively. 2 Hammering point 3 located on the same straight line, and then use hammering, fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com