Welding mechanism of position punch fixture glue piece

A technology for positioning punching and plastic parts, which is applied in the mechanical field and can solve problems such as multiple errors in material placement, inaccurate product positioning, and dislocation of plastic parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

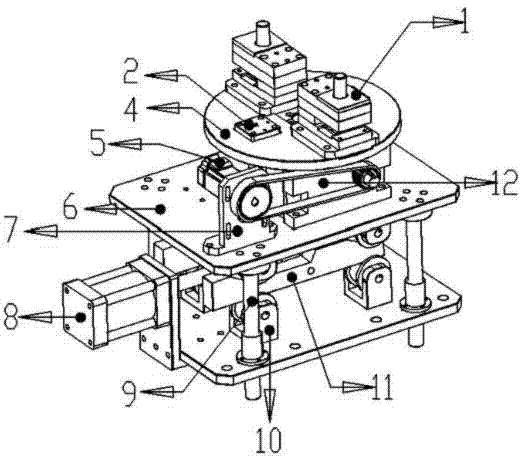

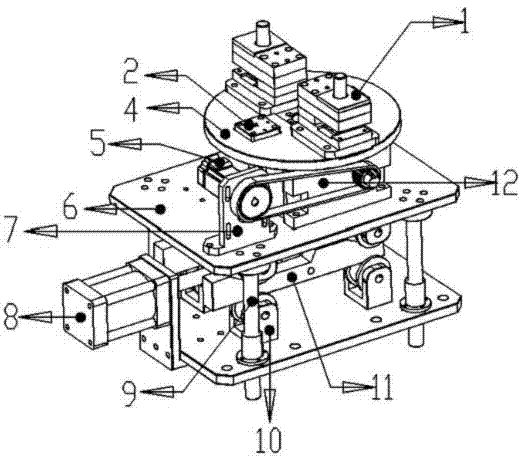

[0021] A welding mechanism for positioning punching tooling rubber parts of the present invention includes such as figure 1 As shown, it consists of metal stamping die 1, plastic bottom mold 2, plastic heat sealing mold 3, turntable 4, low-power speed-regulating motor 5, chassis 6, low-power speed-regulating motor mounting plate 7, chassis rising cylinder 8, and chassis rising The adhesive and tape fusion mechanism composed of guide rod 9, ascending pulley 10, ascending slider 11 and divider 12,

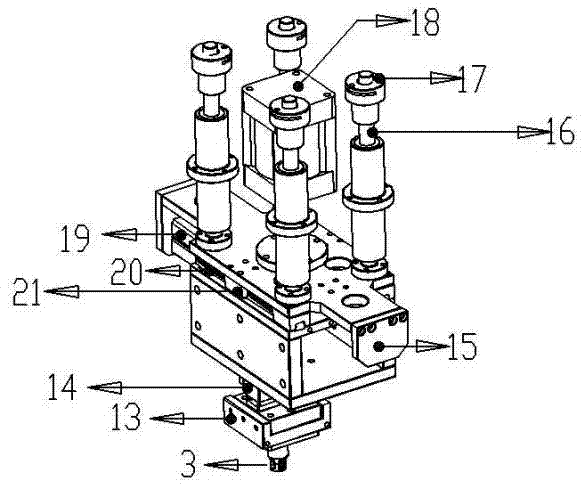

[0022] and as figure 2 The upper die heating plate 13, the upper die drive cylinder 14, the limit baffle plate 15, the punching guide rod 16, the punching limit nut 17, the punching drive cylinder 18, the die change cylinder 19, and the linear slide rail 20 are shown. and the impact mechanism composed of linear slider 21,

[0023] The impact mechanism is placed above the rubber and tape fusion mechanism. When the metal stamping die is working, the rubber and tape fusion m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com