Fruit and vegetable logistics fresh-keeping transportation control system

A control system, fruit and vegetable preservation technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of difficult to measure accurately, difficult to achieve scheduling and control, unable to guarantee the quality of fruits and vegetables, etc., to ensure quality, improve The effect of the level of automation and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

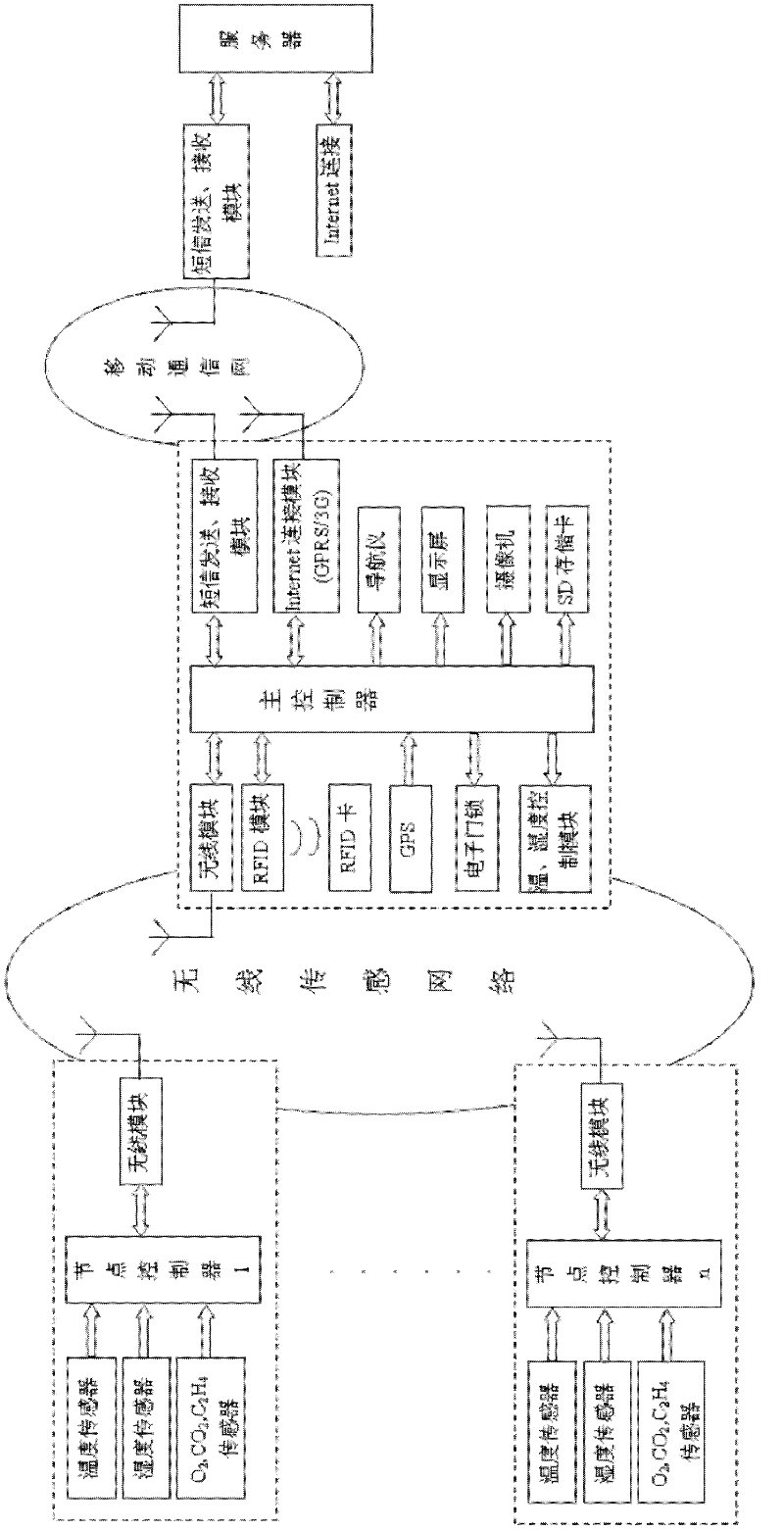

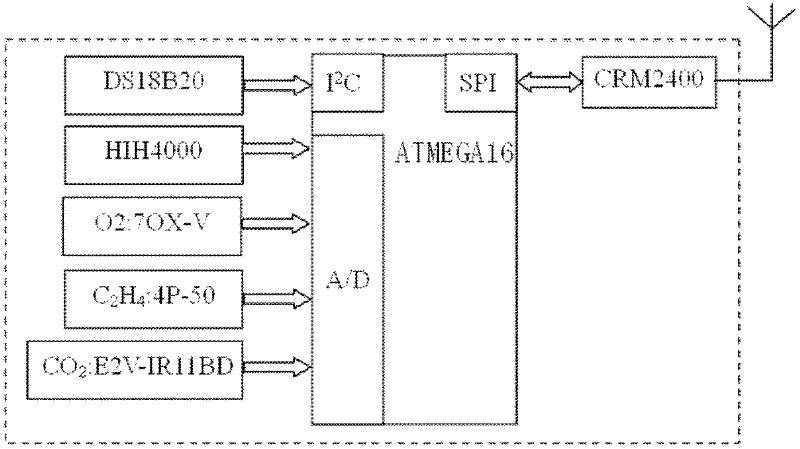

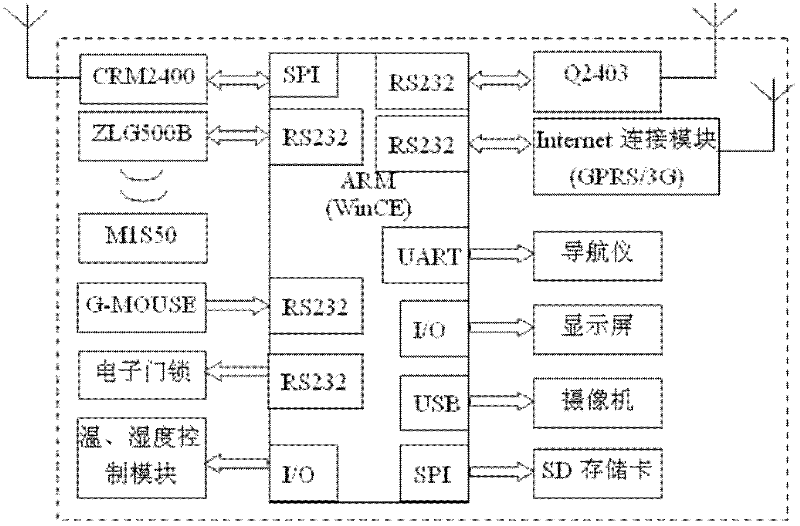

[0024] A fruit and vegetable logistics fresh-keeping transportation control system, such as figure 1 As shown, it includes a node controller, a main controller and a fruit and vegetable fresh-keeping transportation monitoring server. The main controller is connected with several node controllers through a wireless sensor network, and the main controller is connected with a fruit and vegetable fresh-keeping transportation monitoring server through a mobile communication network. together. The node controller collects temperature, humidity, oxygen, ethylene, carbon dioxide and other data in the fruit and vegetable fresh-keeping transport vehicle through various sensors, and transmits the above data to the main controller, and then the main controller transmits it to the fruit and vegetable fresh-keeping transport monitoring server, and the fruit and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com