Spinning dope filter

A filter and slurry technology, which is applied in the filtration of spinning solution, defoaming of spinning solution, and filament forming treatment, etc., can solve the problems of difficult cleaning, affecting production, and agglomeration of slurry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

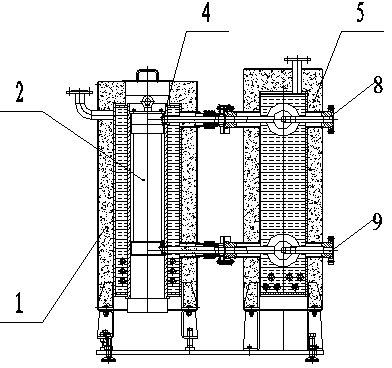

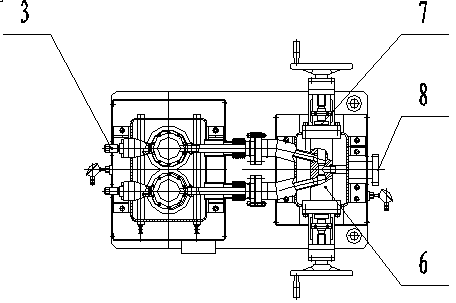

[0014] see figure 1 , the overall structure of the traditional filter is divided into two parts, the filter device is on the left, and the switching device is on the right, and the two are connected by flanges.

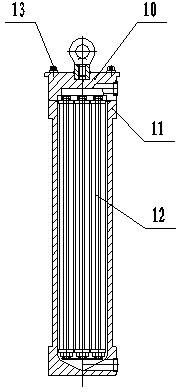

[0015] The filter device on the left includes a body 1 and two filter cartridges 2. The body 1 is a jacketed structure with heat preservation. The jacket is equipped with an electric heating tube to heat the heat-conducting oil or other heating media added to the jacket. The whole body is provided with two through chambers, each chamber has an independent pulp inlet pipe and outlet pipe, and the inlet and outlet pipes are short straight pipes, one end of which is inside the chamber, and the other end is outside the body with a mounting flange. The two filter cartridges 2 are put into the two cavities of the machine body 1 respectively, and are aligned with the inlet and outlet slurry pipes in the cavity by the gasket 3 and locked by the ejector rod 4 . When cleaning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com