Automatic-control casing valve

A technology of casing valve and casing shorting, which is applied in the direction of wellbore/well valve device, wellbore/well parts, earthwork drilling and production, etc. It can solve the problems of oil pipeline deformation and troublesome installation and operation, and achieve the goal of installation and operation. Simple, troublesome installation and operation, safe and reliable drilling operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

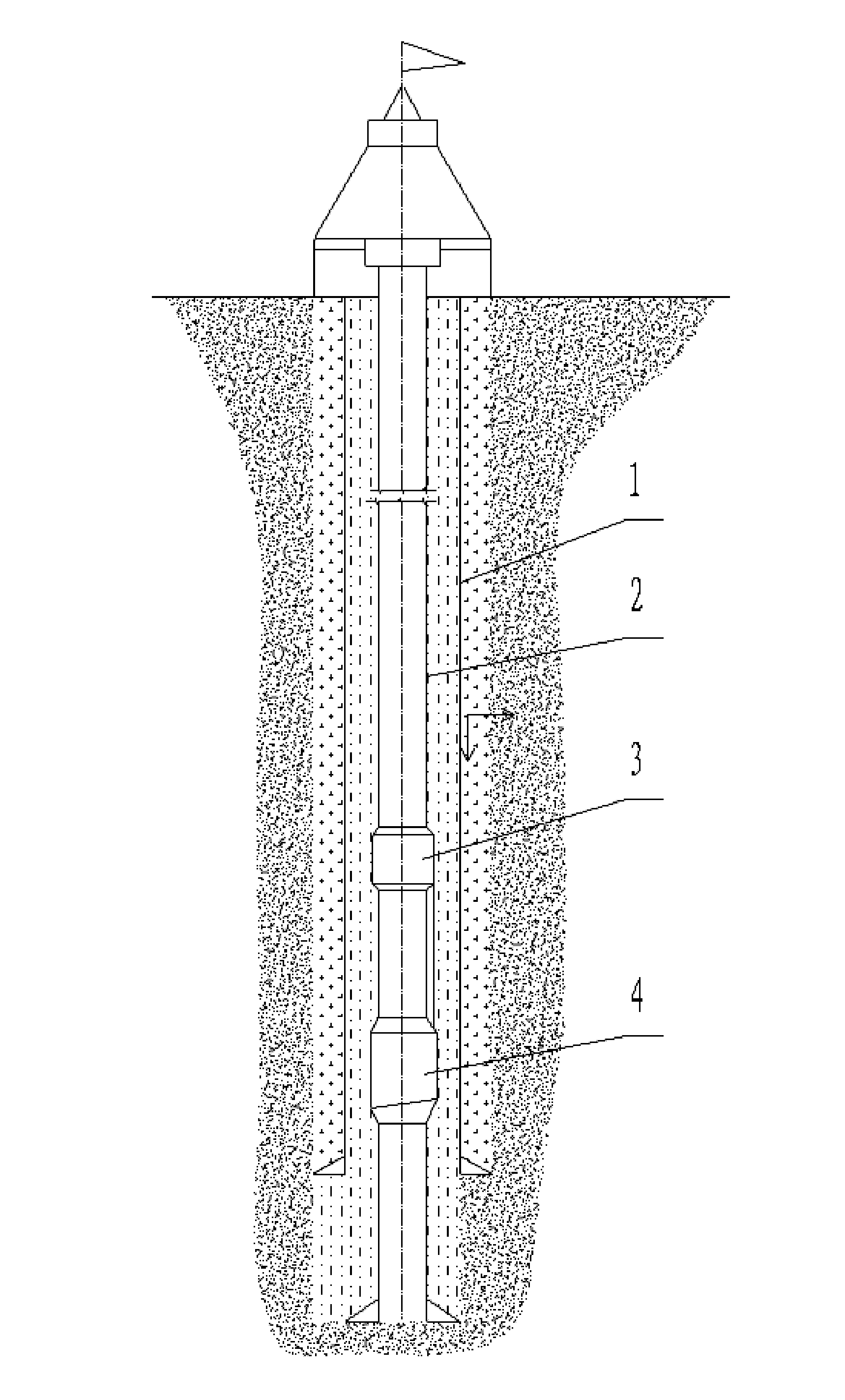

