Single-sided two-dimensional driving digital microfluidic chip based on electrowetting

A digital microfluidic and electrowetting technology, used in laboratory containers, laboratory utensils, chemical instruments and methods, etc., can solve the problem of doubling the complexity of the driving circuit, and the driving ability is not as good as the single-sided grounding of the upper plate. structure and other issues, to achieve the effect of high throughput and parallel control capability, simple control, and good degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

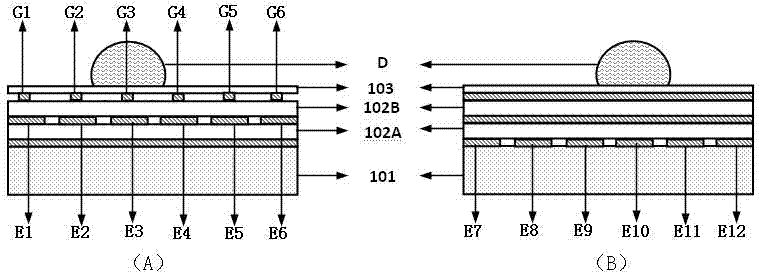

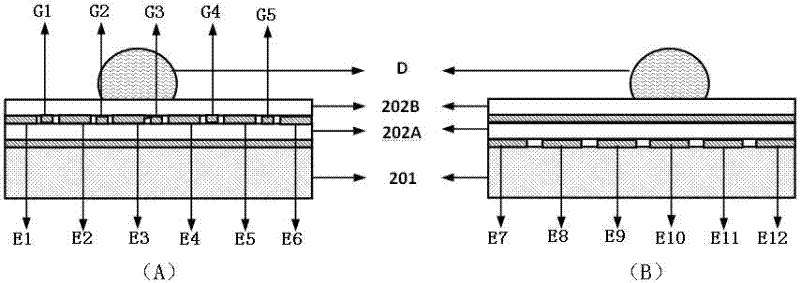

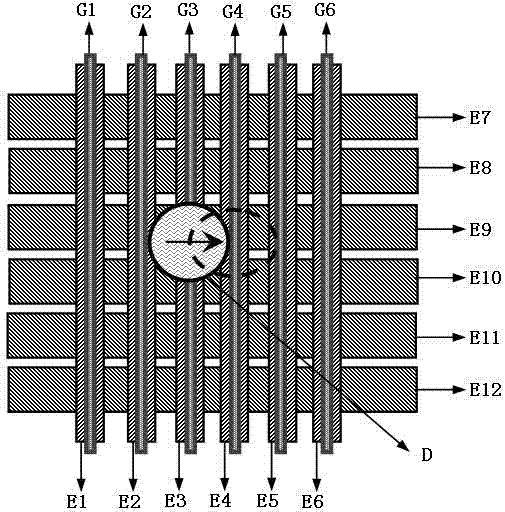

[0025] The chip structure of the present invention is as figure 1 (A), figure 1 As shown in (B), there are first electrode layers (driving electrodes) E7-E12 on the substrate 101. It should be noted that the material used as the substrate is not fixed, as long as it is insulated, such as quartz, glass, insulated silicon wafer, etc.; and the electrode (including the ground electrode described below) can be composed of any material, and the electrode shape is For the above-mentioned "strip shape", the size and spacing of the electrodes and the number of specific electrodes are not limited. This specification only takes a certain number and specifications of electrodes as an example. There is a first dielectric layer 102A on the first electrode layer, and second electrode layers E1-E6 are arranged on it; and a second dielectric layer 102B is arranged on the second electrode layer E1-E6. In each electrode layer, all the individual electrodes are arranged in parallel; the second ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com