Foaming device for foamed asphalt

A technology of foaming device and foamed asphalt, which is applied to spraying devices, spraying devices, roads, etc., can solve the problems of unclean cleaning and low foaming efficiency, and achieve the effect of improving quality and solving scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to better understand the technical solutions of the present invention, the embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

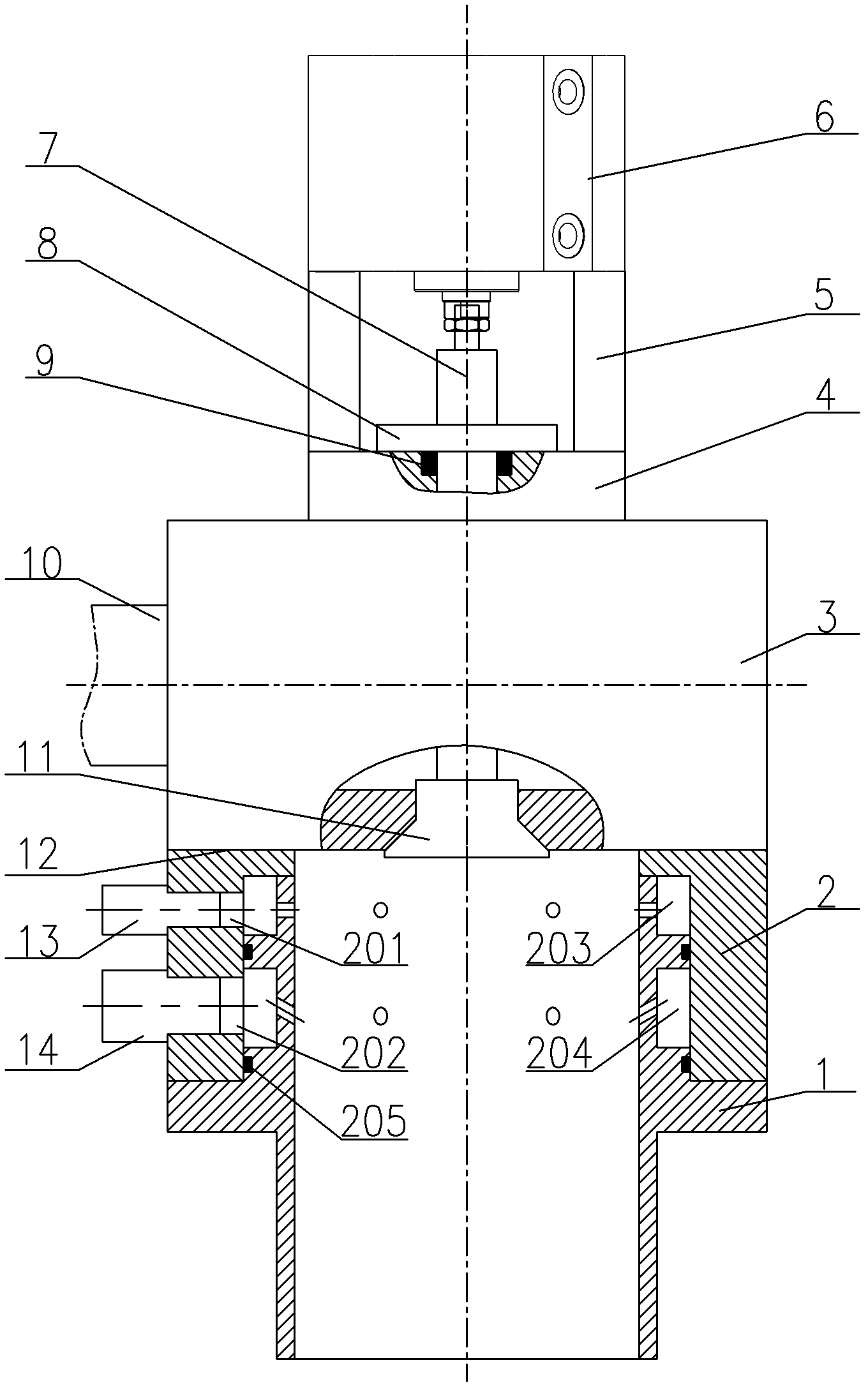

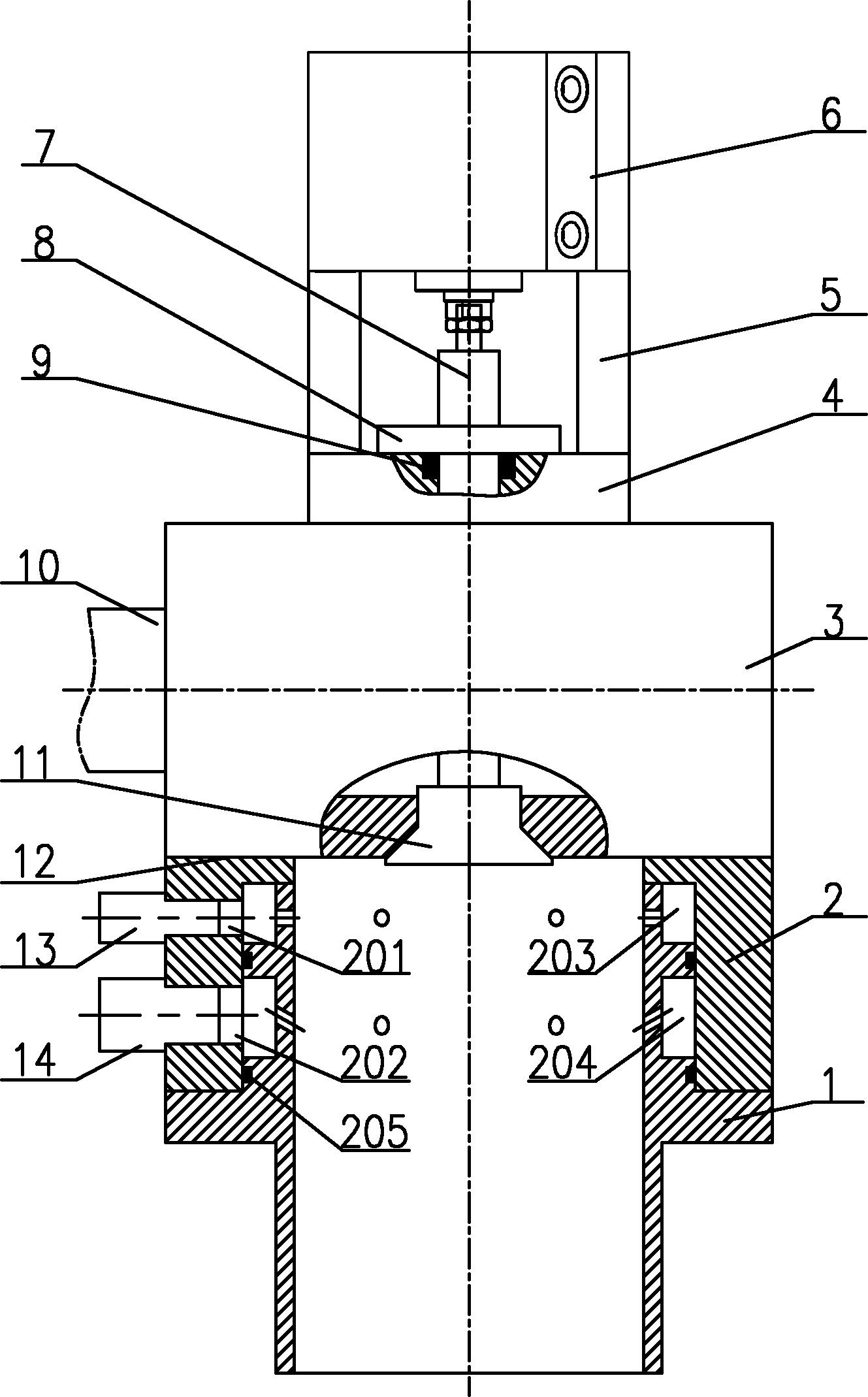

[0018] refer to figure 1 As shown, the foamed asphalt generating device includes: foaming nozzle body 1, kit 2, asphalt pipe 3, fixed sleeve 4, cylinder support 5, cylinder 6, tie rod 7, guide sleeve 8, seal 9, asphalt pipe interface 10 , Cut-off piece 11, gasket 12, water nozzle 13, compressed air nozzle 14.

