Assembling and scraping device for square hole of spindle box

A spindle box and spindle technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as difficult to ensure scraping accuracy, low production efficiency, and workpiece damage, so as to save manpower, improve production efficiency, and eliminate workpieces. The effect of bruising or damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

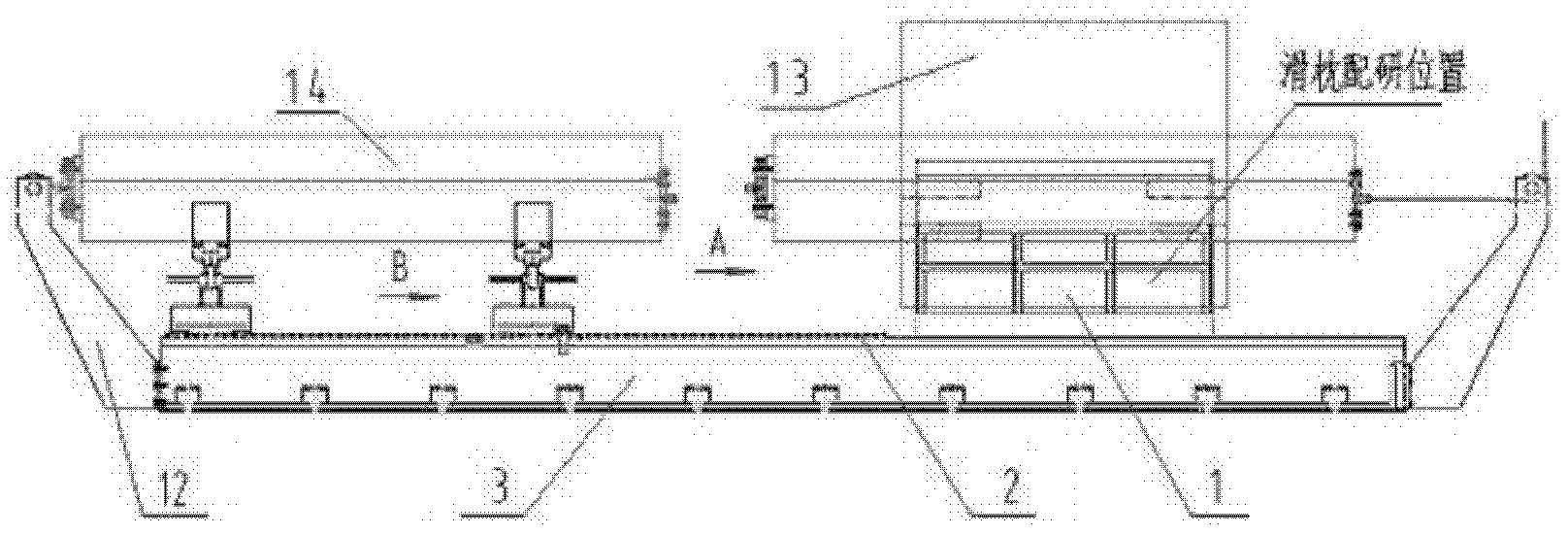

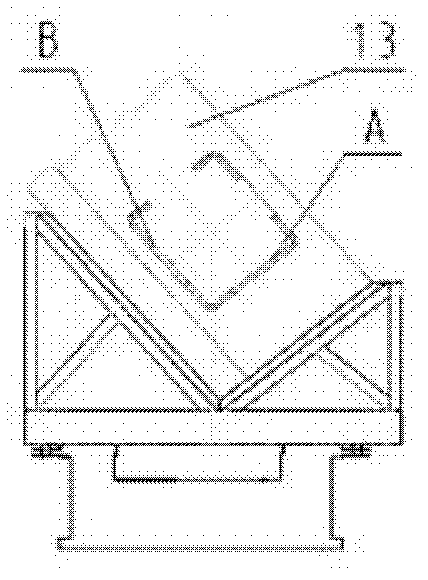

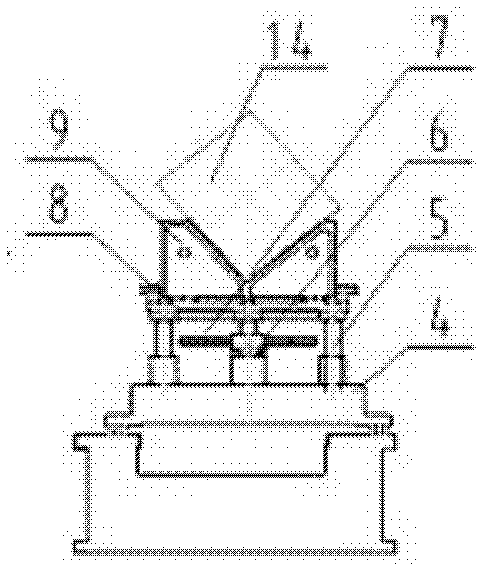

[0038] like Figure 1 to Figure 5 The structure of the present invention expressed is a square hole assembly scraping device for the spindle box, which is installed on the basic bed 3, and is used for assembly scraping and product assembly processing of the spindle box 13 and the ram part 14 of the CNC floor milling and boring machine; The basic bed 3 described above is provided with a precision linear guide rail 2 .

[0039] In order to solve the problems existing in the current known technology described in the background technology section of this specification and overcome its defects, and realize the invention purpose of impro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com