Method for prolonging service life of electroformed microfluidic nickel die and electroformed microfluidic nickel die

An electroforming mold and microfluidic technology, applied in electroforming, electrolysis process, etc., can solve the problems of pattern deformation, polishing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

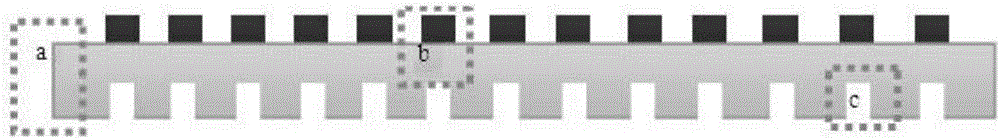

[0041] A method for preparing an electroformed microfluidic nickel mold, the steps are as follows:

[0042] 1. According to the pattern designed by microfluidics, design and prepare a negative mask plate for future use.

[0043] 2. Choose glass as the substrate, and after cleaning, spin-coat negative photoresist on the glass substrate. The photoresist used is SU-8 3050 photoresist. The specific spin-coating method is: The glass is fixed on the rotary table, and the glue is uniformed first; then the glue is brushed.

[0044] 3. First perform soft drying and exposure treatment; then perform intermediate drying and development treatment to obtain photoresist patterns.

[0045] 4. Perform magnetron sputtering nickel on the photoresist pattern to obtain a photoresist pattern with metallization on the surface.

[0046] 5. Put the metallized photoresist pattern into the nickel-containing electroforming solution, and use it as a cathode for electroforming for 72 hours to obtain a ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com