Self-stirring type dredging device for river channels

A stirring, river channel technology, applied in construction, earth mover/shovel, etc., can solve problems such as restricting agricultural industrial structure, frequent replacement, affecting agricultural industrial structure, etc., to improve flood control and drought resistance, and reduce sedimentation. , the effect of good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

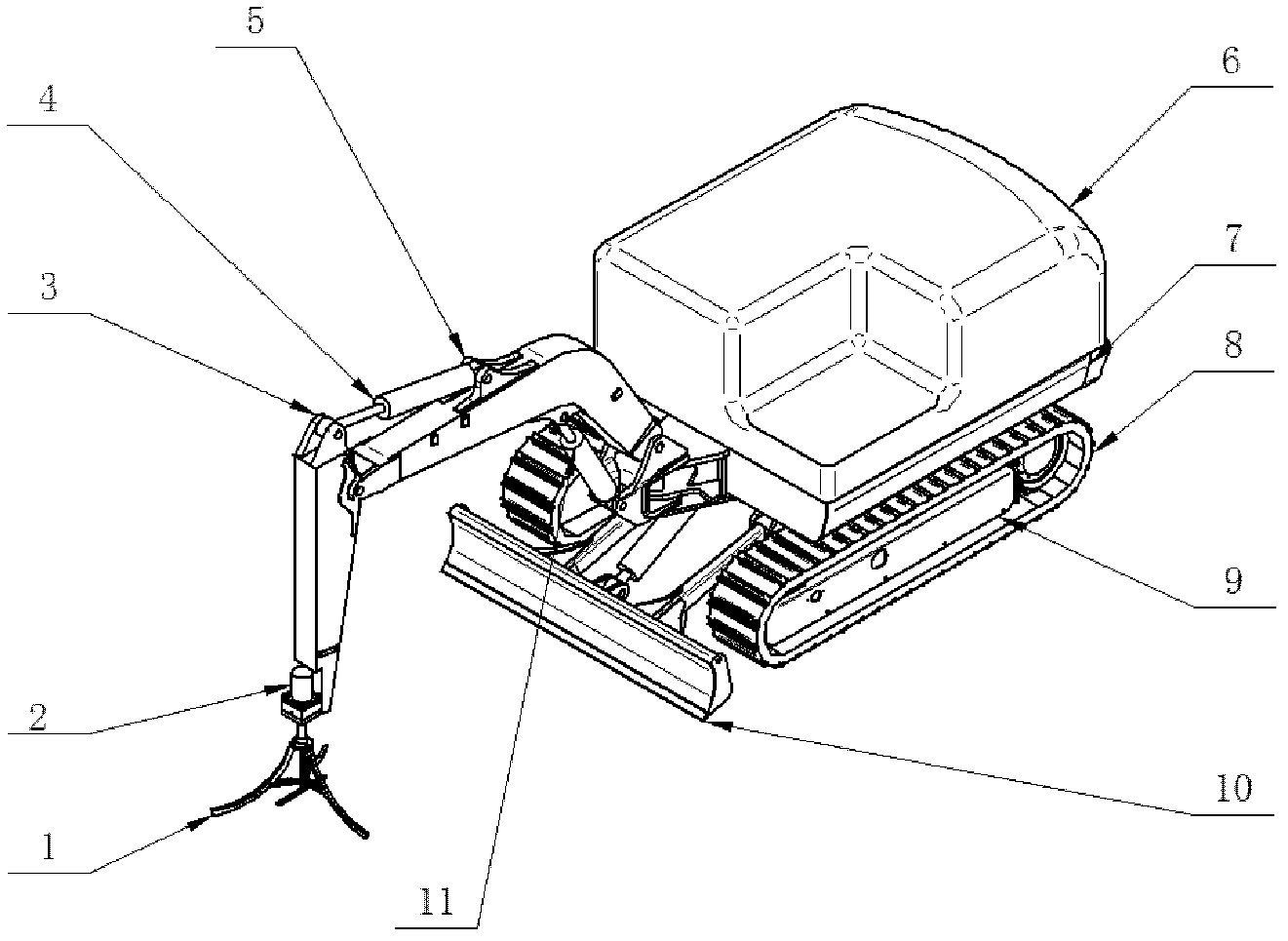