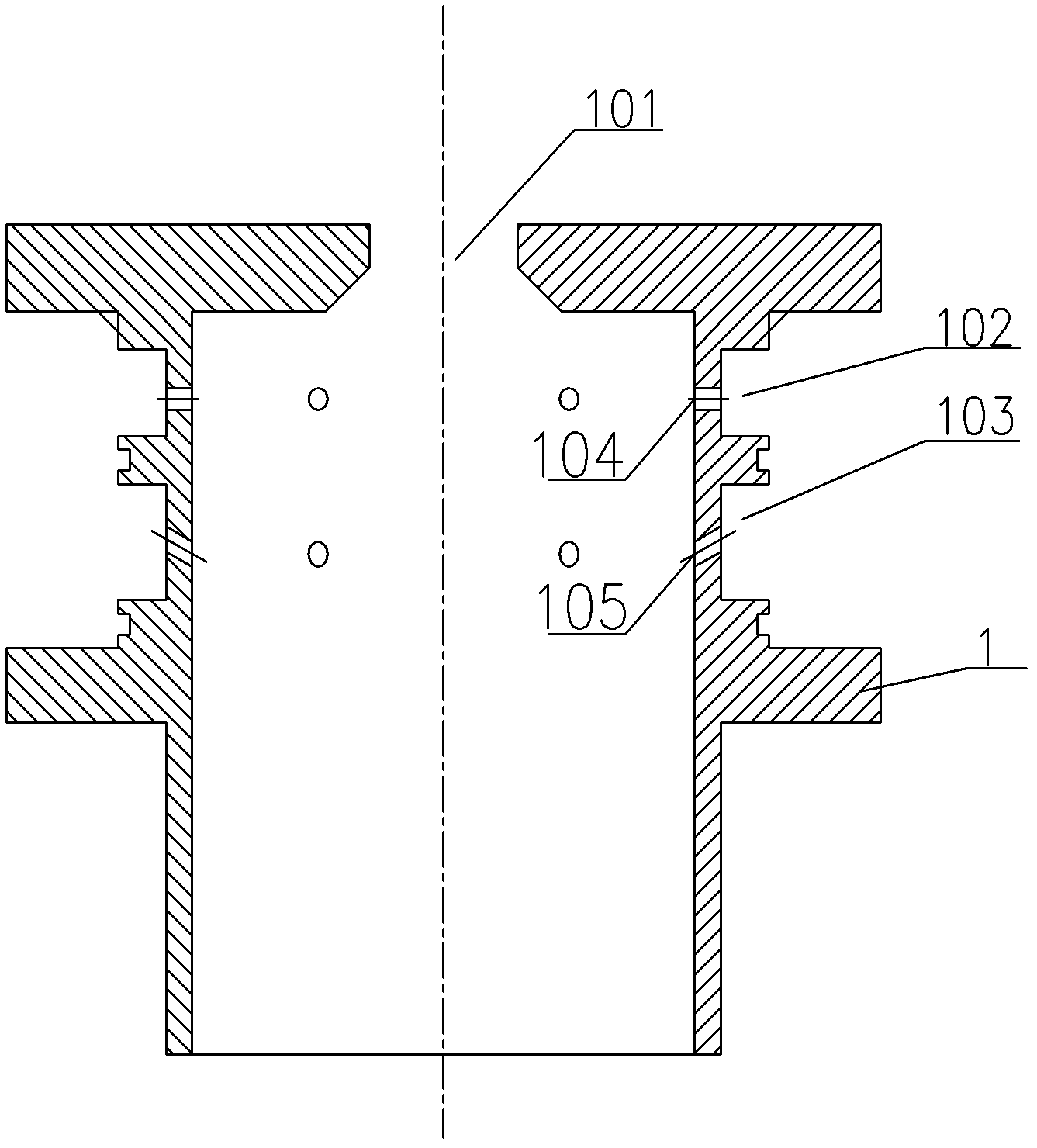

[0019] refer to figure 1 , 2 As shown, the foaming nozzle main body 1 has an asphalt spout 101 in the center of its top, and the outer wall of the nozzle main body 1 is formed with two upper and lower parallel first annular grooves 102 centered on the foaming nozzle 102 and the second Annular groove 103, the side walls of the first and second annular grooves are uniformly provided with water spout 104 and air spout 105 communicating with the foaming c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com