Wet-process etching cleaning device and wet-process etching cleaning method

A technology of wet etching and cleaning equipment, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem of not being able to form accurate graphics, and achieve the effect of improving the uniformity between chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

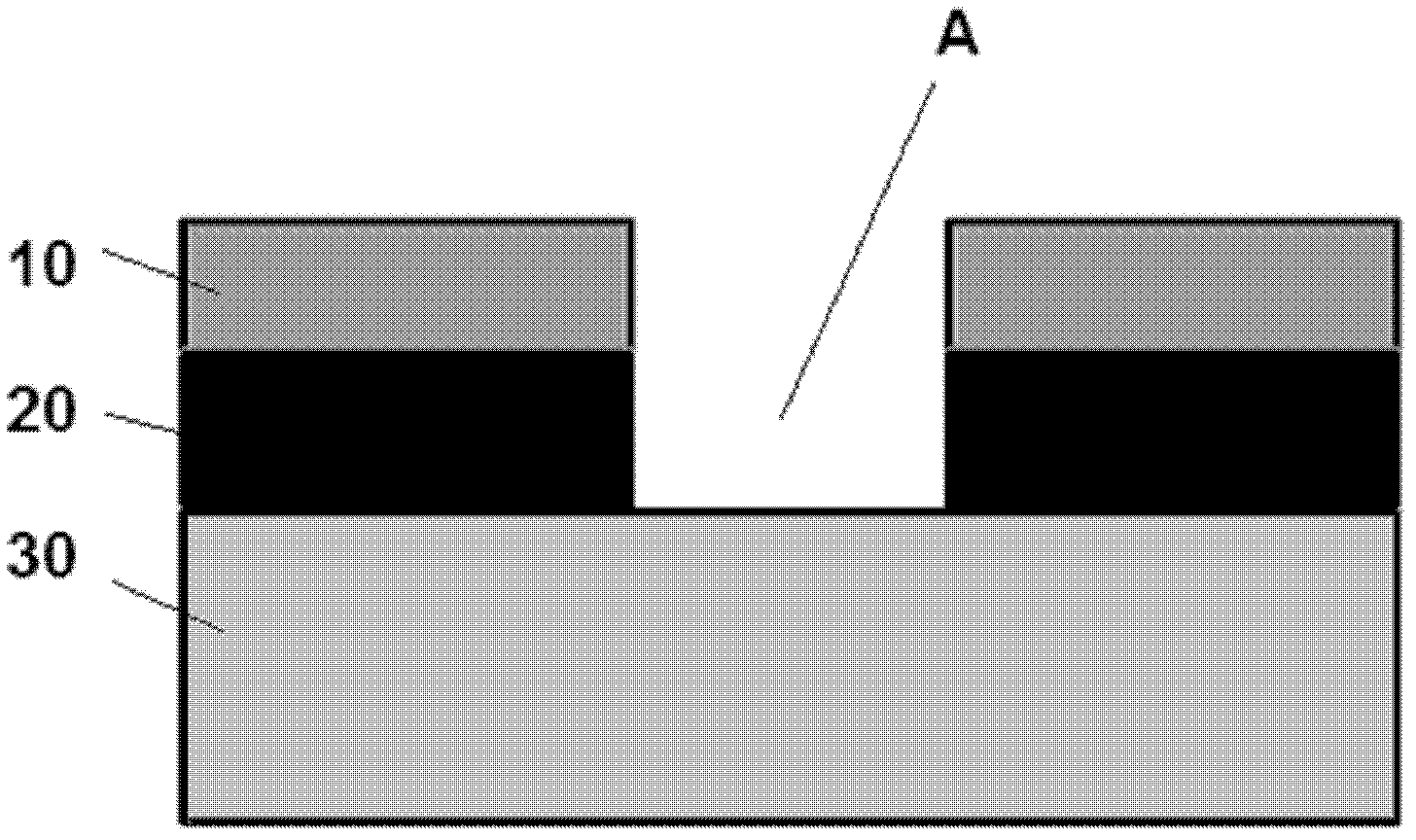

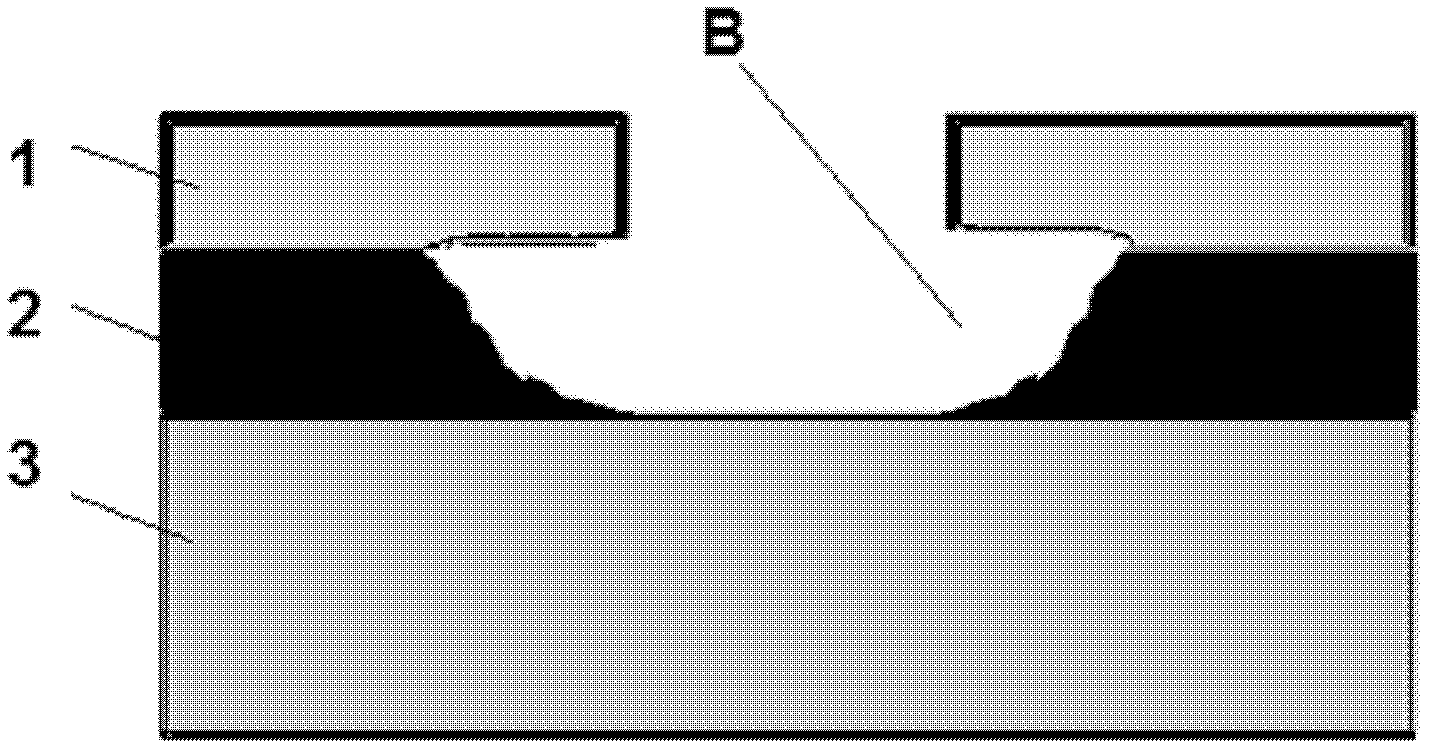

[0023] In wet etch cleaning equipment, chemical baths are used in which to wet etch or pre-clean wafers. The chemical tank liquid diverter plate is used to change the characteristics of the liquid flow in the chemical tank.

[0024] The uniformity of etchant (such as hydrofluoric acid) and etching buffer on the wet etching rate of the etched layer (such as silicon dioxide film) is greatly affected by the design of the chemical tank liquid distribution plate.

