Clamping device for rapidly replacing cutting blades

A technology for cutting blades and clamping devices, used in metal processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

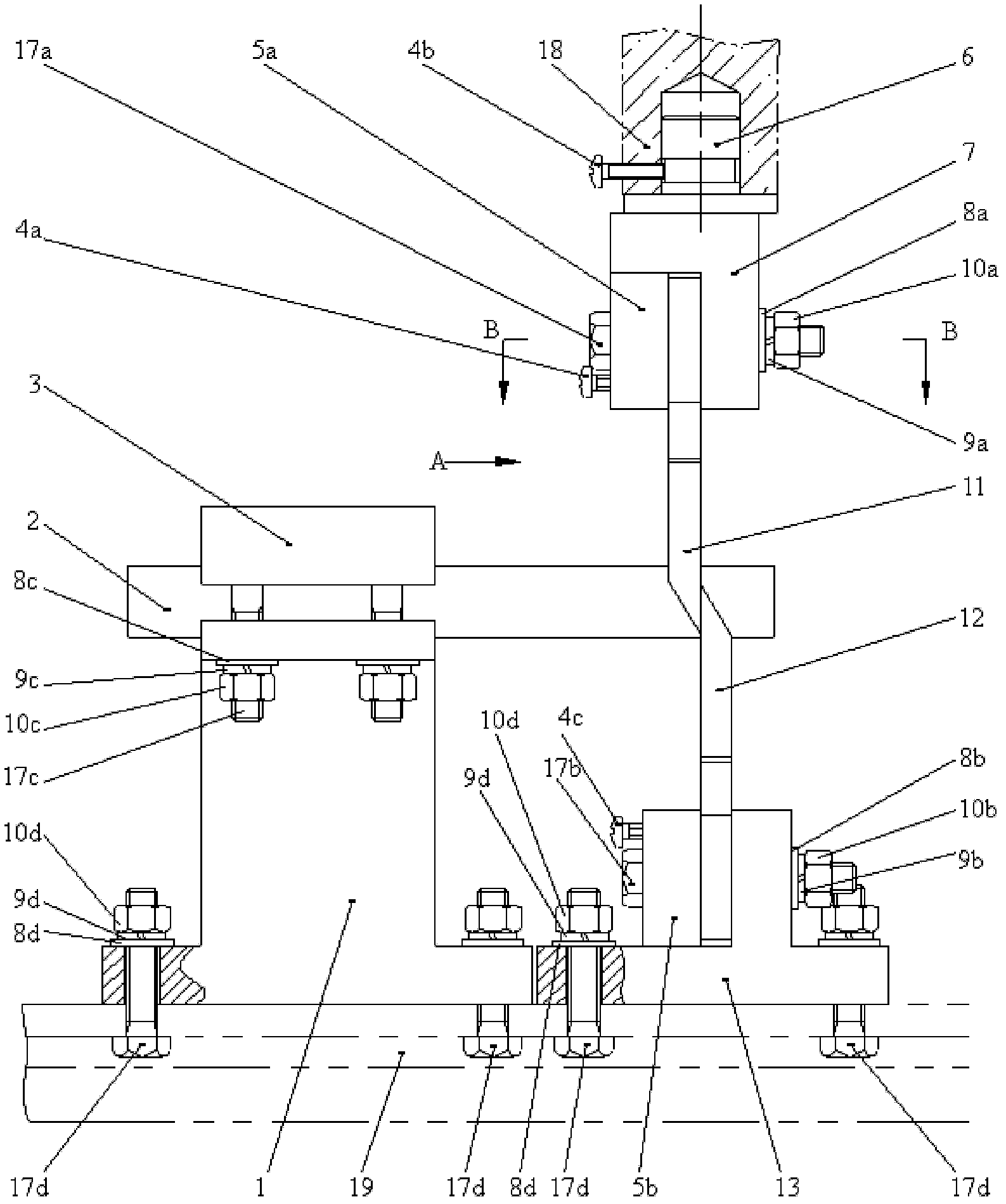

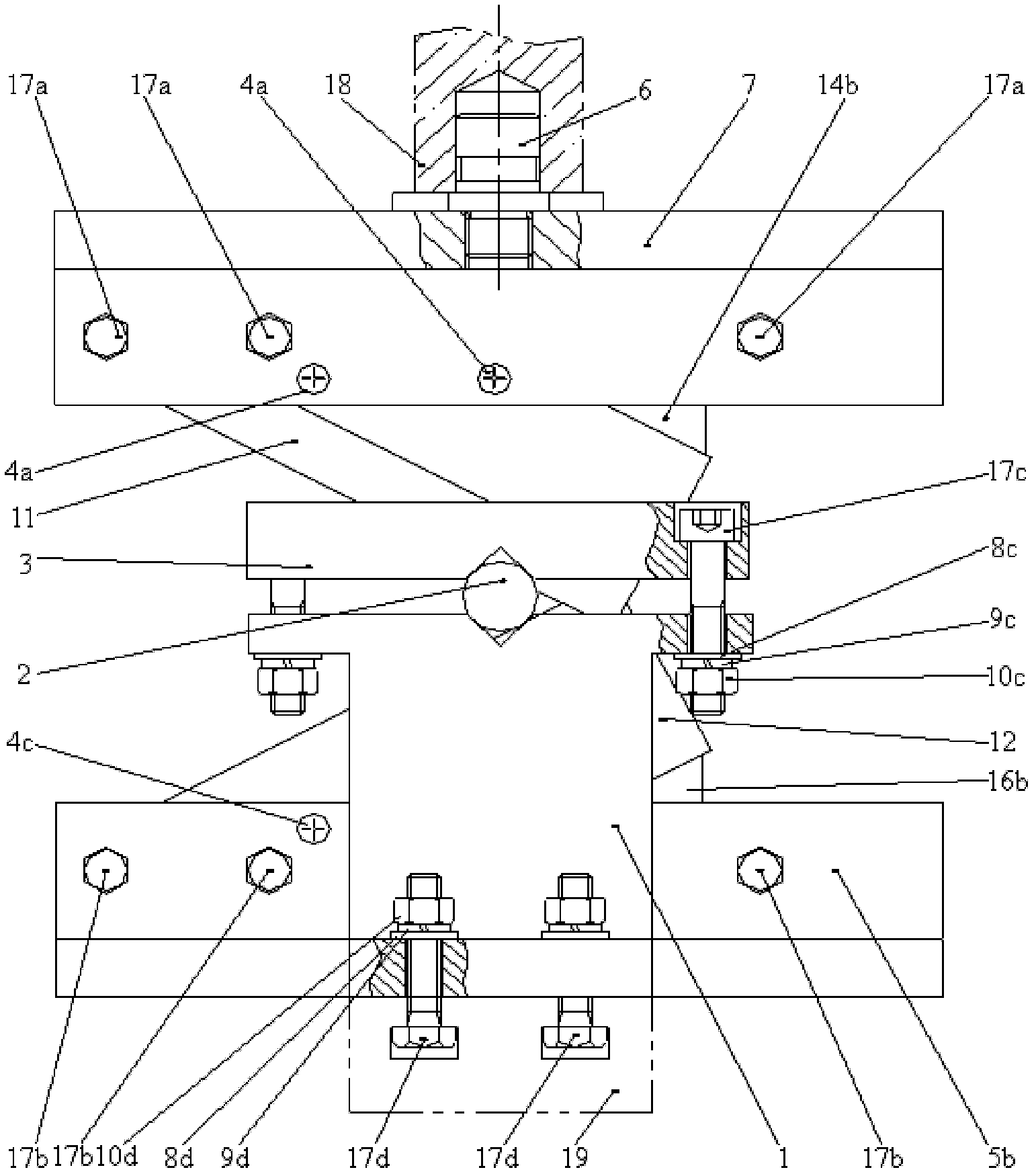

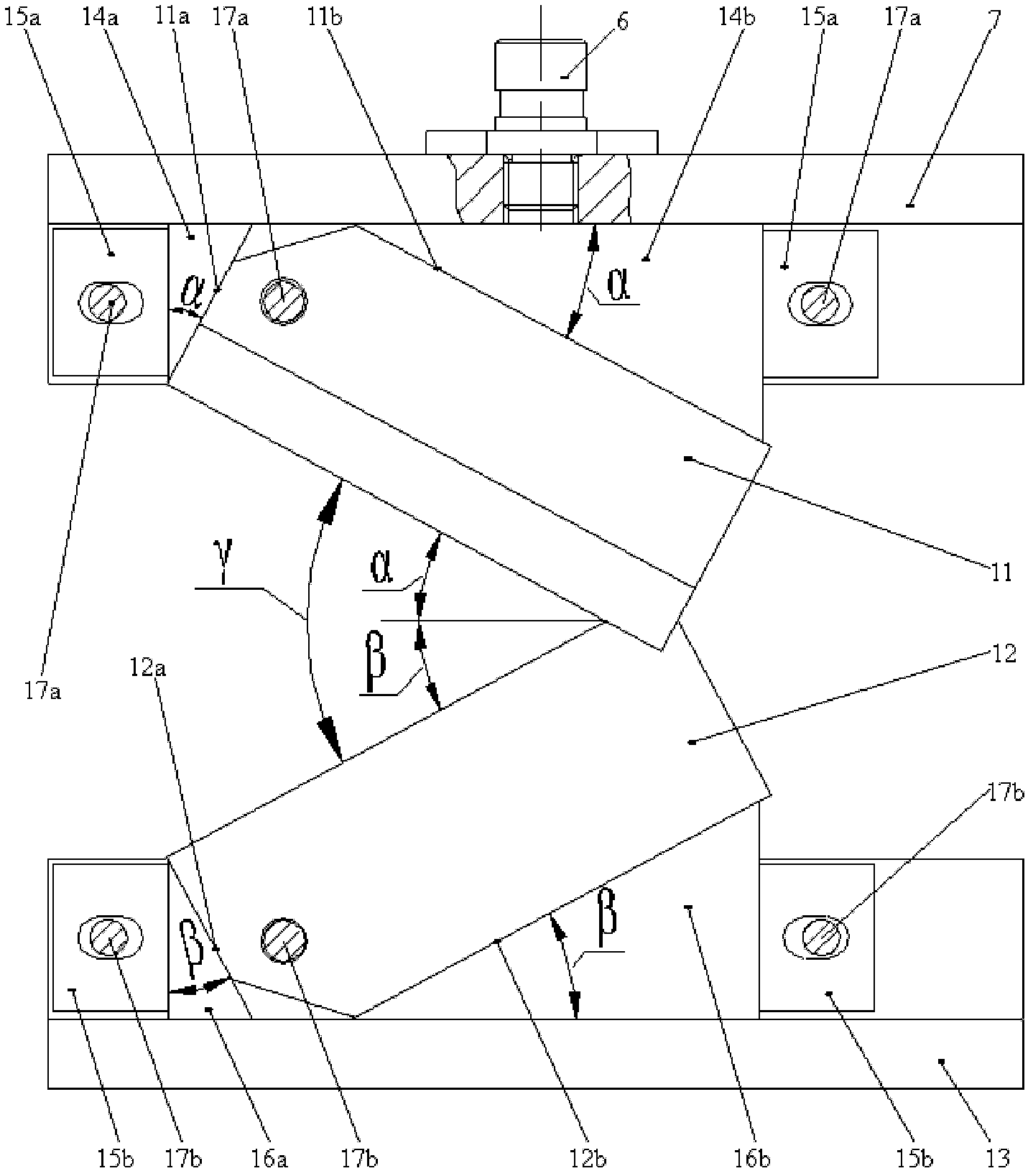

[0016] The accompanying drawing is an embodiment of the present invention, but is not used to limit the scope of the present invention.

[0017] The invention relates to a clamping device capable of rapidly replacing cutting blades, which is composed of a sample fixing mechanism, a moving knife adjusting mechanism and a fixed knife adjusting mechanism. The specific implementation method of the present invention will be introduced below in conjunction with the accompanying drawings.

[0018] In the figure, the sample fixing mechanism is connected to the T-shaped slot (19) on the worktable of the universal testing machine through bolts d (17d), nuts d (10d), etc.; the moving knife adjustment mechanism is connected to the universal testing machine through the positioning pin (6) The connecting shaft (18) on the machine is connected, the threaded end of the positioning pin (6) is connected with the moving knife fixed block (7), and the other end matches the pin hole on the connect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com