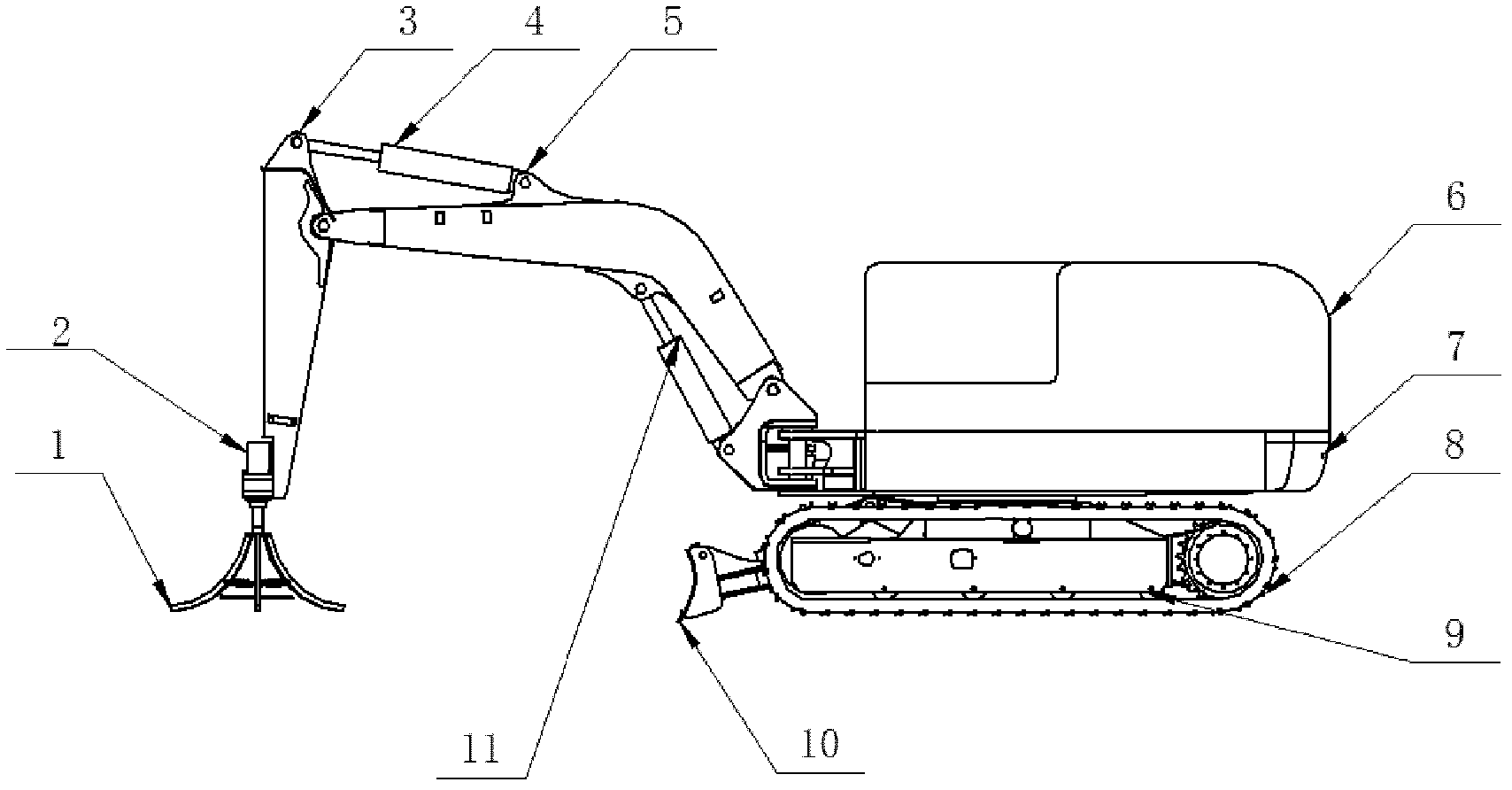

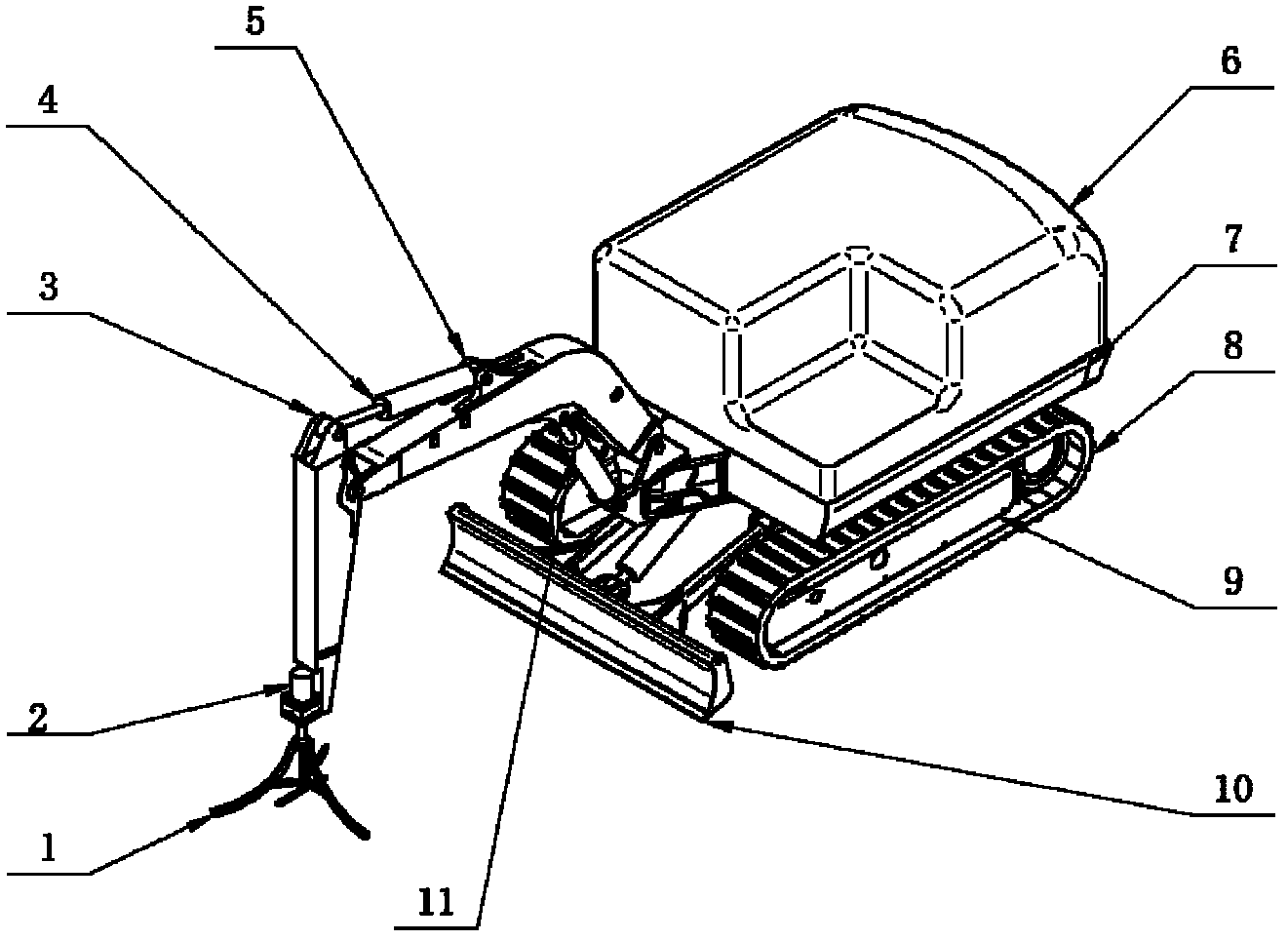

[0026] Such as figure 1 , 2 As shown, the present invention combines the rotary stirring device 1 with the technology of crawler excavators and underwater walking robots for full reference. It includes: rotating stirring device 1, rotating hydraulic motor 2, stick assembly 3, stick cylinder 4, boom assembly 5, closed power assembly 6, main frame assembly 7, rubber track 8, walking assembly 9. Bulldozing device 10, boom cylinder 11, the main frame assembly 7 is installed on the travel assembly 9, rubber crawlers 8 are installed on both sides of the travel assembly 9, and the closed power assembly 6 is installed on the main frame assembly 7 Above, the stick assembly 3 is hinged with the boom assembly 5, the stick cylinder 4 is hinged with the stick assembly 3 and the boom assembly 5 respectively, the boom assembly 5 is hinged with the front end of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com