Welding lift frame

A technology of lifting frame and supporting member, which is applied in the field of lifting frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

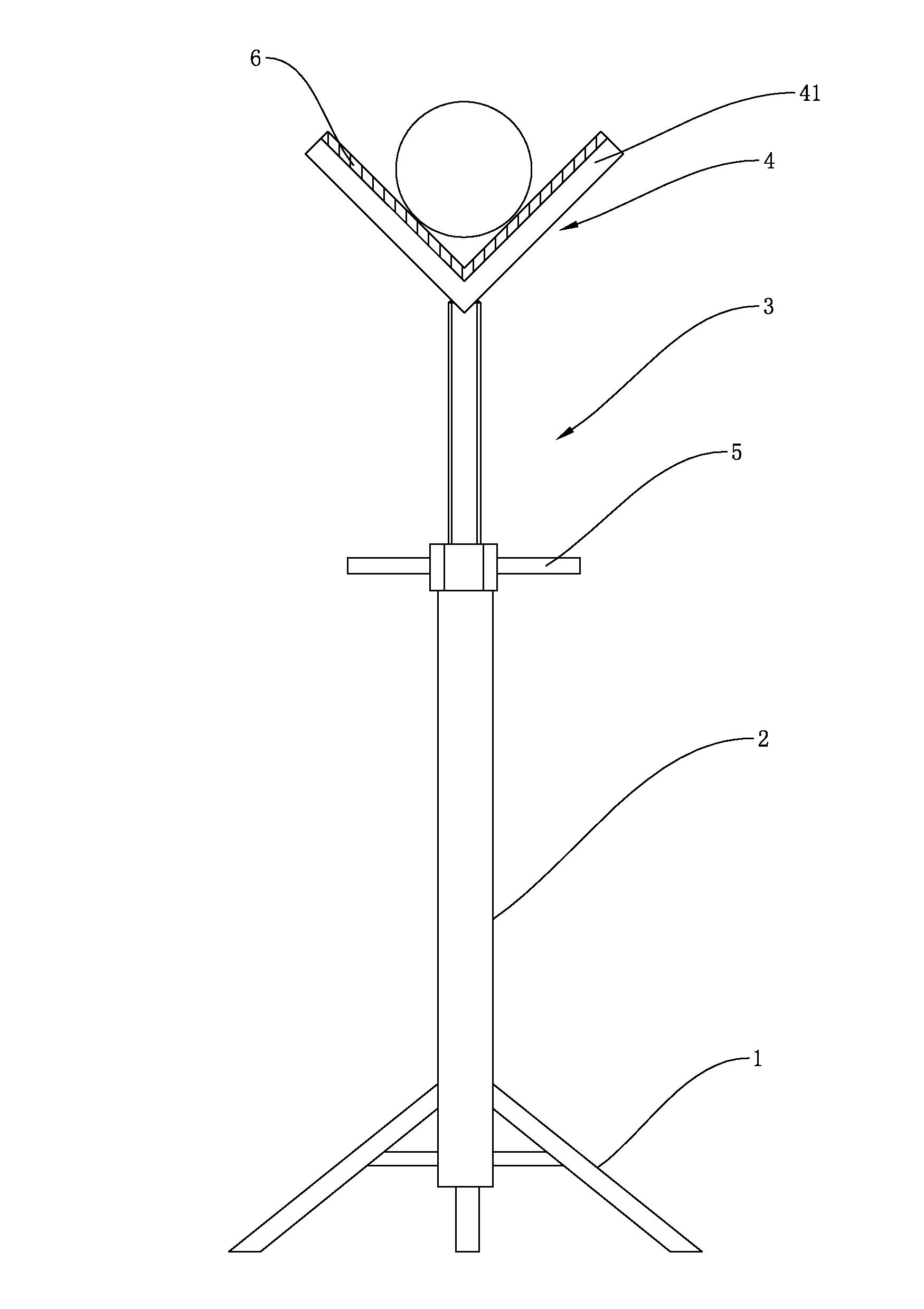

[0028] Such as figure 1 and Figure 4 As shown, a welding lifting frame includes a bracket 1, a sleeve 2 is installed on the upper end of the bracket 1, and a lead screw of a lead screw nut mechanism 3 is sleeved in the sleeve 2, and the lead screw of the lead screw nut mechanism 3 A support 4 is installed on the upper end of the bar. The support described in this embodiment is selected as a V-shaped support 4. The support surface of the support 4 is covered with a protective layer 6 to prevent the workpiece from being corroded by the support 4. In this implementation In the example, the protective layer 6 is a tetrafluoroethylene plate, the nut of the screw nut mechanism 3 is installed on the sleeve 2, and a wrench 5 is installed on the nut of the screw nut mechanism 3 . When the worker is welding, he can turn the wrench 5 to adjust the support member 4 to a suitable height as needed.

