Design method for integrated stress, acceleration and service life testing profile of astronautic drive component

An accelerated life test and comprehensive stress technology, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc. There are issues such as the design method of aerospace drive components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

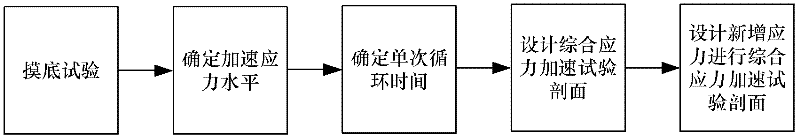

Method used

Image

Examples

Embodiment

[0046] Adopt the method of the present invention to the accelerated life test profile design of a certain type of solid lubricating bearing as follows:

[0047] Firstly, analyze the working environment and the stress of the solid lubricated bearing, and select the acceleration stress. Solid lubricated bearings are a basic aerospace drive component and are widely used in various instruments and mechanisms of space vehicles. The environmental stresses suffered by solid lubricated bearings mainly include temperature, radiation, etc., and the main working stresses include rotational speed, radial load, axial load, etc.

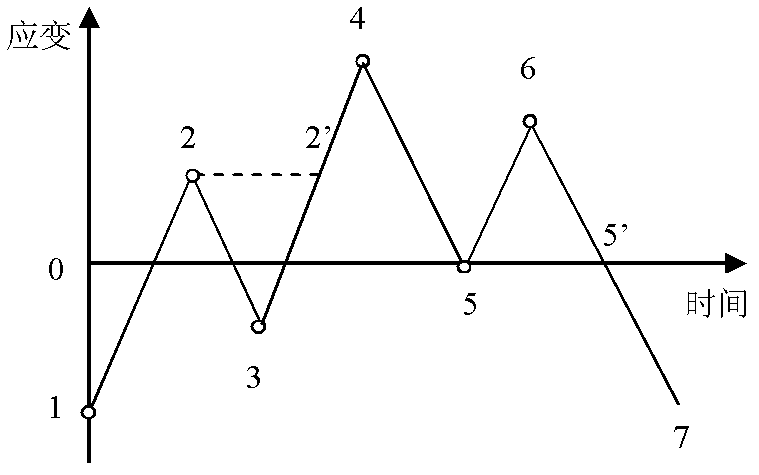

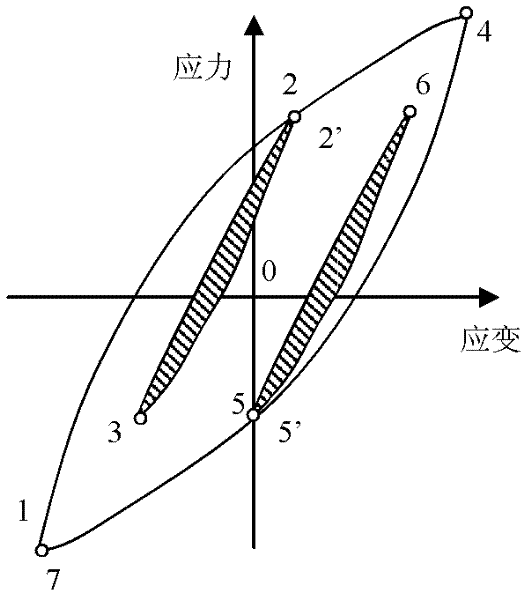

[0048] In actual work, the failure of solid lubricated bearings is mostly caused by poor lubrication or wear. The solid lubricating film is gradually worn out, and the lubricating film is destroyed, resulting in increased bearing torque or vibration, which eventually leads to failure. In the accelerated life test of solid lubricated bearings, the rotational spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com