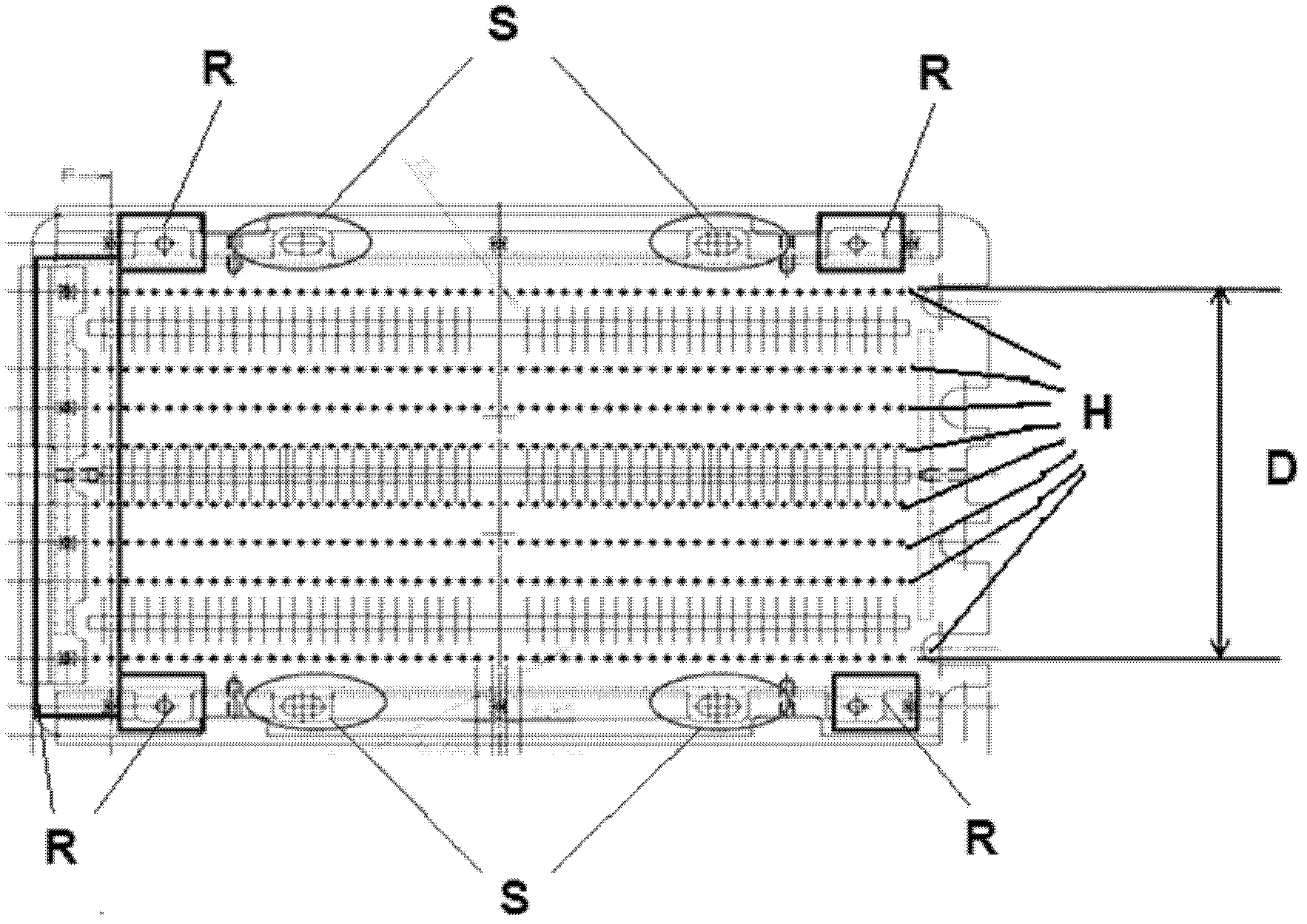

[0025] image 3 A structural diagram of a chemical tank liquid distribution plate in a wet etching cleaning device according to an embodiment of the present invention is shown.

[0026] Such as image 3 As mentioned above, the chemical tank liquid distribution plate in the wet etching c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com