Embodiment 2

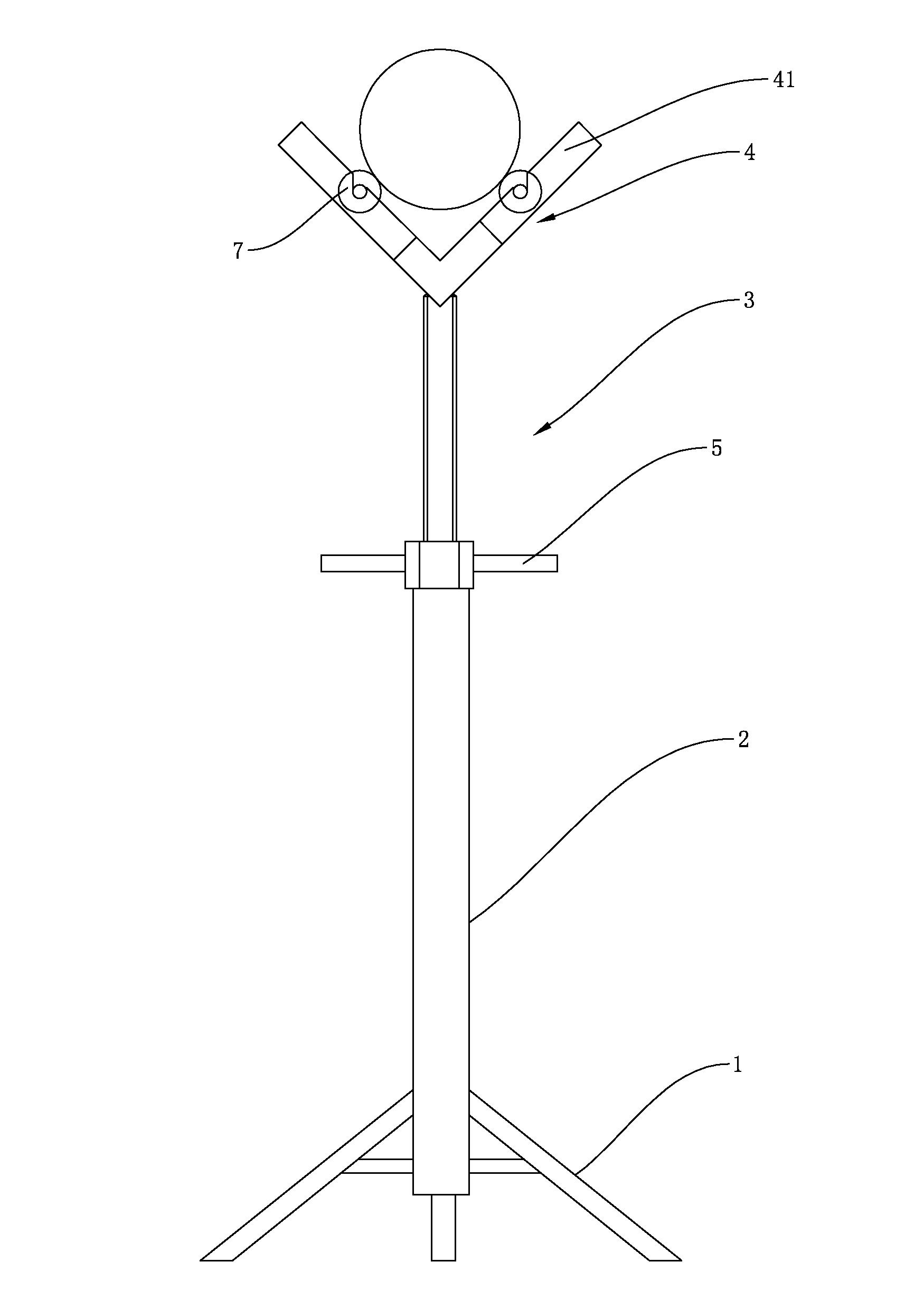

[0030] Such as figure 2 As shown, a welding lifting frame includes a bracket 1, a sleeve 2 is installed on the upper end of the bracket 1, a lead screw of a lead screw nut mechanism 3 is sleeved in the sleeve 2, and a nut of the lead screw nut mechanism 3 Installed on sleeve 2. A wrench 5 is installed on the nut of the lead screw nut mechanism 3, a V-shaped support 4 is installed on the upper end of the lead screw of the lead screw nut mechanism 3, and a V-shaped support 4 is installed on the two support plate parts 41 of the support 4 respectively. The support roller 7 is provided with at least one set of angularly symmetrical installation grooves on the support plate portion 41. In this embodiment, a set of angularly symmetrical installation grooves is provided, and the support roller shaft of the support roller 7 is inserted into the installation groove Inside. Determine the size of the diameter of the support roller 7 according to the pipe diameter of the workpiece to b...

