Speed changer of vortex cloud rod engine

A main transmission and action technology, applied in the direction of mechanical equipment, transmission device control, portable lifting device, etc., can solve the problems of large volume, engine energy consumption, strong control force, etc., and achieve the effect of flexible shift operation and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

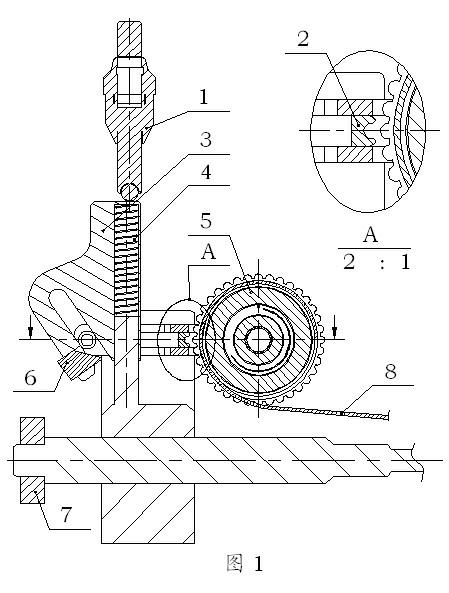

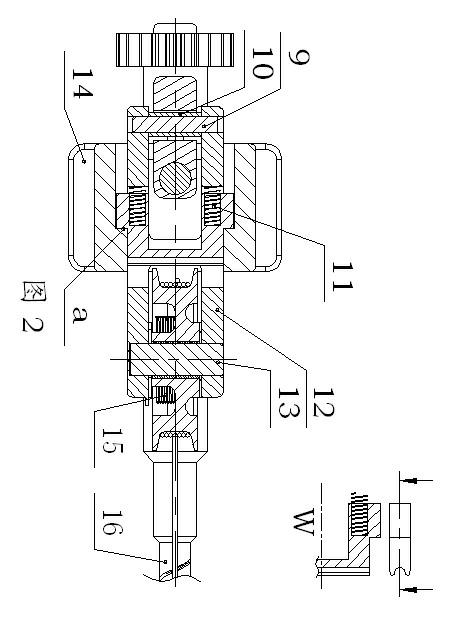

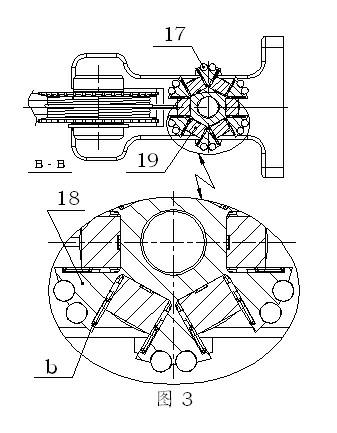

[0009] The rotary cloud rod engine transmission can be installed on the input shaft and output shaft of the engine to achieve double-action linkage effect, the magnetic flux control system can be controlled in parallel, and the number of gears is determined by the manufacturer according to the demand. All stages of variable speed gear discs are assembled with six groups of (32) spring spline teeth and they operate as a whole in the neutral zone. (30) Bearing ring is assembled with (29) flower shaft, (30) Bearing ring and all levels of variable speed gear discs are used for motion positioning, and the distance size of each gear disc of Baote is constant. (32) The dynamic positioning (v) motion trajectory line of the spring spline tooth is matched with the ring surface of (v1). (32) spring spline teeth and (28) roller spline teeth all operate according to the positioning of (30) bearing ring components. All levels of variable speed gears, (30) bearing rings, (32) spring spline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com