Automatic rectifying device in strip steel rolling device

An automatic deviation correction device and automatic deviation correction technology are applied in the field of metallurgical steel rolling machinery, which can solve the problems of the unit no longer being able to produce normally, the surface warping of the strip steel, and damaged equipment, etc., and achieve the effects of small space occupation, energy saving, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

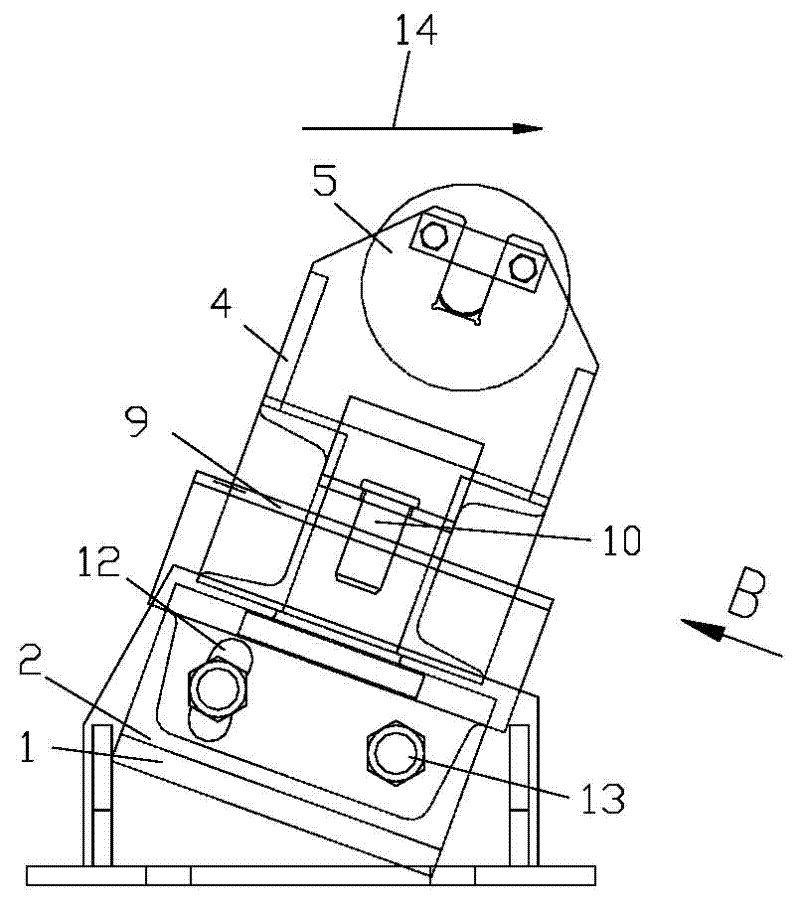

[0017] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

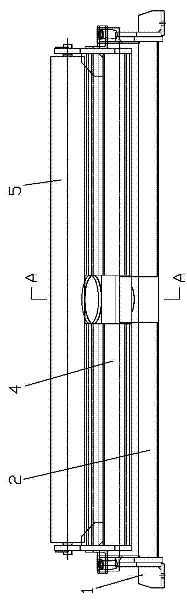

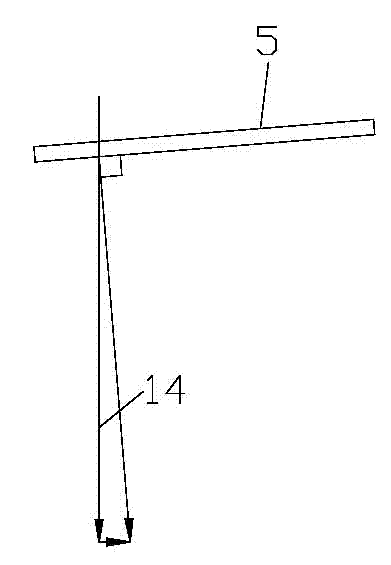

[0018] As shown in the figure, the automatic deviation correction device in the strip rolling equipment involved in the present invention includes a support 1 and a connecting beam 2, and the support 1 and the connecting beam 2 are fixed by fastening screws 13, including The fixed shaft 3, the roller bracket 4 and the automatic deviation correction roller 5, the lower part of the fixed shaft 3 is fixed on the middle position of the two bearings 1 on the connecting beam 2, and the two ends of the automatic deviation correction roller 5 are respectively arranged on the roller support 4, the middle of the bottom of the roller bracket 4 is hinged with the upper end of the fixed shaft 3.

[0019] A circular hole 6 is provided at the middle position of the two supports 1 on the connecting beam 2 , and the lower part of the fixed shaft 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com