Piston reset tool for disc brake

A technology of disc brakes and pistons, applied in the manufacture of tools, hand-held tools, etc., can solve the problems of large differences in the thickness of the friction plate, cumbersome operation process, and difficulty in piston reset, and achieve overcoming blockage, convenient use, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

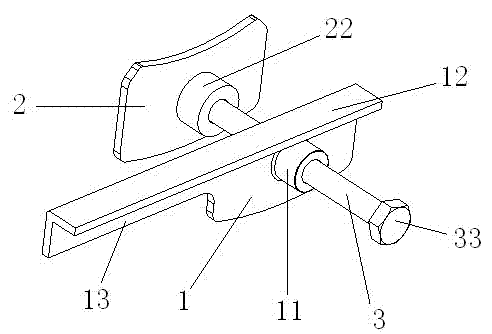

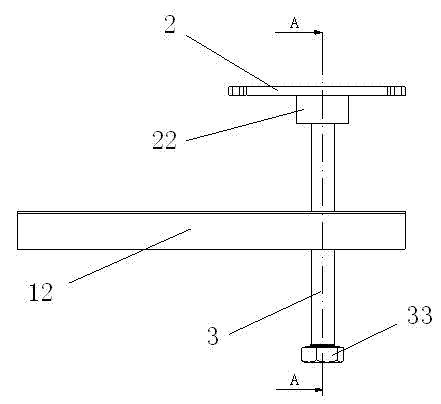

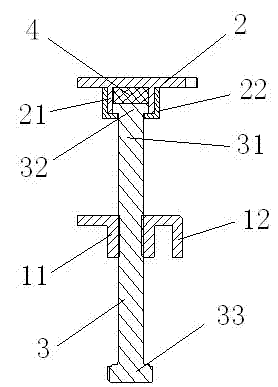

[0019] Such as figure 1 As shown, the outer push plate 1, the inner push plate 2 and the screw rod 3 of the disc brake piston reset tool of the present embodiment, wherein the outer push plate 1 is equipped with a threaded sleeve 11, and a threaded hole is arranged in the threaded sleeve 11; the outer push plate 1 has a horizontal fold 12 on the top surface, and an extended armrest 13 is provided on the side.

[0020] Such as figure 2 , 3 As shown, the side of the inner push plate 2 is provided with an annular limit seat 21, and the limit seat 21 is provided with an external thread, and a hollow locking cap 22 is installed through thread fit, and the locking cap 22 is far away from the inner push plate. The side of the screw rod is provided with a through hole; the pressing end 31 of the screw passes through the threaded hole of the threaded sleeve 11 and the through hole of the locking cap 22 in turn, and extends into the locking cap 22; the end of the pressing end 31 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com