Magnetic control sputtering toughened double-silver LOW-eradiation(LOW-E) glass and preparation method thereof

A magnetron sputtering and glass technology, which is applied in the field of preparing temperable double silver LOW-E glass by magnetron sputtering, can solve the problems of loose coating layer, weak bonding force between coating layer and glass substrate, unevenness, etc. Achieve the effect of small color deviation, small drift, and reduced silver consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

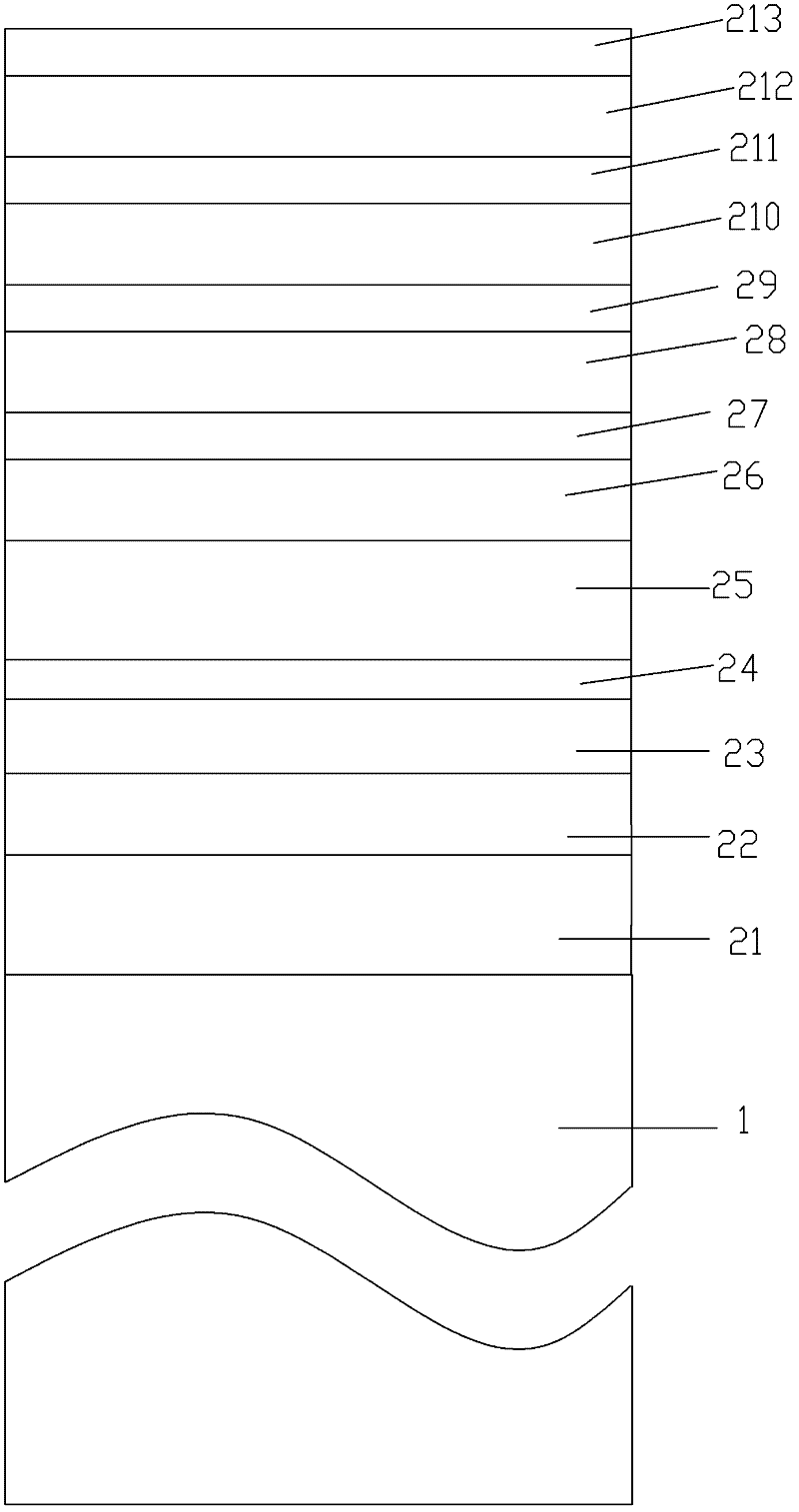

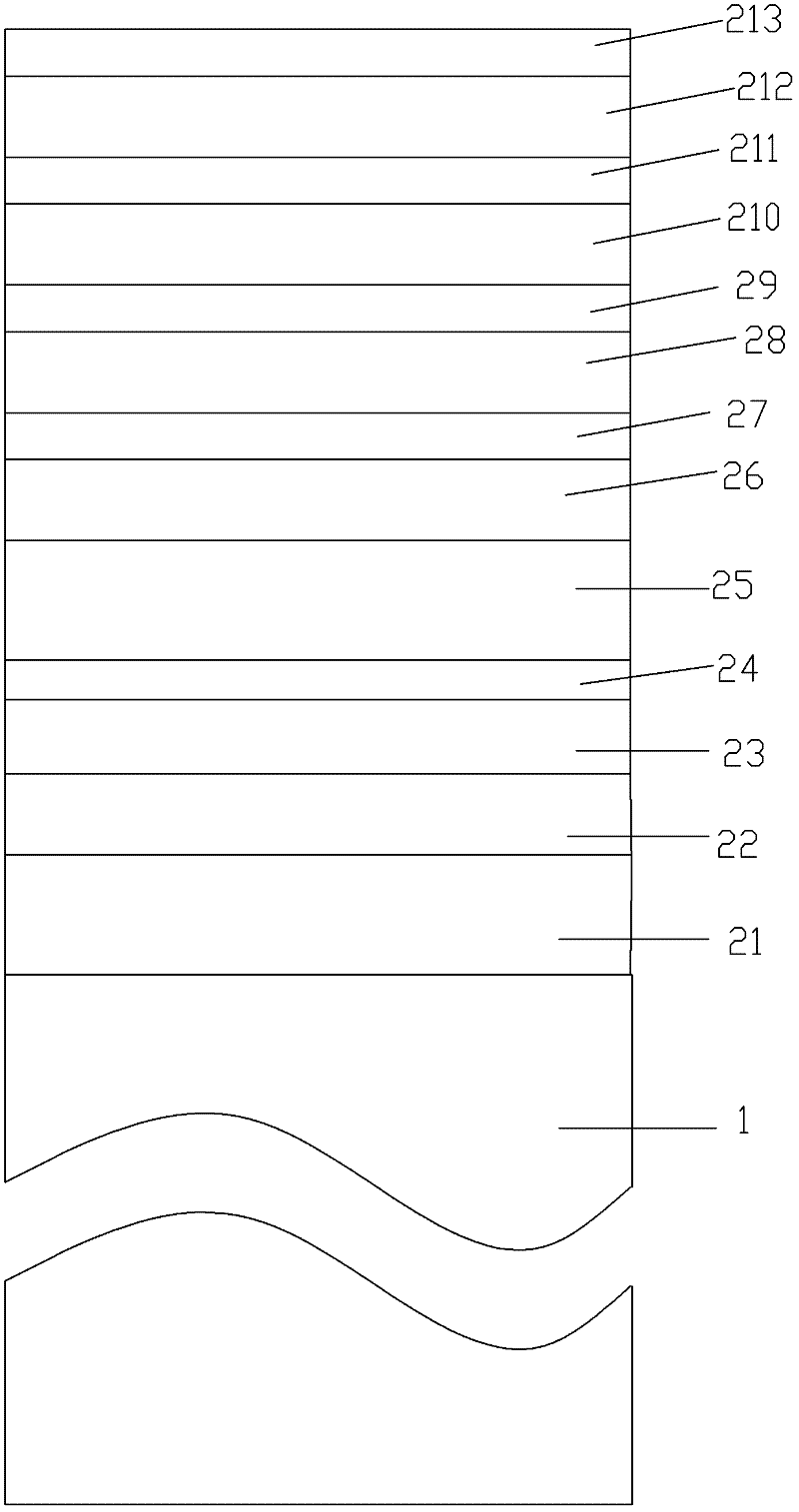

[0027] A magnetron sputtering toughened double-silver LOW-E glass, including a glass substrate 1, on the composite surface of the glass substrate from the inside to the outside, there are thirteen layers of magnetron sputtering adjacent to each other, of which the first One film layer, the innermost layer is SiO 2 Layer 21, the second layer is TiO 2 Layer 22, the third layer is CrN x layer 23, the fourth layer is ZnO layer 24, the fifth layer is Ag layer 25, and the sixth layer is NiCrO y Layer 26, the seventh layer is TiO 2 Layer 27, the eighth layer is ZnSn 3 o 4 layer 28, the ninth layer is ZnO layer 29, the tenth layer is Ag layer 210, and the eleventh layer is NiCrO y Layer 211, the twelfth layer is TiO 2 Layer 212, the outermost layer is Si 3 N 4 o y Layer 213.

[0028] The first film layer SiO 2 Layer 21, the SiO2 layer, is made with TiO 2 Combined with increased refractive index, SiO 2 The thickness is 23~27nm, nm is nanometer, 1m=10 9 nm.

[0029] The T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com