Device and method for detecting drilling tool well head magnetic flux

A detection device, a technology of magnetic flux, applied in the direction of material magnetic variables, etc., can solve the problem of ineffective detection of changes in the cross-sectional area of drilling tools, and achieve the effect of a simple detection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

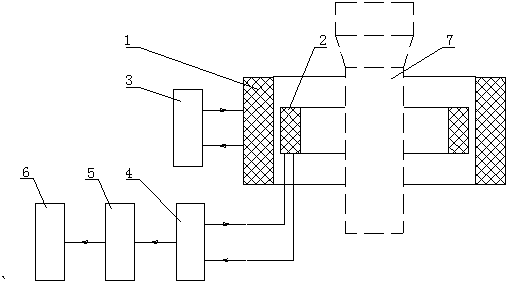

[0038] Refer to the attached figure 1 , The invention discloses a drilling tool wellhead magnetic flux detection device, which includes a current pulse generator, a primary coil, a secondary coil, an instrument amplifier circuit, a filter circuit, an A / D conversion and a host computer. The primary coil is on the outside and provides a pulse magnetic field for the drilling tool, and the pulse current generator provides pulse current for the primary coil. The secondary coil is installed inside the primary coil, and the wires of the secondary coil are connected with the instrument amplifying circuit. The instrument amplifier circuit, filter and A / D converter form a signal conditioning circuit, the secondary coil wire is connected to the instrument amplifier circuit, the instrument amplifier circuit is connected to the filter circuit, the filter circuit is connected to the A / D converter, and the A / D The converter is connected with the host computer.

[0039] At the same time, m...

Embodiment 2

[0045] The drilling tool wellhead magnetic flux detection method provided by the present invention is characterized in that the steps include:

[0046] Step 1: Hold the automatic slip card under the drill string collar, and then hoist it in the turntable;

[0047] Step 2: Install the detection device on the automatic slips;

[0048] Step 3: Provide pulse current to the primary coil through the current pulse generator of the detection device;

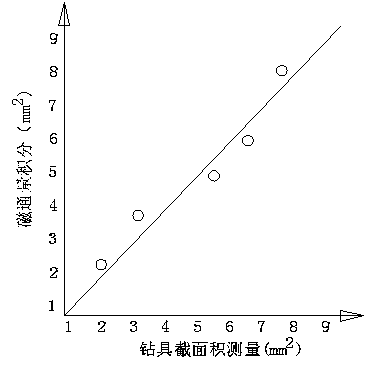

[0049] Step 4: Use the secondary coil to obtain the wear and corrosion of the inner and outer surfaces of the drilling tool; when the primary coil is energized, an instantaneous current will be generated in the secondary coil to obtain an instantaneous voltage. The current intensity and voltage generated by electromagnetic induction depend on The magnetic permeability and cross-sectional area of the drilling tool material, the severe wear or corrosion of the internal and external surfaces of the drilling tool will cause the cross-sect...

Embodiment 3

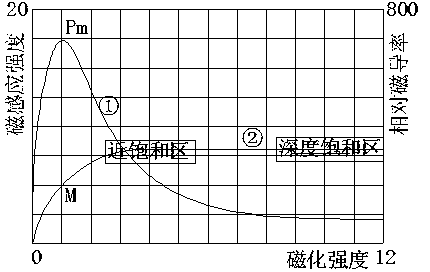

[0058] The best implementation of the detection method is to control the pulse current of the primary coil to control the magnetic field strength, so as to control the magnetic permeability of the drilling tool to the maximum value. Specifically: the control of sensor parameters. The magnetic flux is equal to the product of the magnetic permeability and the magnetic field strength. The cross-sectional area of the drilling tool changes due to wear and corrosion, and the magnetic field strength that can be sensed changes. Therefore, an electromagnetic sensor, that is, a secondary coil, can be used to measure the change in cross-sectional area. In order to enable the secondary coil to sense the change of the magnetic flux of the drilling tool, the primary coil is required to provide a sufficiently strong magnetic field. Usually, the stronger the magnetization, the larger the volume of the primary coil. When the primary coil applies a magnetic field to the drilling tool, only wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com