Tension control system based on numeric quantity communication mode

A communication mode and tension control technology, which is applied in winding strips, thin material processing, transportation and packaging, etc., can solve the problems of easy attenuation, easy interference of analog values, poor real-time performance, etc., and achieve high real-time performance and stability Good, energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below with reference to the drawings and specific embodiments.

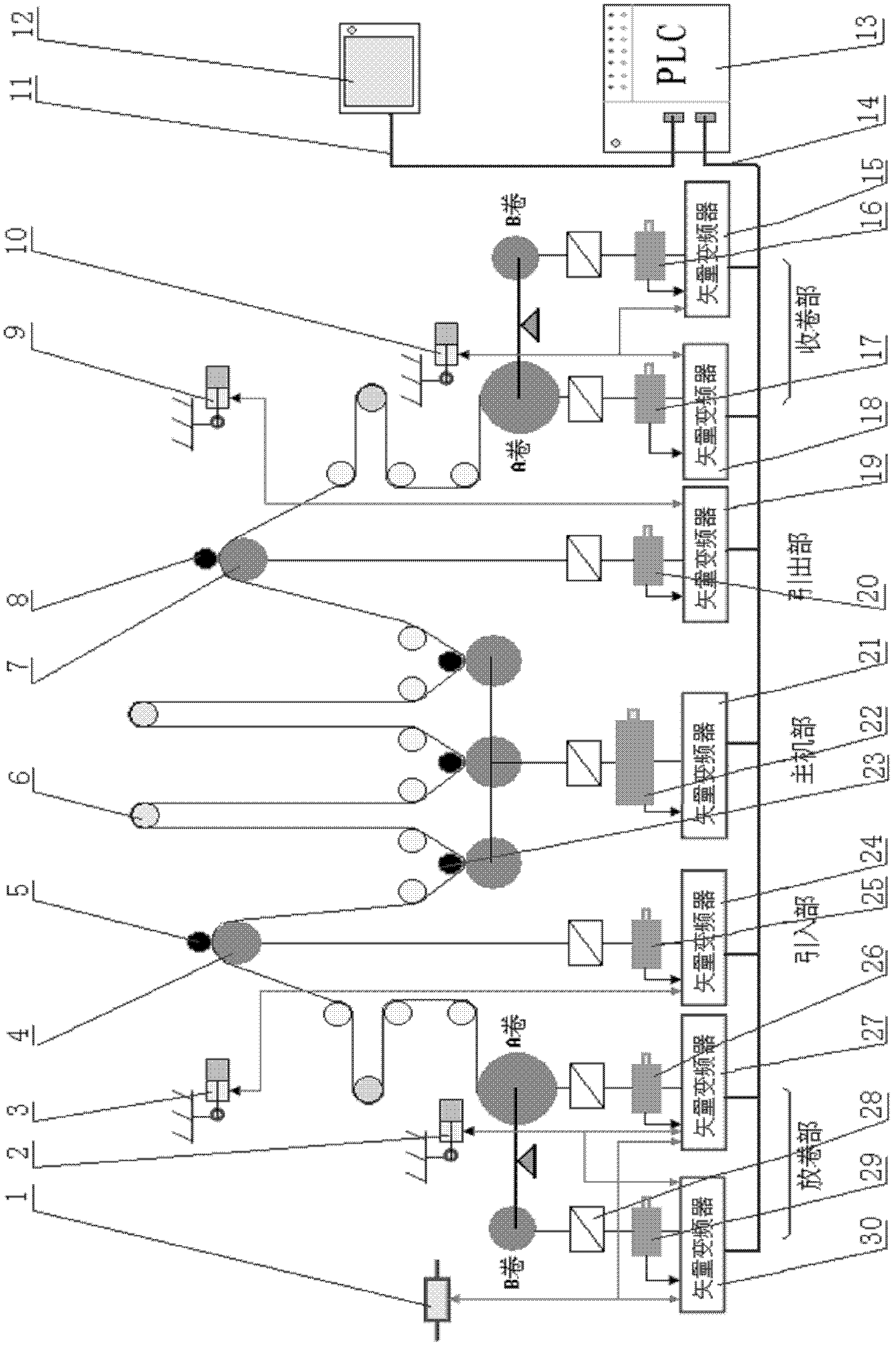

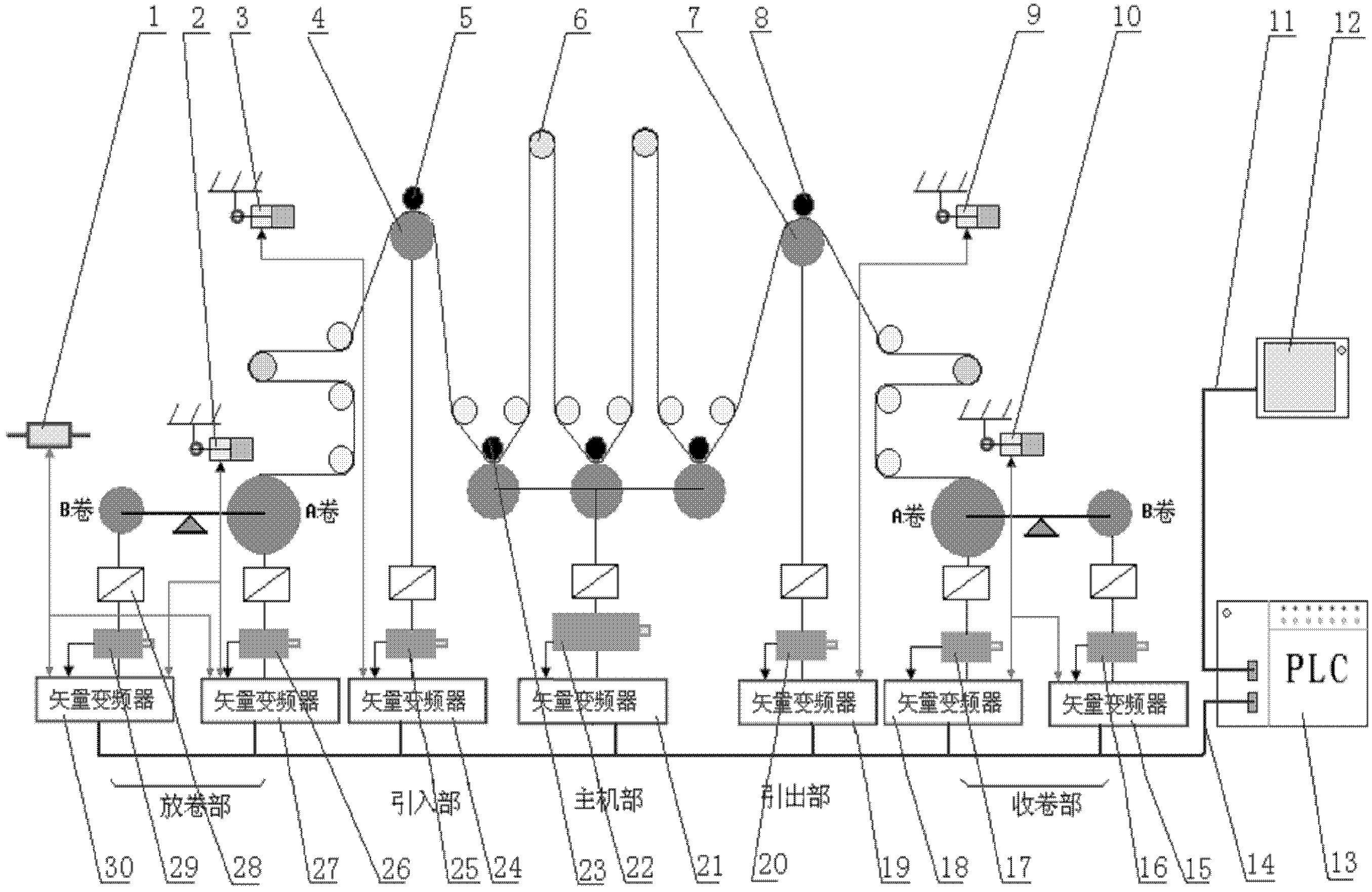

[0016] See figure 1 , The structure of the tension control system based on the numerical value communication mode of the present invention includes PLC, and the unwinding part, the lead-in part, the host part, the lead-out part, and the winding part control part connected with the PLC.

[0017] The unwinding part is provided with an unwinding A-axis inverter 27 and an unwinding B-axis inverter 30. The unwinding B-axis inverter 30 is connected to the B reel through the unwinding B-axis variable frequency motor 29 and its reducer 28, and unwinds The A-axis frequency converter 27 is connected to the A reel through the unwinding A-axis variable frequency motor 26 and its reducer. At the same time, the unwinding diameter detection potentiometer 1 detects the current actual initial diameter of the material film and is directly connected to the unwinding A in an analog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com