Contact sensor for lawns

A contact sensor, sensor unit technology, applied in the direction of instruments, lawn mowers, cutters, etc., can solve the problems of dust pollution, easy aging and wear, and inductive devices and sensors are difficult to work in a long-term environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

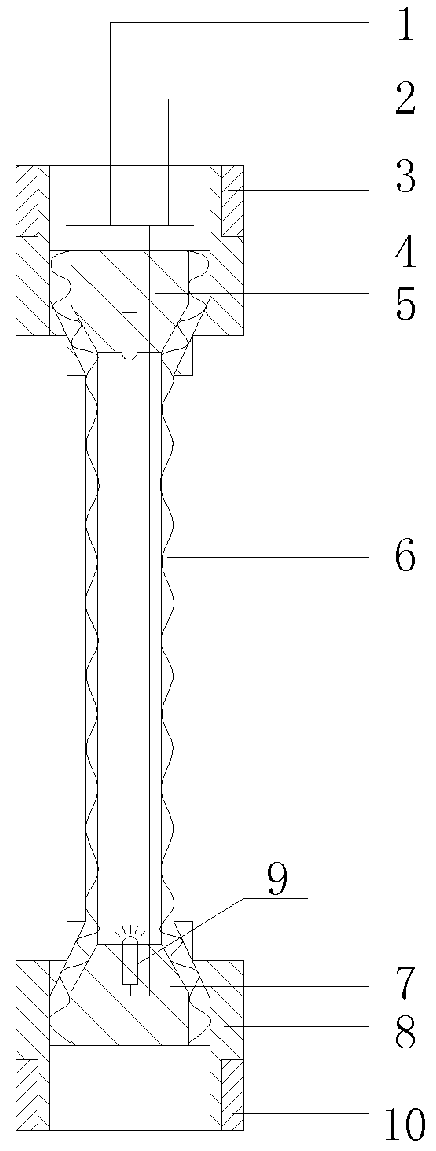

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

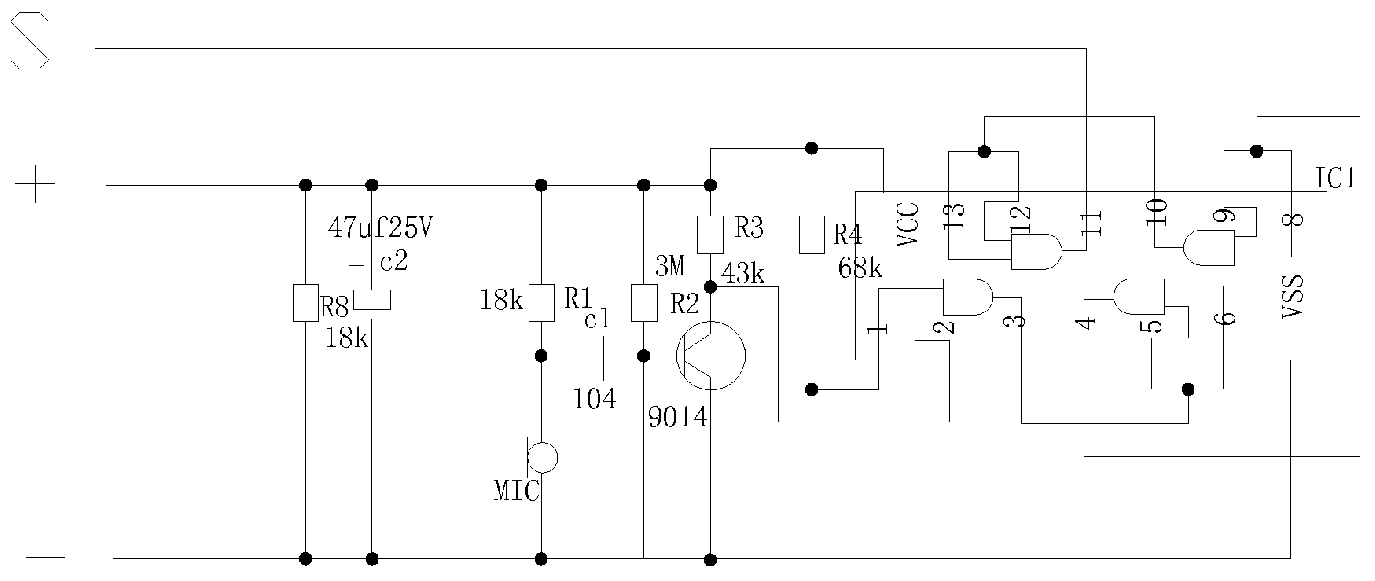

[0033] The technical solution of the present invention is to use an acoustic-electric transducer to receive the acoustic signal generated when it touches the grass. The acoustic-electric transducer is installed in a closed elastic casing, and the contact end of the casing has a certain height from the ground. . When the contact end of the sensor housing touches the grass, the acoustic-electric converter receives the sound wave generated when the object touches and converts it into weak electric energy, and then outputs a level signal that meets the requirements of the digital signal after being amplified by the amplifier circuit. This is used to perceive the grass and the length of the grass in contact.

[0034] Such as figure 1 , 2 As shown, the brush contact sensor of the present invention includes an upper housing and a lower housing communicated by an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com