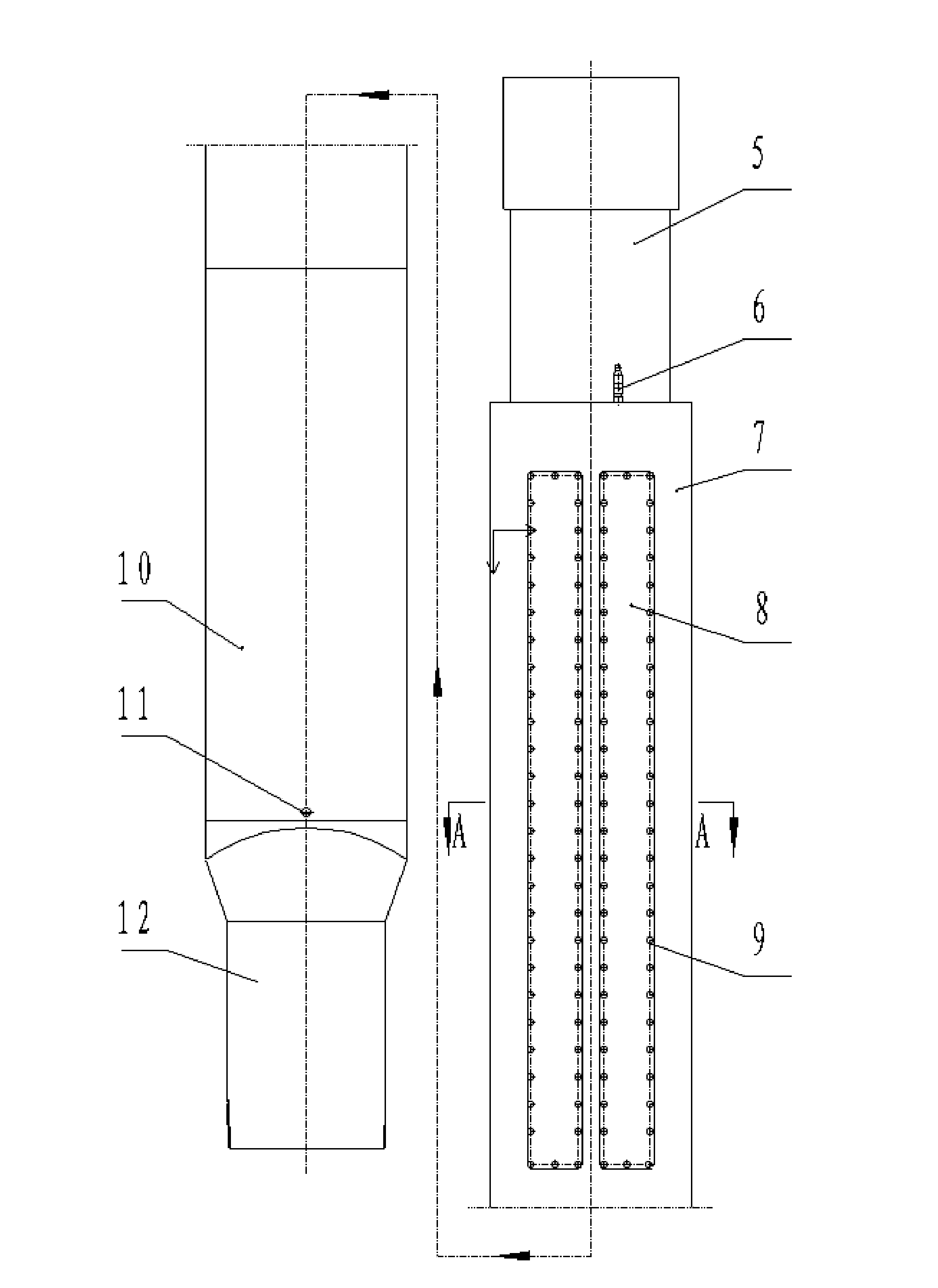

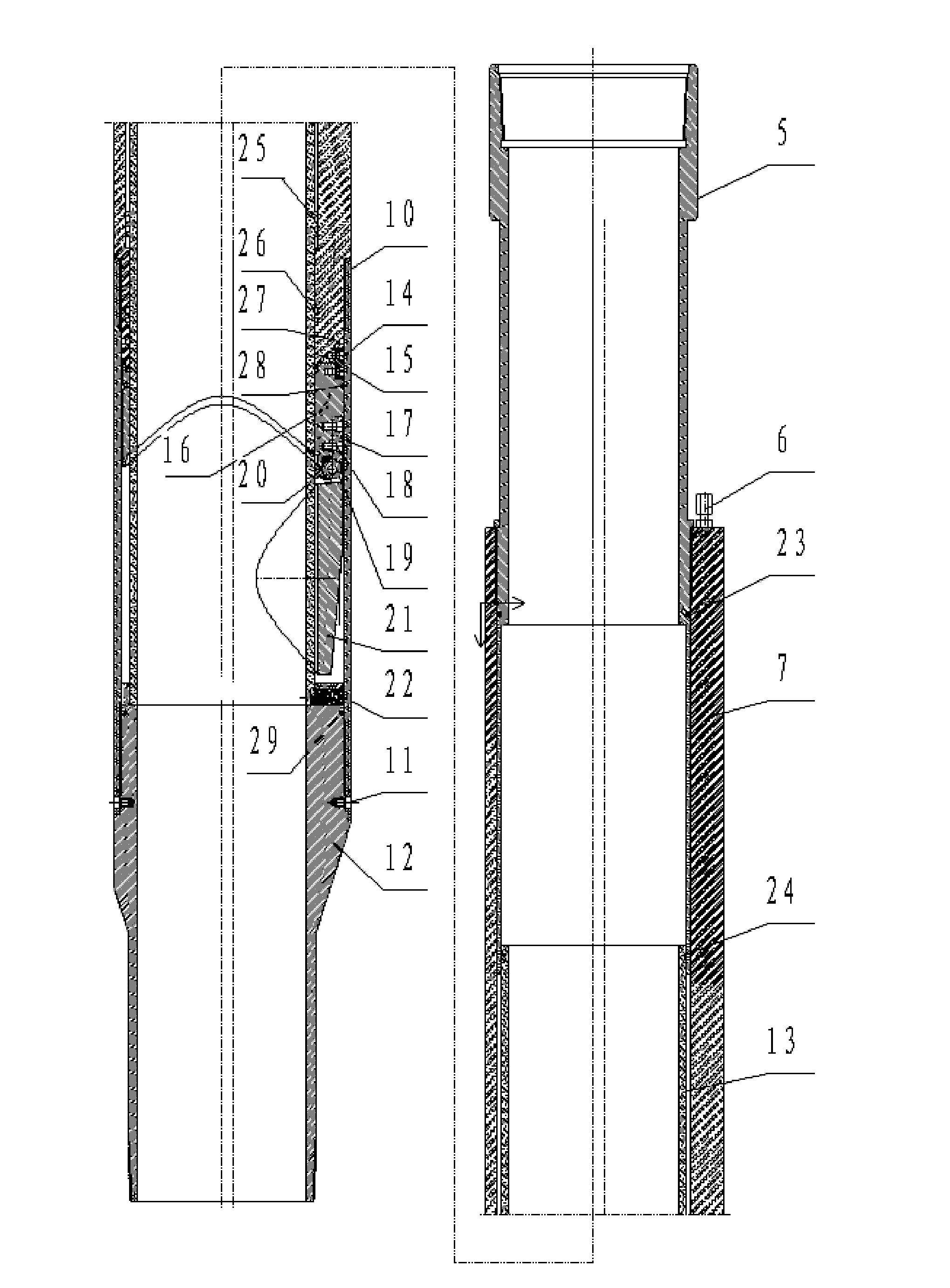

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, an automatic control casing valve, the casing valve is connected with the technical casing 2 in the downhole to form a casing string, and its depth can be located within the depth of the surface casing 1 or outside the depth of the surface casing 1 anywhere; the sleeve valve is composed of a non-magnetic sleeve short-connection assembly 3 and a sleeve valve main assembly 4, the non-magnetic sleeve short-connection assembly 3 is arranged on the sleeve valve main body assembly 4 and passed through the technical The bushing 2 is connected with the cable; the bushing valve main assembly 4 includes the bushing joint nipple 5, the eccentric outer cylinder 7, the connecting sleeve 10 and the lower eccentric joint 12, the bushing joint nipple 5, the eccentric outer cylinder 7, the connection The sleeve 10 and the lower eccentric joint 12 are screwed sequentially from top to bottom. A pist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com