Aqueous wood-wool filling agent coated onto woodware and preparation method thereof

A filler and water-based technology, which is applied in the field of water-based wood wool filler for wood coating and its preparation, can solve the problems of poor paint adhesion, grinding, and long drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

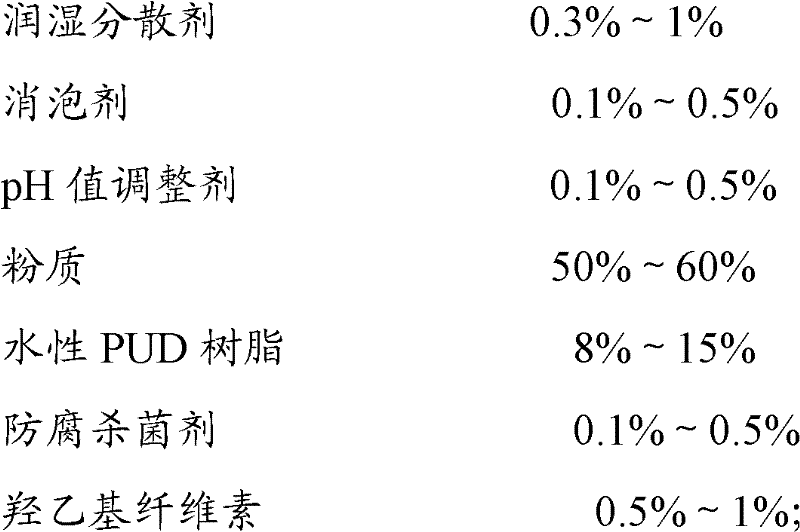

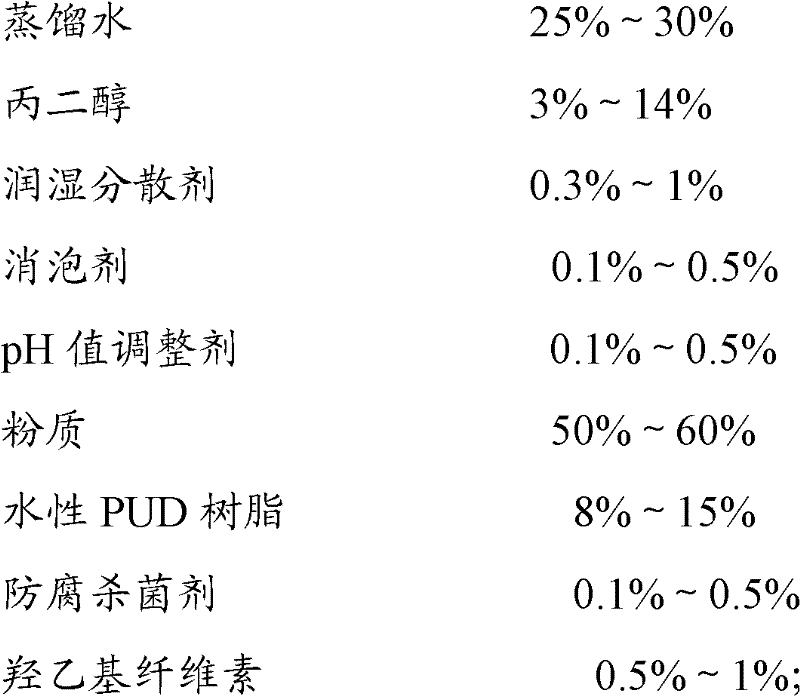

Method used

Image

Examples

Embodiment 1

[0026] A water-based wood wool filler for wood coating, including the following substances calculated by weight percentage:

[0027] Distilled water 20%, propylene glycol 3%, wetting and dispersing agent 0.3%, defoaming agent 0.1%, pH adjuster 0.1%, powdery 60%, water-based PUD resin 15%, antiseptic fungicide 0.5%, hydroxyethyl cellulose 1%.

[0028] Among them, the wetting and dispersing agent is a water-based dispersion wetting agent, the defoaming agent is a water-based defoaming agent, the water-based PUD resin is an aliphatic water-based polyurethane resin, and the antiseptic bactericide is a general water-based paint bactericide.

[0029] The method for preparing the water-based wood wool filler for wood coating includes the following preparation steps:

[0030] Step A. Put the amount of distilled water and propylene glycol into the reactor and stir for 8 minutes at 80 revolutions / min;

[0031] Step B. Put the wetting and dispersing agent and defoaming agent in the reactor, and i...

Embodiment 2

[0035] A water-based wood wool filler for wood coating, including the following substances calculated by weight percentage:

[0036] Distilled water 28%, propylene glycol 5%, wetting and dispersing agent 0.5%, defoaming agent 0.3%, pH adjuster 0.2%, powder 55%, water-based PUD resin 10%, antiseptic bactericide 0.2%, hydroxyethyl cellulose 0.8%.

[0037] Among them, the wetting and dispersing agent is a water-based dispersion wetting agent, the defoaming agent is a water-based defoaming agent, the water-based PUD resin is an aliphatic water-based polyurethane resin, and the antiseptic bactericide is a general water-based paint bactericide.

[0038] The method for preparing the water-based wood wool filler for wood coating includes the following preparation steps:

[0039] Step A: Put the amount of distilled water and propylene glycol into the reactor and stir for 5 minutes at 100 revolutions / min;

[0040] Step B. Put the said amount of wetting and dispersing agent and defoaming agent in...

Embodiment 3

[0044] A water-based wood wool filler for wood coating, including the following substances calculated by weight percentage:

[0045] Distilled water 25.4%, propylene glycol 13%, wetting and dispersing agent 1%, defoaming agent 0.5%, pH adjuster 0.5%, powdery 50%, water-based PUD resin 8%, antiseptic fungicide 0.1%, hydroxyethyl cellulose 0.5%.

[0046] Among them, the wetting and dispersing agent is a water-based dispersion wetting agent, the defoaming agent is a water-based defoaming agent, the water-based PUD resin is an aliphatic water-based polyurethane resin, and the antiseptic bactericide is a general water-based paint bactericide.

[0047] The method for preparing the water-based wood wool filler for wood coating includes the following preparation steps:

[0048] Step A. Put the amount of distilled water and propylene glycol into the reactor and stir for 3 minutes at 120 rpm;

[0049] Step B. Put the wetting and dispersing agent and defoaming agent in the reactor, and increase t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com