Embodiment 3

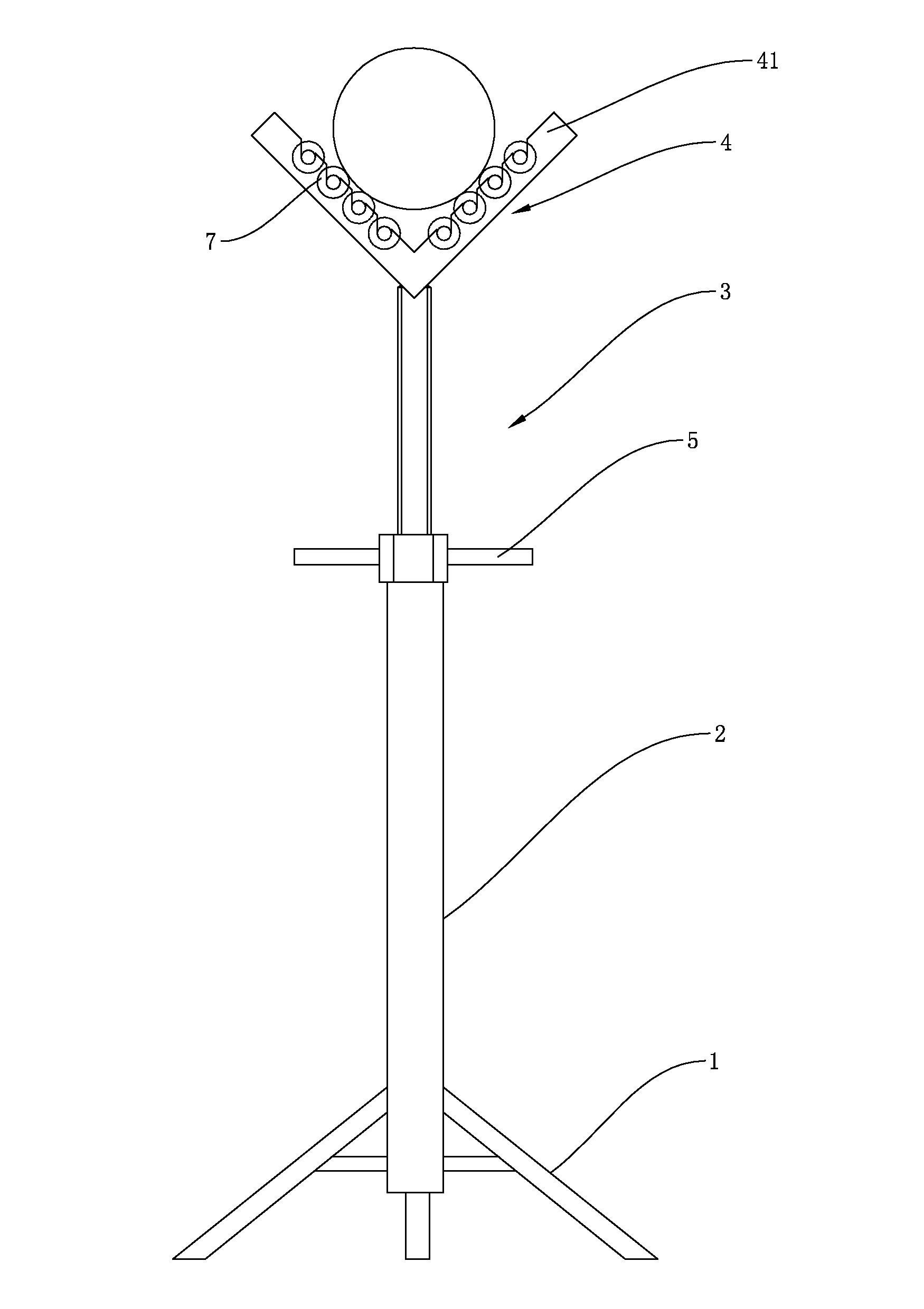

[0034] Such as image 3 As shown, a welding lifting frame includes a bracket 1, a sleeve 2 is installed on the upper end of the bracket 1, a lead screw of a lead screw nut mechanism 3 is sleeved in the sleeve 2, and a nut of the lead screw nut mechanism 3 Installed on the sleeve 2, a wrench 5 is installed on the nut of the lead screw nut mechanism 3, a V-shaped support 4 is installed on the upper end of the lead screw of the lead screw nut mechanism 3, and the two supports of the support 4 The support rollers 7 are respectively installed on the plate portion 41 . The support plate portion 41 is provided with at least one set of angularly symmetrical mounting grooves, and in this embodiment, four sets of angularly symmetrical mounting grooves are provided, and the supporting roller 7 of the supporting roller 7 is axially inserted into the mounting grooves. The installation method of the support roller 7 is detachable installation.

[0035] In the process of welding the workpi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com